Air inlet channel structure of hydraulic retarder venting device

A hydraulic retarder and ventilation device technology, applied in the direction of liquid resistance brakes, brake types, mechanical equipment, etc., can solve the problems of air leakage into the working chamber and affect the work of the hydraulic retarder, so as to increase the service life And performance, the effect of media oil recovery promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

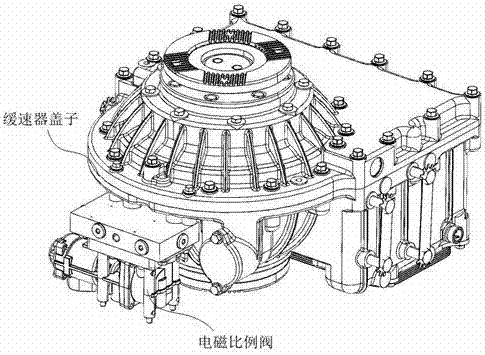

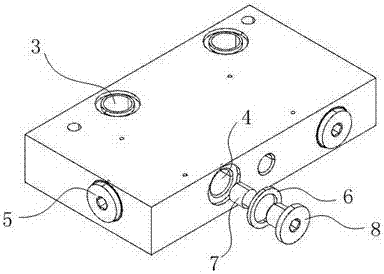

[0019] like Figure 1-3 As shown, the present invention discloses an air inlet structure of a hydraulic retarder ventilator. The ventilator is a rectangular structure, and the upper surface of the ventilator is provided with two sets of circular openings connected with the hydraulic retarder shell. There are two sets of circular openings connected to the electromagnetic proportional valve on the lower surface, several circular openings are opened on the side of the ventilation device, two sets of air inlets are arranged in the ventilation device, and the upper The circular openings on the surface and the circular openings on the sides communicate with each other to form an airway structure.

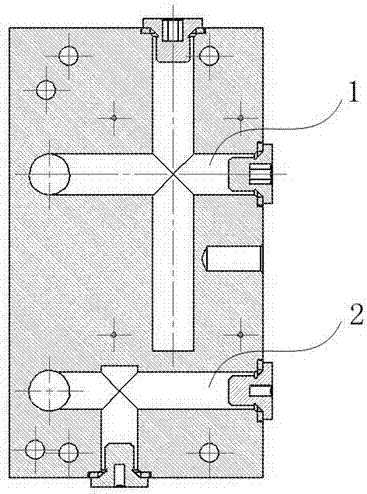

[0020] The air inlets are respectively a group of cross-shaped structure air inlets 1 and a group of T-shaped structure air inlets 2. The air inlets all use circular openings on the upper surface of the ventilation device as air inlets 3, and the air inlets on the side of the ventilation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com