Mountain tunnel mechanized construction method based on high pressure carbon dioxide cracking

A high-pressure carbon dioxide, construction method technology, applied in tunnels, earthwork drilling, mining equipment and other directions, can solve the problems of reducing the self-stabilizing ability of surrounding rock, difficult management in the cave, rock disturbance around the cave, etc. The effect of saving working time and improving self-stable ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments.

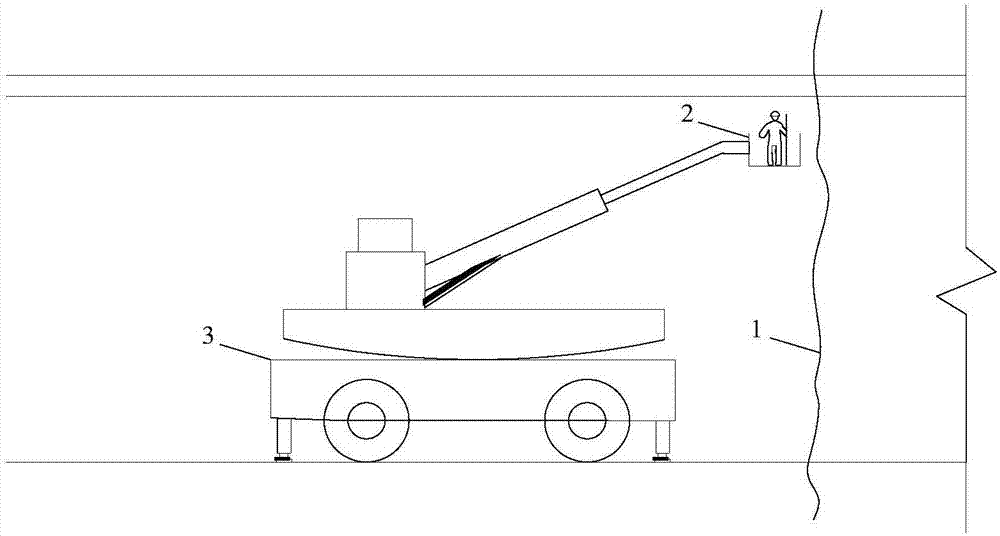

[0031] During the mechanized construction of mountain tunnels based on high-pressure carbon dioxide fracturing, such as figure 1 As shown, a mechanized construction method for mountain tunnels based on high-pressure carbon dioxide fracturing includes the following steps:

[0032] Step 1), use the professional drilling equipment of excavating and modifying the drilling rig (refitting the excavator, adding a drilling rig) to drill holes at the designated positions on the face of the face, and the diameter and length of the drilling must be controlled within a reasonable range.

[0033] Step 2), use a long-arm forklift with its own operating platform, which can carry workers to fill carbon dioxide detonators at different positions, and arrange detonating lines at the same time. When performing carbon dioxide detonator filling, wiring, sealing and other processes, strict comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com