Foundation pile top quick reinforcement method

A pile top and foundation pile technology, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problems of long time, affecting the construction period and low strength of the pile top structure, so as to achieve the effect of saving construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

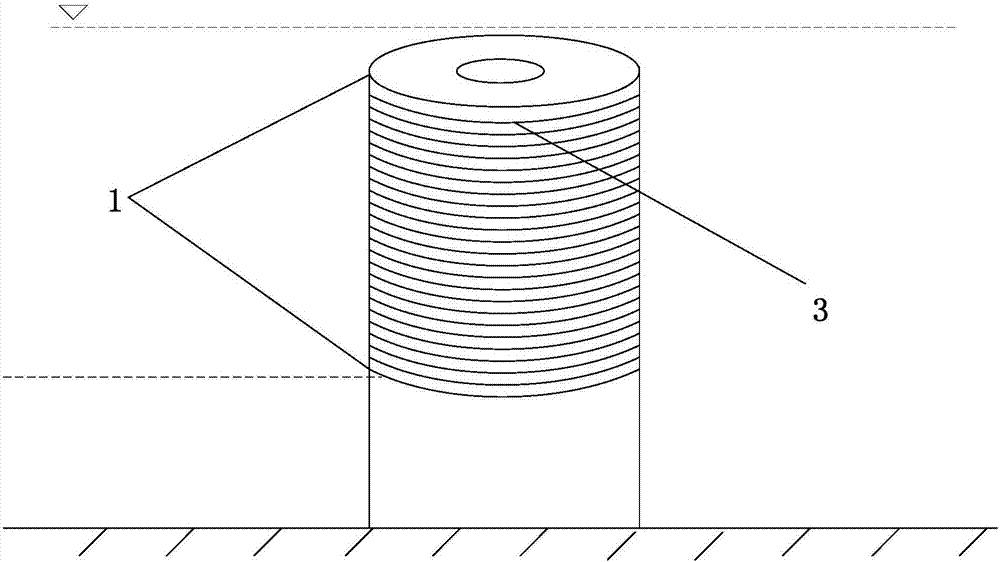

[0022] Remove the concrete above the design elevation of the prefabricated pile (PHC pile), and use the area from the design elevation to the 50cm position of the prefabricated pile body as the reinforcement section 1 of the prefabricated pile. A plurality of steel bars tightly attached to the outer surface of the side wall, the diameter of the steel bars is 6mm, and the two ends of each steel bar are welded to form a closed ring bar 3, and the distance between the ring bars 3 is about 50mm. The ring bars 3 are close to parallel to each other, and the gap between the pile top and the pile body and the gap between the ring bars and the pile body are smoothed with structural glue. The pile top, pile body and ring bars form a whole to facilitate the foundation pile Bearing capacity detection, the processed prefabricated pile heads are as follows: figure 1 shown.

Embodiment 2

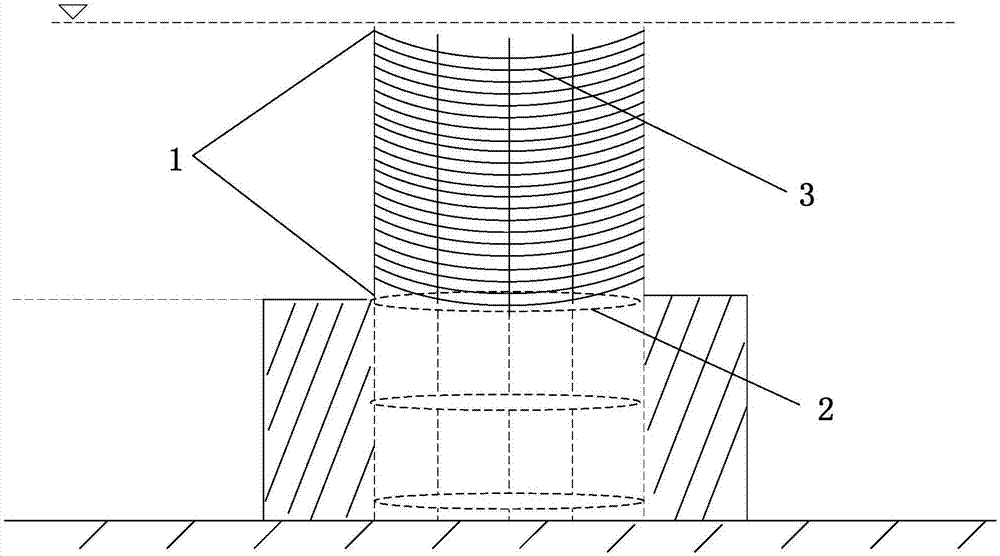

[0024] Remove the concrete above the longitudinal reinforcement (main reinforcement) of the cast-in-place pile, and remove the protective layer concrete from the top of the longitudinal reinforcement (main reinforcement) of the cast-in-place pile to the first stirrup of the pile body and the outer periphery of the longitudinal reinforcement (main reinforcement) to form the reinforcement section of the cast-in-place pile 1. Along the outer surface of the side wall of the reinforcement section 1, a plurality of steel bars that are closely attached to the outer surface of the side wall are tightly wrapped in a circumferential direction. The diameter of the steel bars is 8mm, and the joints at both ends of each steel bar are welded to form a closed ring bar 3. The distance between the ring bars 3 is about 50mm, and the ring bars 3 are close to parallel to each other. Use the grouting material to smooth the gap between the pile top and the pile body and the gap between the ring bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com