Wear-resisting compound heel lift and preparation method thereof

A sky skin and super wear-resistant technology, applied in the field of shoe skins, can solve the problems of small friction, low hardness of composite materials, complex production process, etc., and achieve the effect of improving service life and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

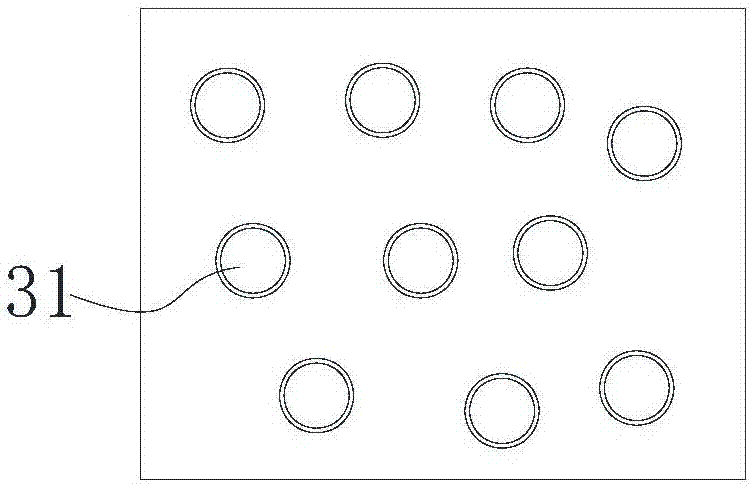

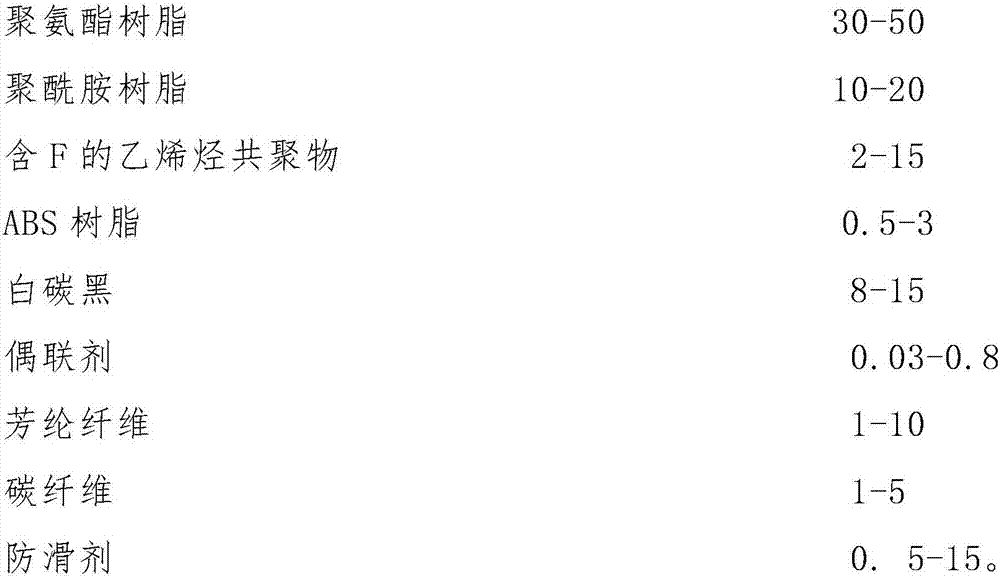

[0033] A wear-resistant composite sky skin is made of the following components in parts by weight:

[0034]

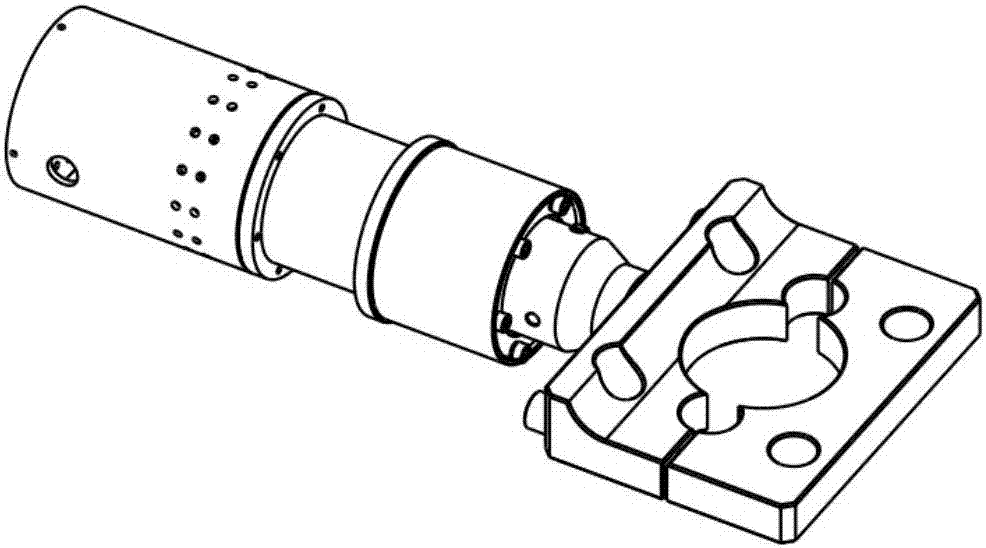

[0035] The preparation method of above-mentioned wear-resistant composite sky skin, the steps that it comprises are as follows:

[0036] (1) Get polyurethane resin, polyamide resin, F-containing ethylene copolymer, ABS resin, white carbon black, coupling agent, aramid fiber, carbon fiber, anti-skid agent according to the above-mentioned ratio of parts by weight respectively and mix uniformly,

[0037] (2) Import the mixed material in the step (1) into the hopper of the injection molding machine, and inject it into a mold at 260° C. to form a top skin, and a top skin with a contact area of 2.3 square centimeters can be obtained. The friction test was carried out by using a Tianpi wear-resistant testing machine, and the wear thickness of 100 frictions was 50 microns; the hardness measured by the Shore hardness tester was 81.

Embodiment 2

[0039] A wear-resistant composite sky skin is made of the following components in parts by weight:

[0040]

[0041]

[0042] The preparation method of above-mentioned wear-resistant composite sky skin, the steps that it comprises are as follows:

[0043] (1) Get polyurethane resin, polyamide resin, F-containing ethylene copolymer, ABS resin, white carbon black, coupling agent, aramid fiber, carbon fiber, anti-skid agent according to the above-mentioned ratio of parts by weight respectively and mix uniformly,

[0044] (2) Import the mixed material in the step (1) into the hopper of the injection molding machine, and inject it into a mold at 250° C. to form a top skin, and a top skin with a contact area of 2.3 square centimeters can be obtained. The friction test was carried out with a Tianpi wear-resistant testing machine, and the wear thickness of 100 times of friction was 49 microns; the hardness measured by the Shore hardness tester was 87.

Embodiment 3

[0046] A wear-resistant composite sky skin is made of the following components in parts by weight:

[0047]

[0048] The preparation method of above-mentioned wear-resistant composite sky skin, the steps that it comprises are as follows:

[0049] (1) Get polyurethane resin, polyamide resin, F-containing ethylene copolymer, ABS resin, white carbon black, coupling agent, aramid fiber, carbon fiber, anti-skid agent according to the above-mentioned ratio of parts by weight respectively and mix uniformly,

[0050] (2) Import the mixed material in the step (1) into the hopper of the injection molding machine, and inject it into a mold at 250° C. to form a top skin, and a top skin with a contact area of 2.3 square centimeters can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com