Portal frame special for device installation of urban rail traffic power supply system

A technology of urban rail transit and power supply system, which is applied in the field of installation and construction of urban rail transit power supply system equipment, which can solve problems such as cabinet damage, wall top pollution, and tediousness, so as to improve installation efficiency, reduce safety risks, and facilitate disassembly and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with specific embodiment:

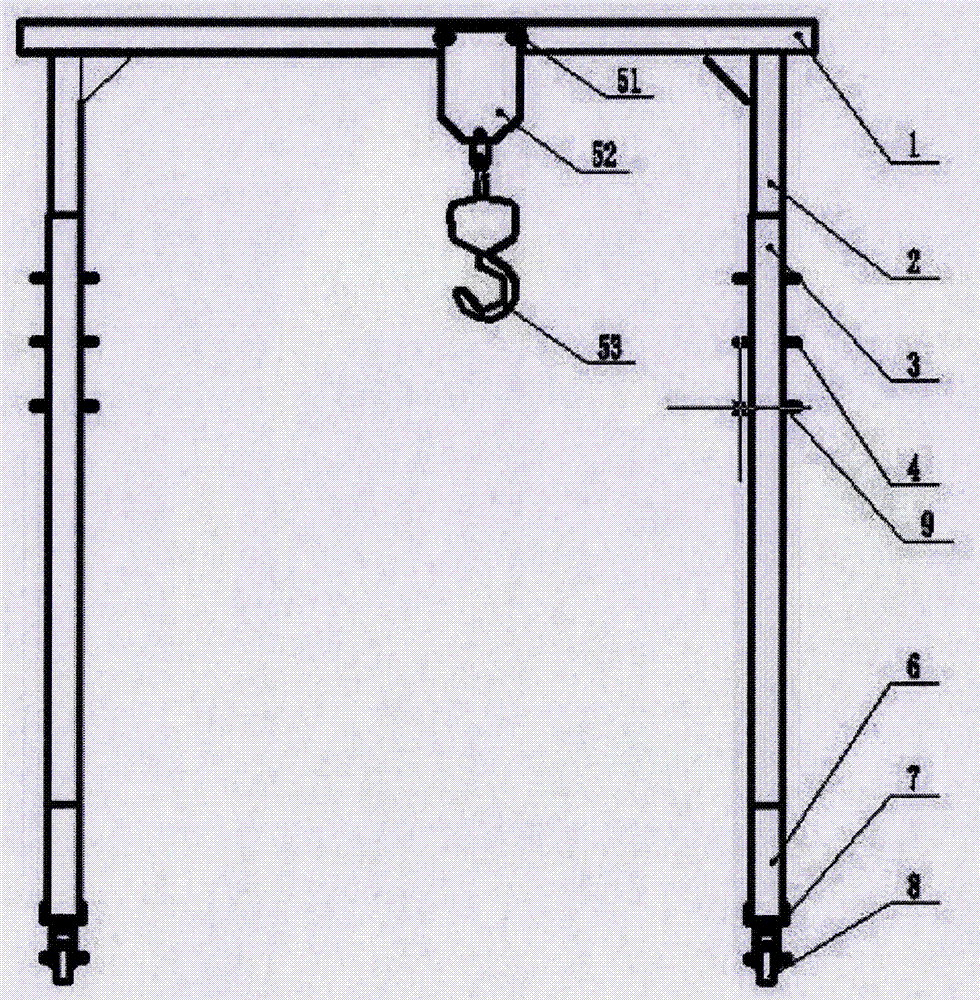

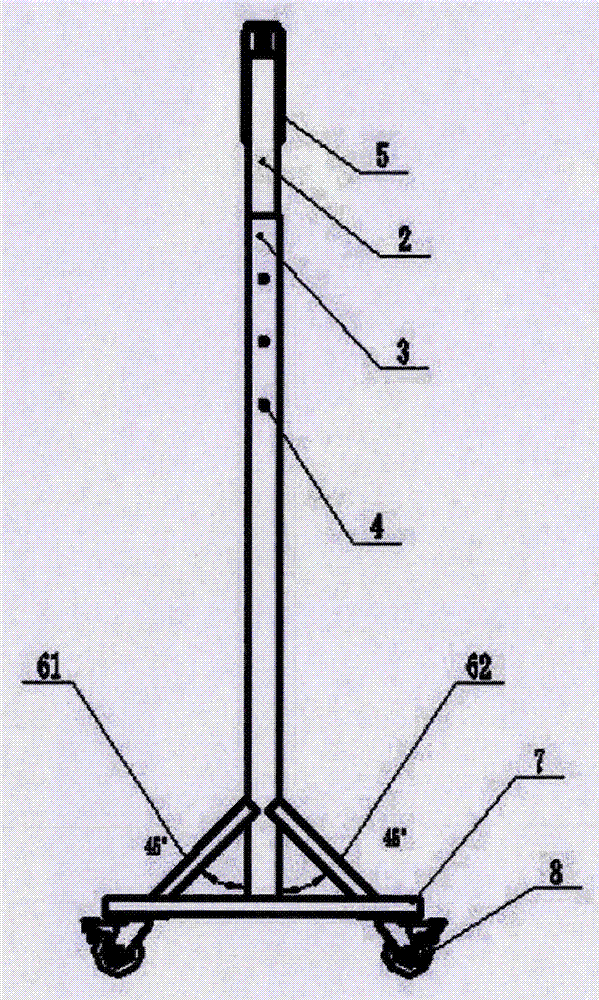

[0022] Such as figure 1 and figure 2 As shown, a gantry dedicated to the installation of urban rail transit power supply system equipment includes a crossbeam 1, which is an H-shaped I-beam, and is respectively connected to the first column 2 on both sides of the crossbeam 1. The bottom of the first column 2 is correspondingly connected with the second column 3, and the first column 2 expands and contracts up and down inside the second column 3, and the bottom of the second column 3 is correspondingly connected with the channel steel 7 of the base. The second column 3 is provided with a plurality of positioning through holes 9, and the positioning through holes 9 are correspondingly connected with the positioning pins 4 passing through the second column 3, and the bottom of the base channel steel 7 corresponds to the universal caster 8 To connect, a moving pulley 5 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com