Test and Test Jitter Platform and Its Jitter Method

A jitter platform and testing technology, applied in the field of detection, can solve the problems of large jitter amplitude and inability to meet the requirements of "anti-shake" detection, and achieve the effect of reducing offset, improving precision and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

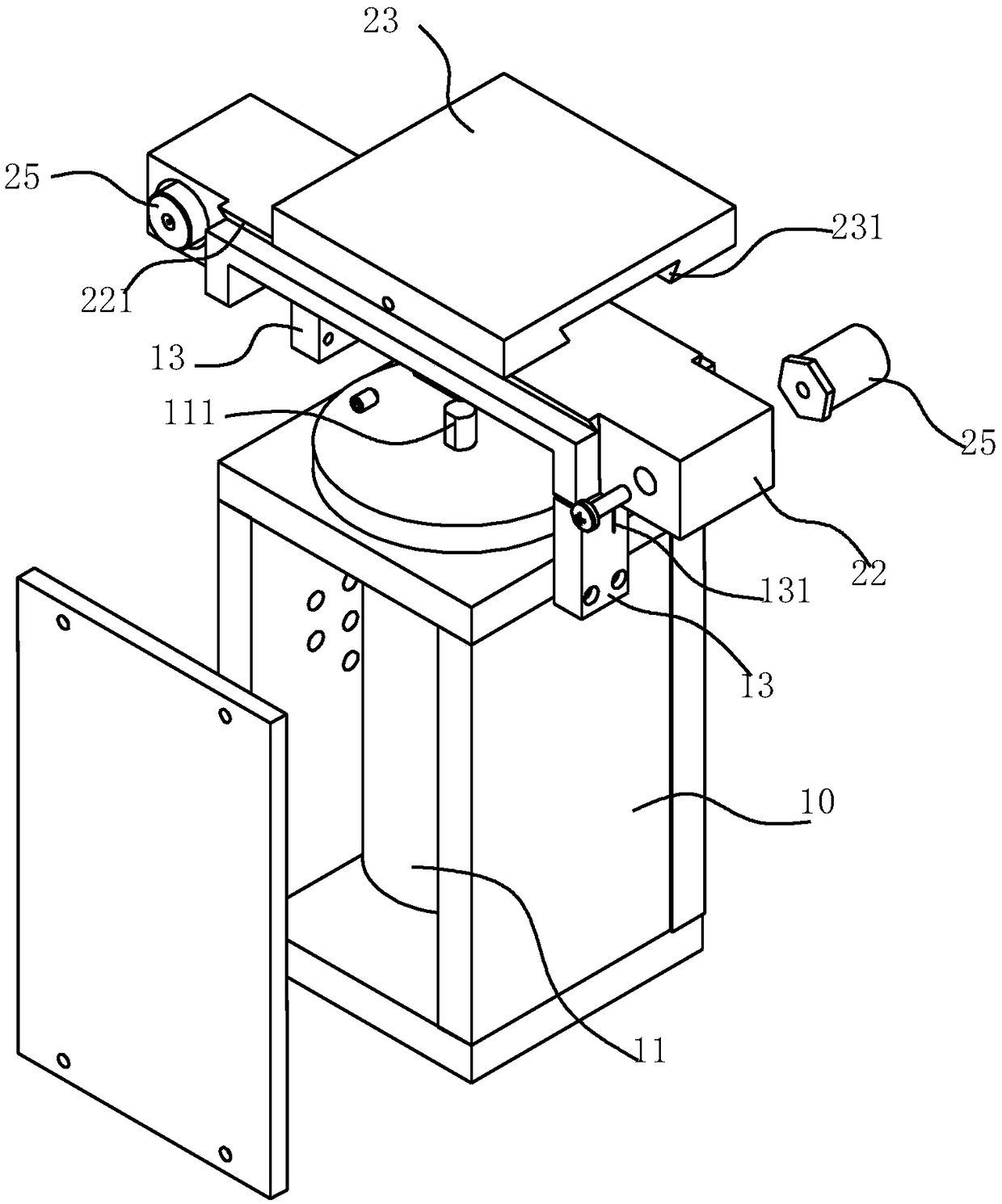

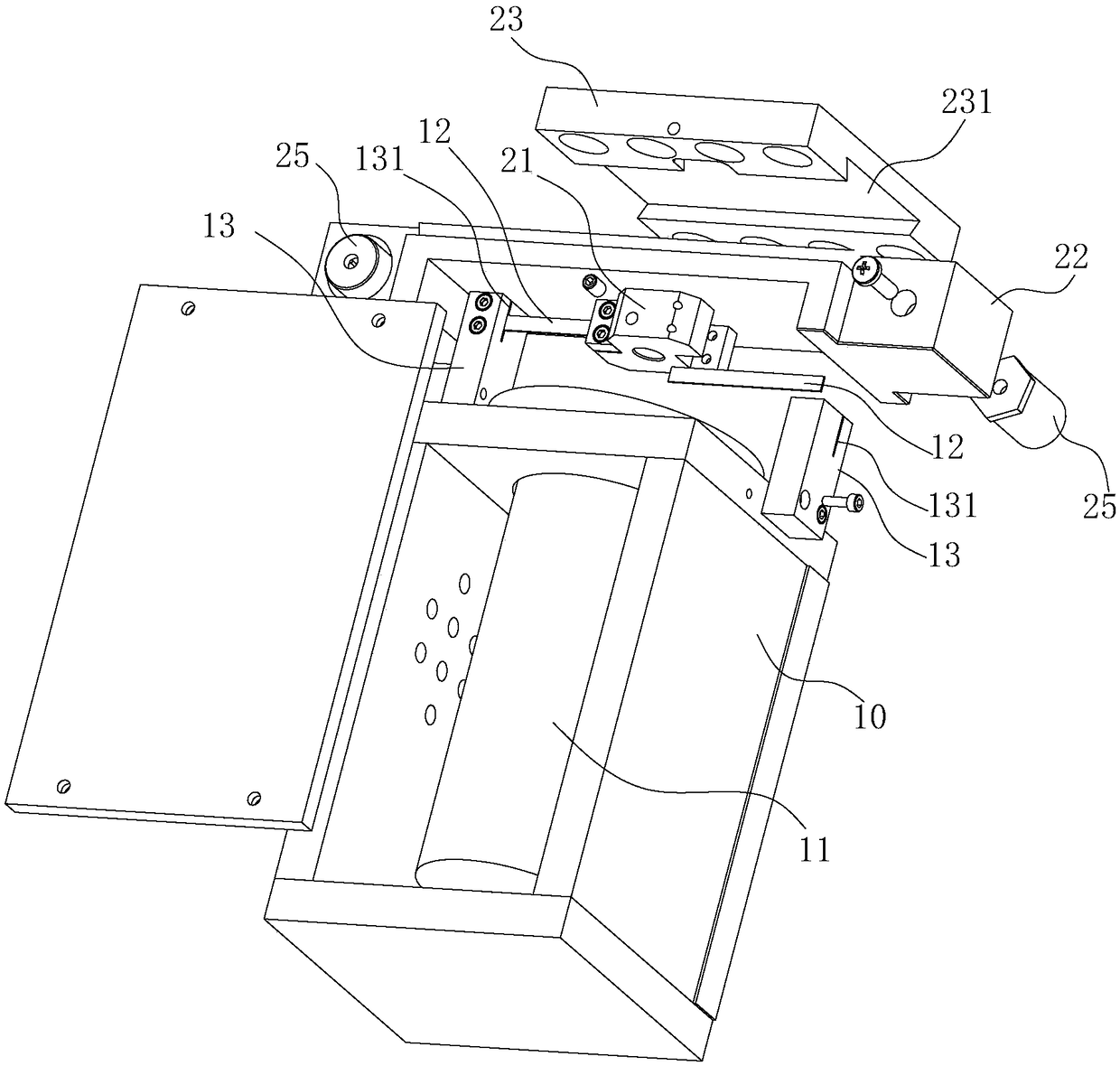

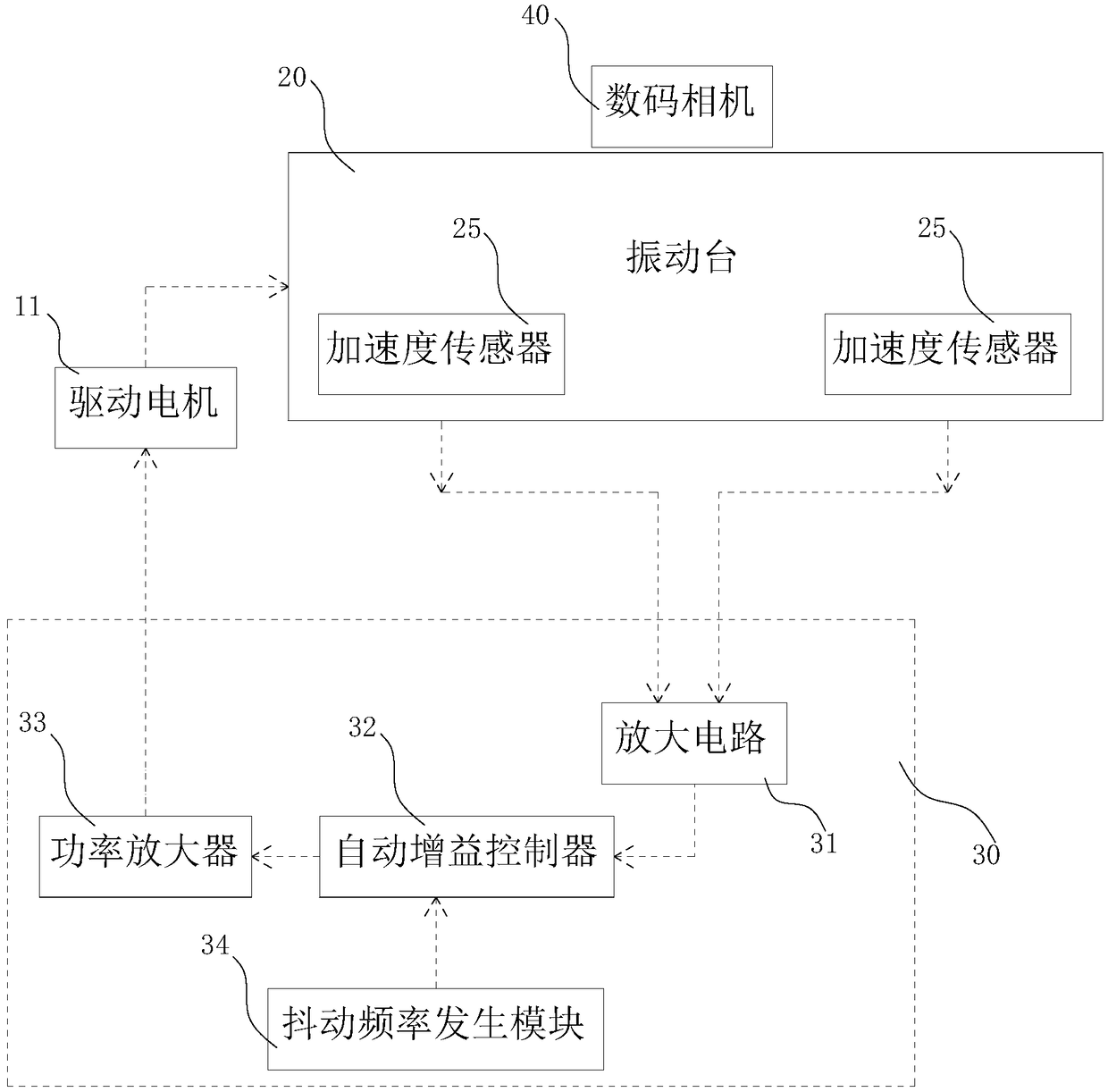

[0039] like figure 1 , figure 2 and image 3As shown, the detection test shake platform is used to test the anti-shake performance of the digital camera 40. It includes a body 10 and a vibration table 20. The body 10 is provided with a drive motor 11 and a drive motor 11 Electrically connected with the control circuit 30, the drive motor 11 has a vibrating output shaft 111 facing upwards, and a shaft coupling 21 is provided below the vibrating table 20, and the coupling 21 is connected to the upper end of the vibrating output shaft 111. The vibrating table 20 Located above the vibration output shaft 111 , an elastic vibration limiting member 12 is provided between the body 10 and the vibrating table 20 .

[0040] Wherein, the shaking limiting member 12 is an elastic metal strip, and there are two shaking limiting members 12 located on two opposite sides of the coupling 21 . The fuselage 10 is provided with a limit column 13, and the limit column 13 is provided with a limit...

Embodiment 2

[0055] like Figure 4 , Figure 5 As shown, in this embodiment, the vibrating table 20 further includes a side table 24 , one side of the side table 24 is connected to one side of the fixed table 23 . One side of the side platform 24 is connected to one side of the fixing platform 23, and the digital camera 40 can be installed and fixed as required to meet different installation or detection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com