Single-view three-dimensional ultrasonic nondestructive detection system and method

A non-destructive testing and monocular vision technology, applied in the analysis of solids, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, to achieve the effects of ensuring measurement accuracy, improving detection efficiency, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

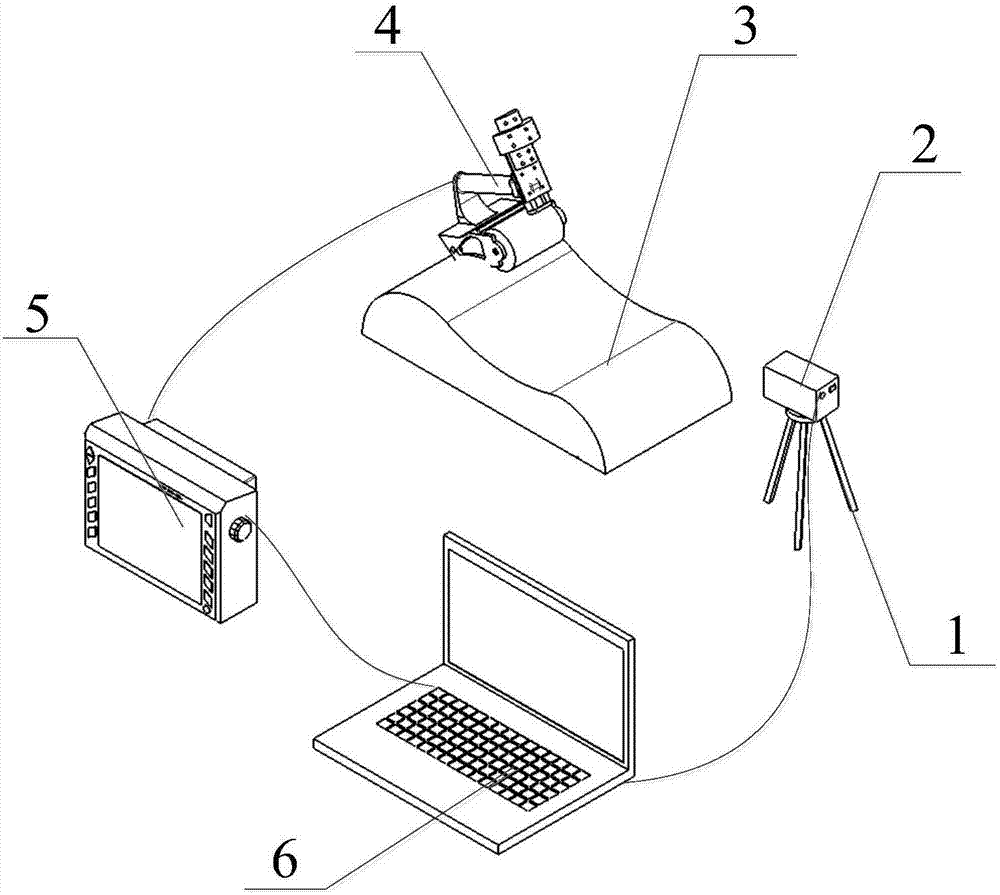

[0045] Such as figure 1 As shown, the monocular vision three-dimensional ultrasonic nondestructive testing system includes camera bracket 1, CCD high-speed camera 2, curved surface / plane measured workpiece 3, ultrasonic conventional phased array probe reflection target 4, advanced eddy current, ultrasonic phased array host system 5 , processing system workstation 6. Wherein, the CCD high-speed camera 2 is fixed on the camera bracket 1 through threaded connection and the CCD high-speed camera 2 is connected with the processing system workstation 6 through a data line, and the CCD high-speed camera 2 acquires the ultrasonic conventional phased array probe reflection target 4 and the curved surface / plane in real time. Measure the positional relationship between workpieces 3 and transmit the test results to the workstation; advanced eddy current, ultrasonic phased array host system 5 and ultrasonic conventional phased array probe reflection target 4 are connected through data tran...

Embodiment 2

[0059] Such as figure 2 As shown, the monocular vision three-dimensional ultrasonic non-destructive testing system includes camera bracket 1, CCD high-speed camera 2, curved surface / plane measured workpiece 3, advanced eddy current, ultrasonic phased array host system 5, processing system workstation 6, ultrasonic wheel phase The array probe reflects the target 7 . Among them, the CCD high-speed camera 2 is fixed on the camera bracket 1 through threaded connection; the advanced eddy current, ultrasonic phased array host system 5 and the ultrasonic wheel phased array probe reflection target 7 are connected through data transmission lines to display the ultrasonic detection results in real time; the advanced eddy current , The ultrasonic phased array host system 5 is connected with the processing system workstation 6 through a data line at the same time, and transmits the detection results to the workstation.

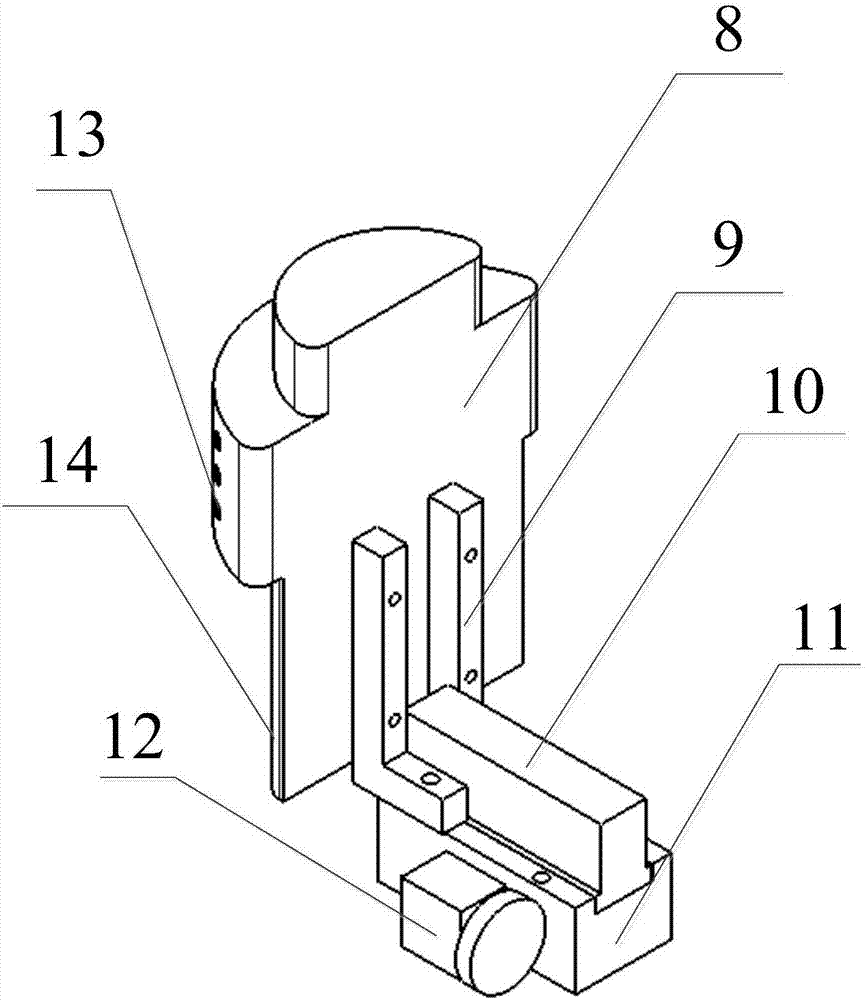

[0060] Such as Figure 5As shown, the ultrasonic wheel-type phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com