Planar optical element absolute surface shape detection device

A technology of optical components and detection devices, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of losing medium and high frequency information of the wave front, affecting the accuracy of absolute detection and measurement, and incomplete plane shape information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with embodiment, but should not limit the transformation range of the present invention with this.

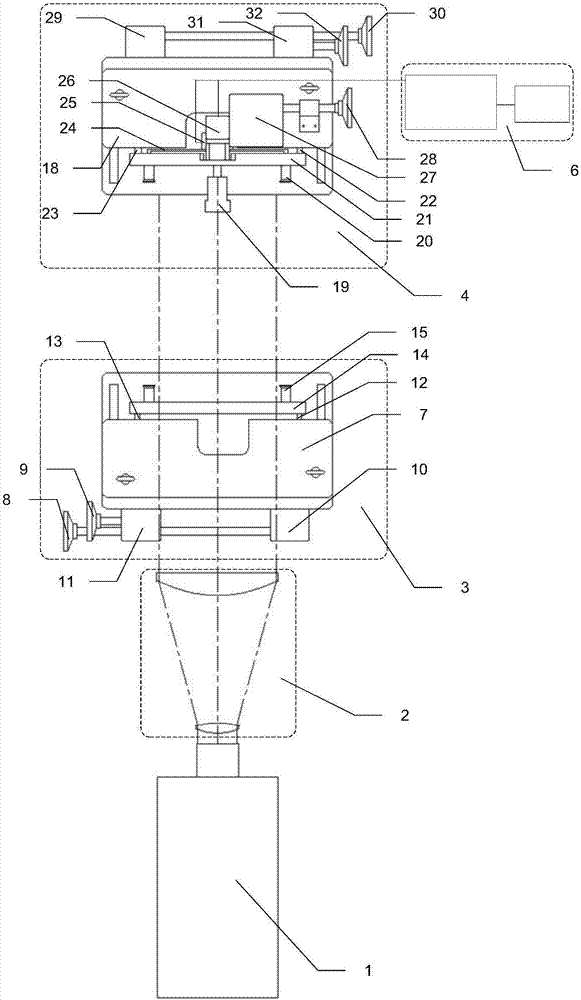

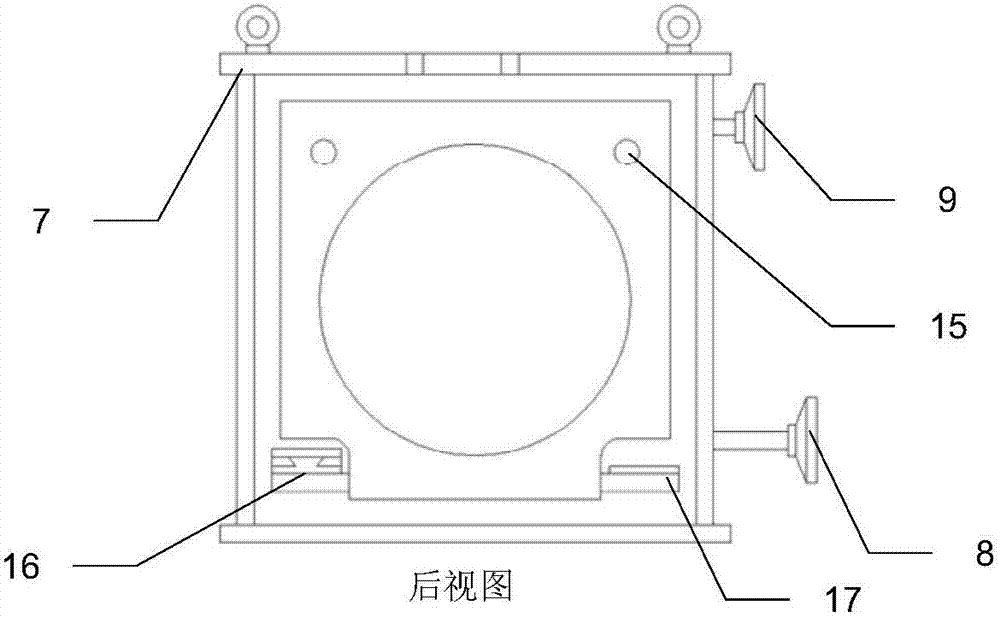

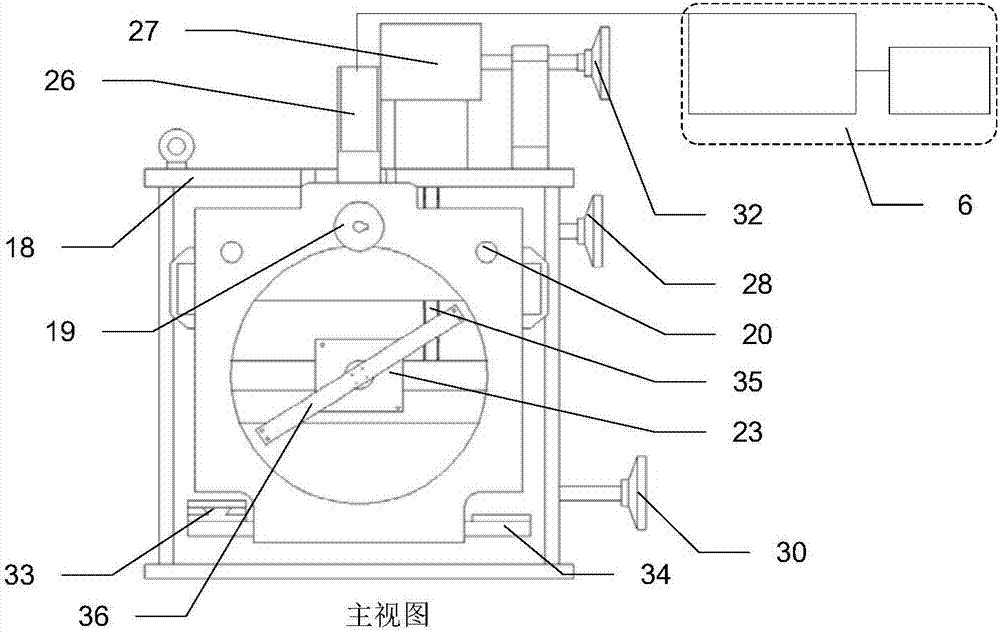

[0049] see first figure 1 , figure 2 , image 3 , Figure 4 , figure 1 It is a top view of the absolute surface shape detection device of the planar optical element of the present invention; figure 2 is the rear view of the transmission mirror two-dimensional adjustment system; image 3 Front view of the mirror four-dimensional adjustment system; Figure 4 It is the front view of the planar optical element fixture; as can be seen from the figure, the composition of the best embodiment of the absolute surface shape detection device of the planar optical element of the present invention includes a laser interferometer 1, a beam expander collimation system 2, and a transmission mirror two-dimensional adjustment system 3 , Mirror four-dimensional adjustment system 4, 3 sets of planar optical eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com