A multi-tube gaseous fuel blender with single inclined tube outlet

A gaseous fuel and blender technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of incomplete premixed combustion, high local equivalent ratio, uneven temperature distribution, etc., to reduce emissions, exposure The effect of increasing the area and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

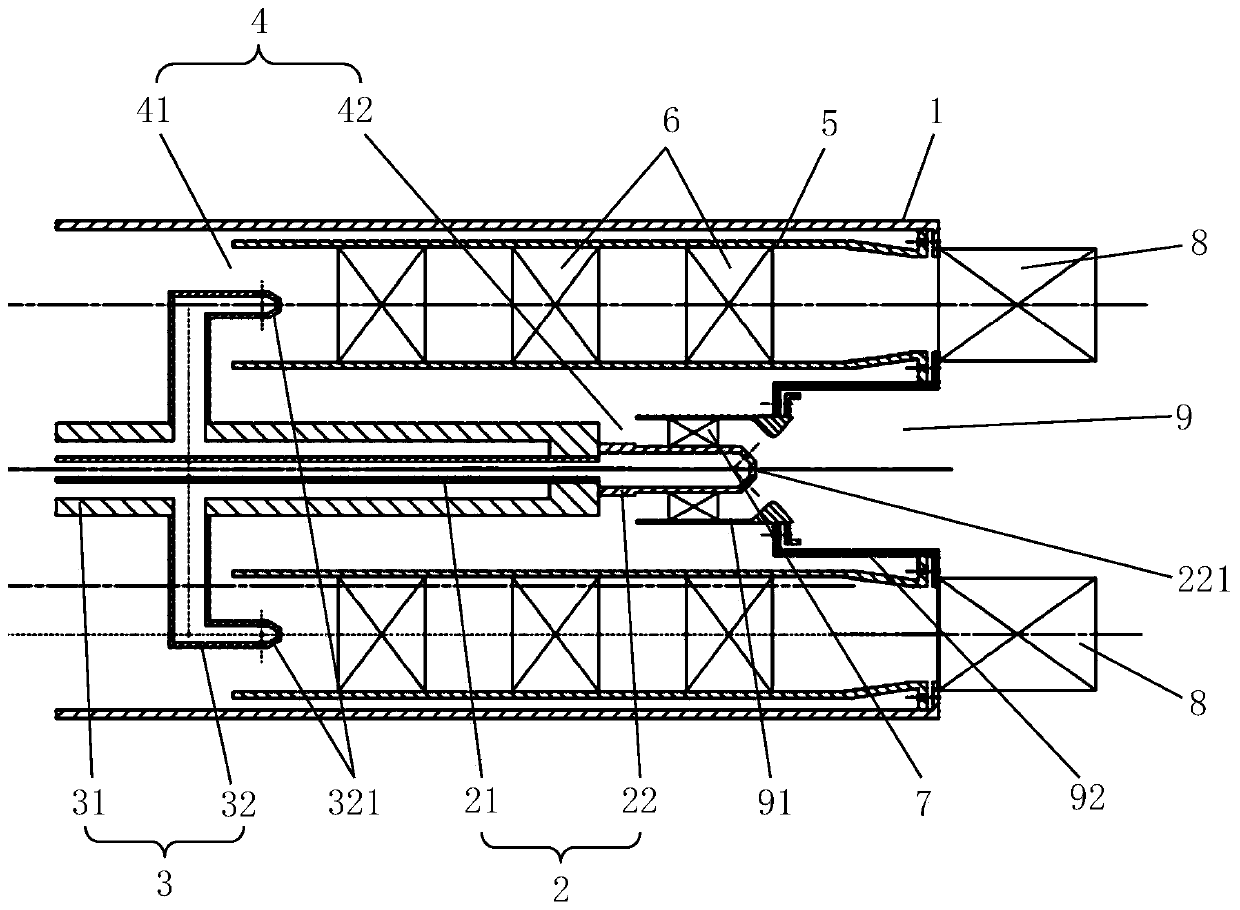

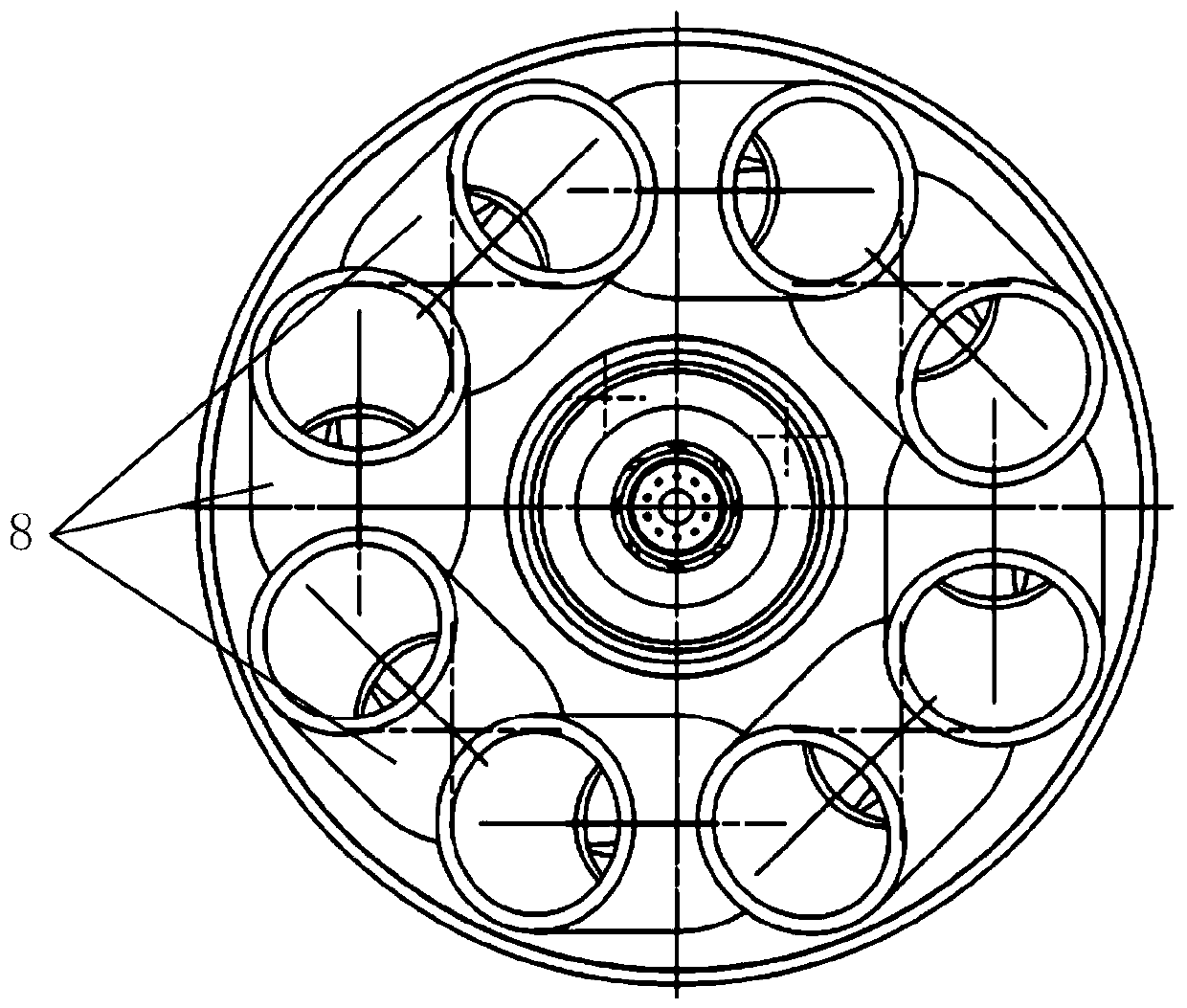

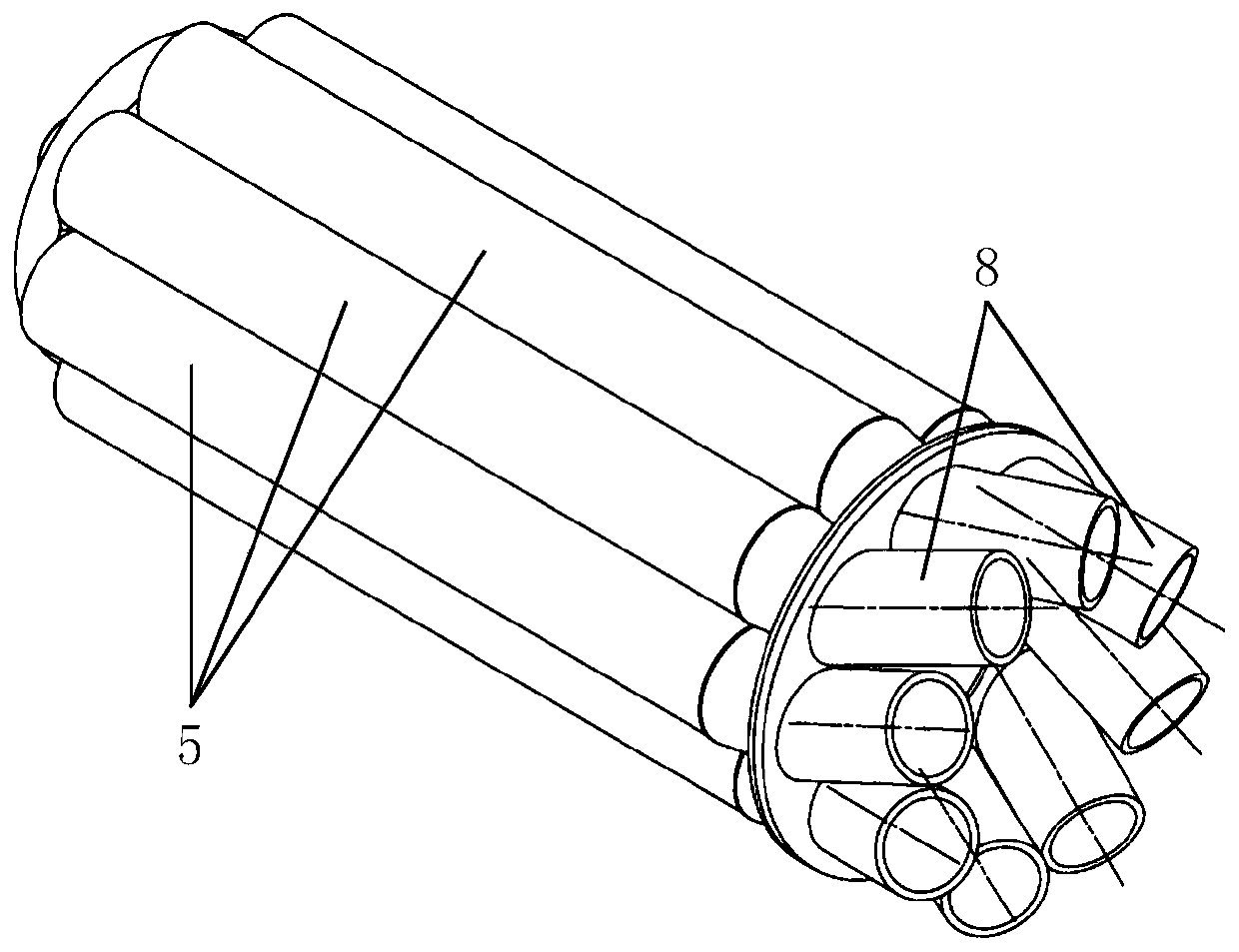

[0031] Such as figure 1 , figure 2 and image 3 As shown, a multi-tube gaseous fuel blender with a single inclined tube outlet provided by an embodiment of the present invention includes a tubular casing 1, and a central fuel passage 2, The peripheral fuel passage 3 and the annular air passage 4, wherein the peripheral fuel passage 3 is sleeved on the outer periphery of the central fuel passage 2, and the central fuel passage 2 includes a central fuel delivery pipe 21 arranged along the central axis of the housing, and connected to the central fuel passage. The central fuel nozzle 22 at the end of the delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com