Spherical external combination heat power machine

A heat power machine, spherical technology, applied in the field of spherical external combustion heat power machine, can solve the problems of complex interlocking mode, cumbersome device structure, low output power, etc., to facilitate the development and utilization, remove the transmission device and components, and output power Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

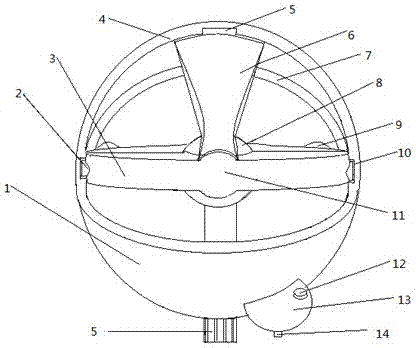

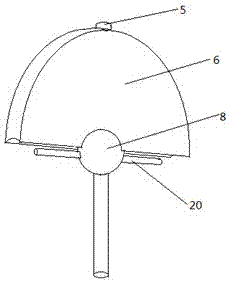

[0021] Such as Figure 7 As shown in the figure, the interior of the spherical cylinder (1) is divided into three areas, abc, by the circular rotor (3) and the semicircular partition (6). The plates are separated, and the c space is a through space in the lower part of the rotor (3). When the orbital ring connecting shaft (2) on the rotor (3) is at the highest point and the lowest point of the orbital ring groove (20), the space a between the rotor (3) and the partition (6) is airtight and the space is the smallest, and the cylinder The air vent (9) in the middle of the body (1) is open, and spaces b and c are both open. At this time, the gas in space a is heated, the gas expands, and the expanded gas pushes the rotor (3) along the rotating track of the track ring 7 to Move down and rotate, and drive the partition (6) to rotate together, the space a becomes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com