A construction fence for civil engineering

A technology of civil engineering and fencing, applied in the direction of buildings, fences, building types, etc., can solve problems such as construction waste, unstable bottom, troublesome disassembly, etc., and achieve the effects of enhanced wind resistance, easy assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

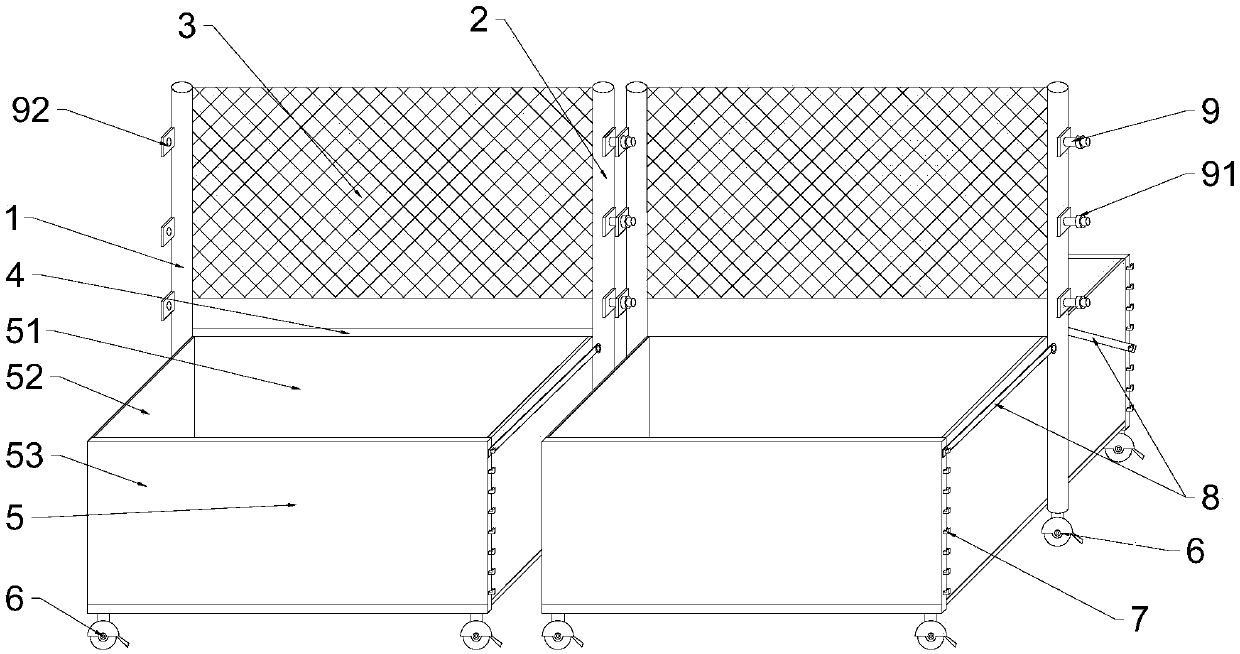

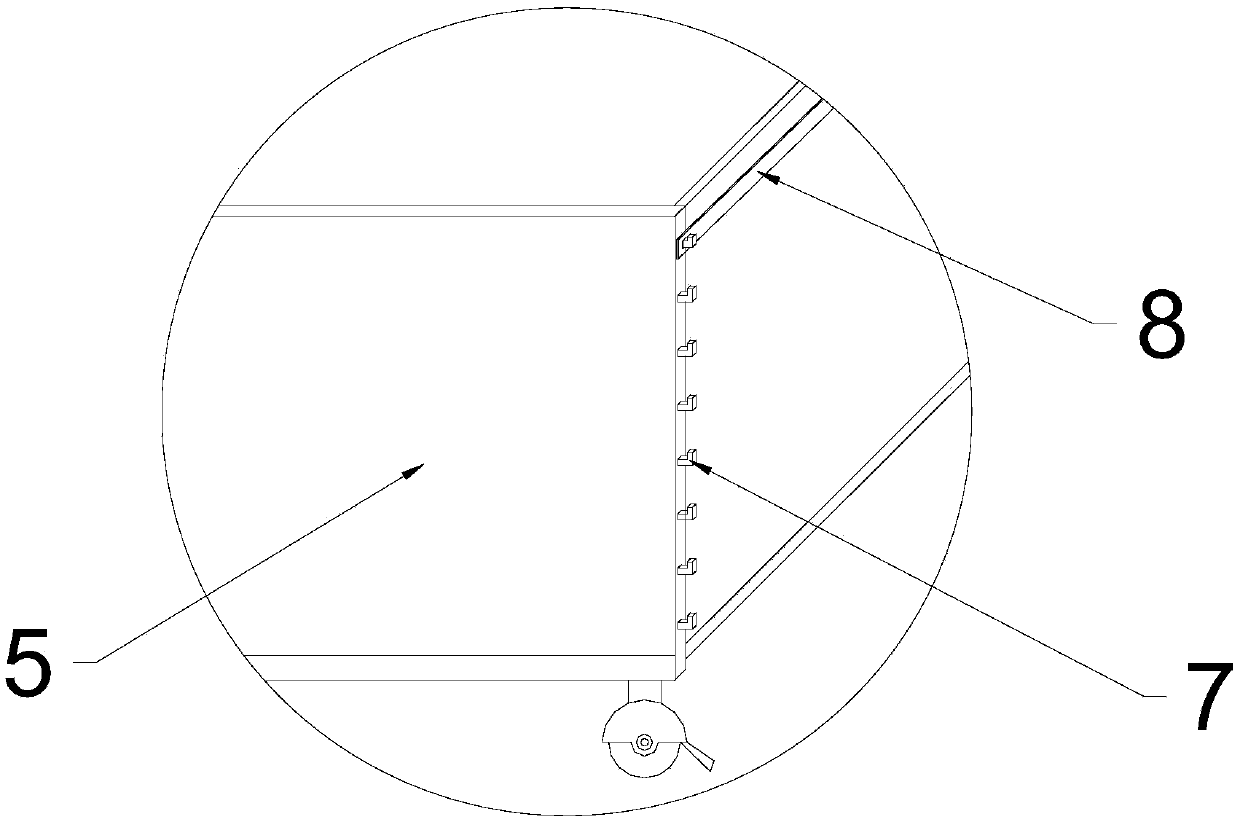

[0022] Such as figure 1 , figure 2 , image 3 The shown construction fence for civil engineering includes a fence main body and a box body 5. The fence main body includes a first column 1, a second column 2, a shielding plate 3, and a transverse support rod 4. The first column 1 and the A plurality of transverse support rods 4 are arranged between the second uprights 2, and a shading plate 3 is arranged between the first upright 1 and the second upright 2, and the shading plate 3 is located between the first upright 1 and the second upright 2. Partially above, the first column 1 is provided with a connecting block 92, the second column 2 is provided with a connecting bolt 9, and the connecting bolt 9 is provided with a fastening nut 91, and the connecting bolt 9 can pass through the connection on the connecting block 92. hole, then fix with fastening nut 91, two described fence main bodies are connected together, described fence main body both sides are provided with box bo...

Embodiment 2

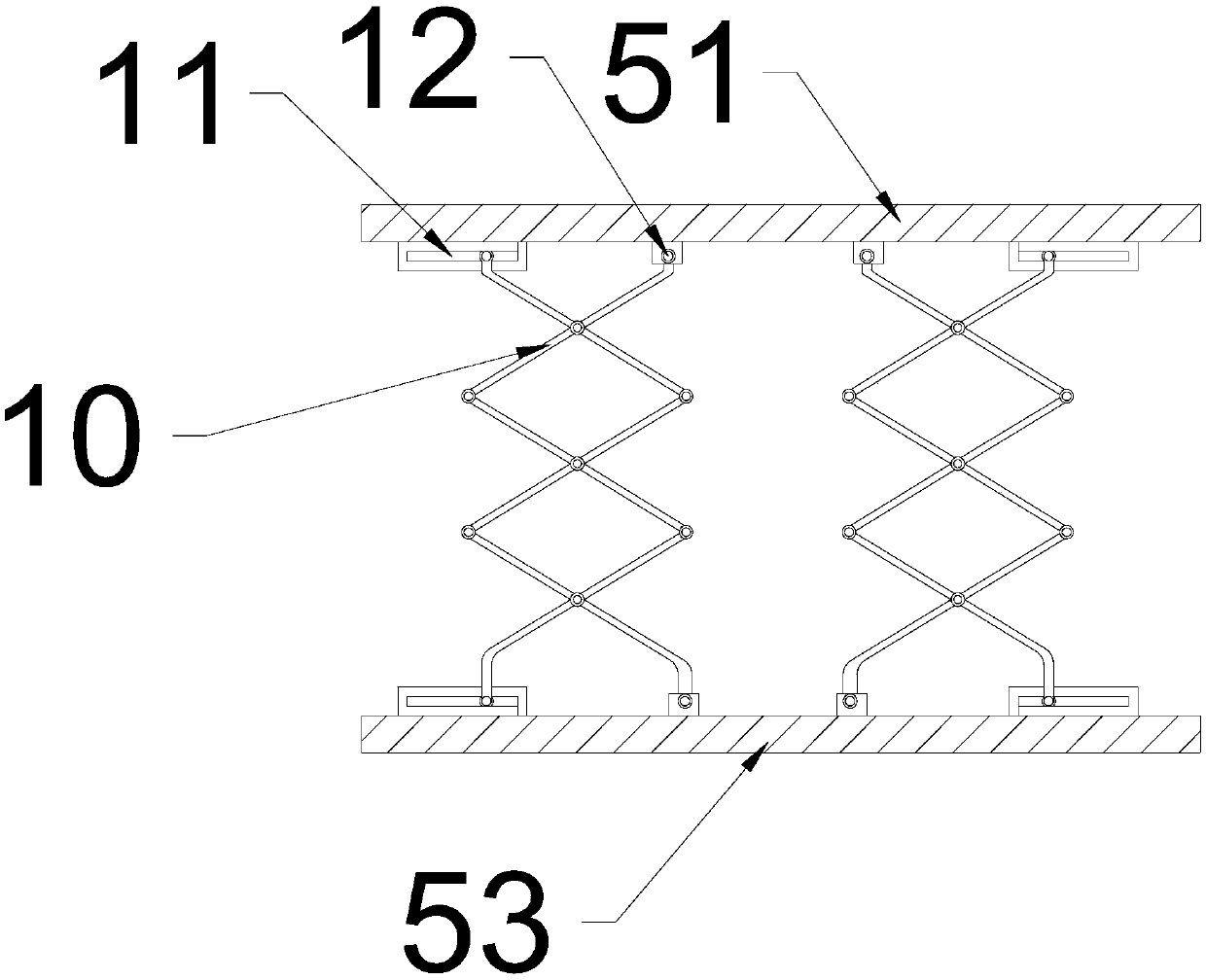

[0031] Specifically, the telescopic assembly includes guide rails 14, a plurality of supporting plates 13, the supporting plates 13 are parallel to the connecting plate 51, between the supporting plate 13 and the connecting plate 51, between the supporting plate 13 and the supporting plate 53, The adjacent two supporting plates 13 are all equipped with a shearing assembly, and the shearing assembly is provided with a pair of supporting rods 10 crossing each other, and the assembly method is as follows: Figure 5 As shown, as the assembly mode of the shearing assembly between the supporting plate 13 and the connecting plate 51: one end of one of the support rods 10 is provided with a guide slider, and the guide slider is assembled into the guide track 14 on the connecting plate 51, and the support rod The other end of 10 is hinged on the pallet 13 through a hinge, and one end of the other support rod 10 is provided with a guide slider, which is assembled into the guide track on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com