Horizontal safety braking device for gear and rack driven lifting equipment

A technology of lifting equipment and safety braking, which is applied in elevators, hoisting devices, transportation and packaging, etc., and can solve problems such as performance reduction, failure, and inability to guarantee reliable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

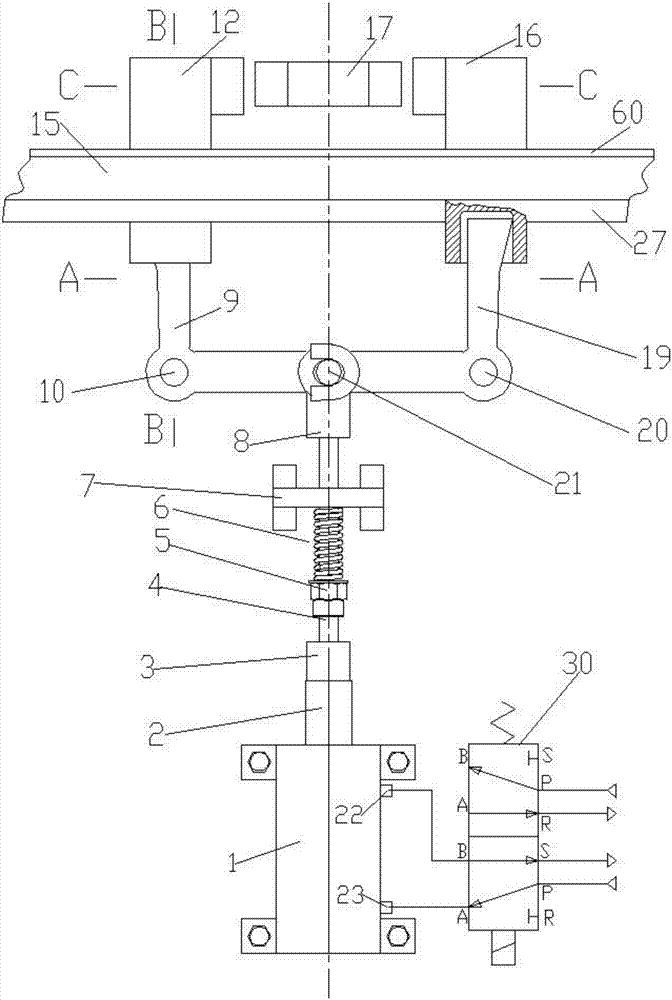

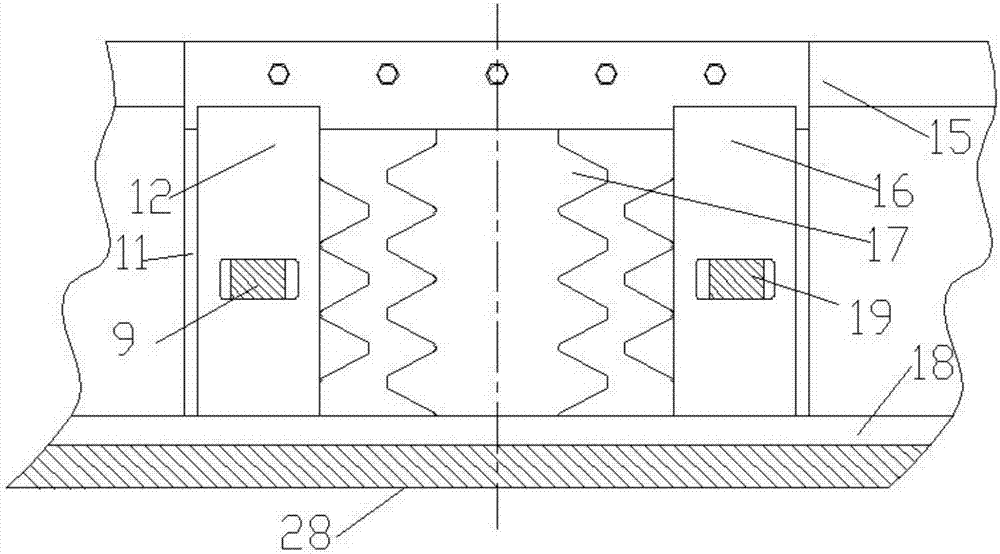

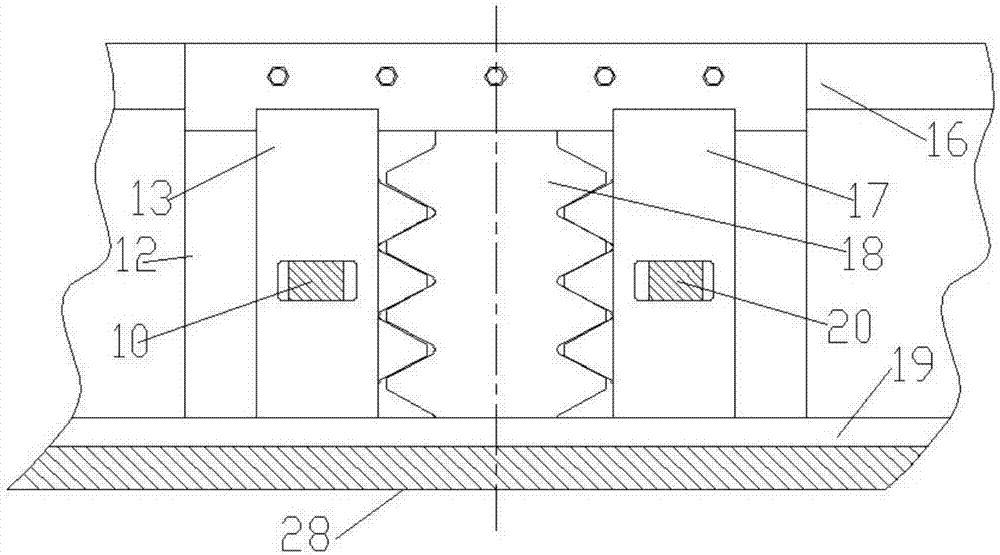

[0021] Example 1, Figure 9 It is a schematic diagram of Embodiment 1, and the drawing shows the appearance of the side of the lifting equipment. The horizontal safety brake device is installed on the top of the rack-and-pinion lifting equipment, temporarily in a free position, and the lifting equipment is ready to run or is running Case, Figure 10 It is a schematic diagram of the situation that the horizontal safety braking device of embodiment 1 brakes the lifting equipment, (the front figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 The left and right mentioned are viewed from the inside of the lifting device to the side of the lifting device. Figure 9 , Figure 10 It is viewed from the outside to the side of the lifting equipment, so the left and right directions are just in reverse). Figure 1-8 , Figure 11As shown, and [0005] section, [0006] section, [0007] section, Embodiment 1 controls the compressed air or hydraulic oil through the solenoid valve to ...

Embodiment 2

[0022] Example 2, Figure 9 , Figure 10 It is also a schematic diagram of Embodiment 2, which shows an elevator equipped with a horizontal safety braking device for rack and pinion lifting equipment according to the present invention, and its appearance is the same as Figure 7 , Figure 8 , the internal structure of the horizontal safety brake device and its functions are described in Figure 1-8 , Figure 11 As shown, and described in [0005], [0006], and [0007], the working principle is the same as that described in [0021].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com