Printing machine bottom roller dedusting device

A dust removal device and printing machine technology, applied to printing machines, printing, general parts of printing machinery, etc., can solve the problems of high labor intensity, waste, and easy anti-sticking on the bottom roller of the embossing, so as to improve work efficiency, Efficient removal, the effect of ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

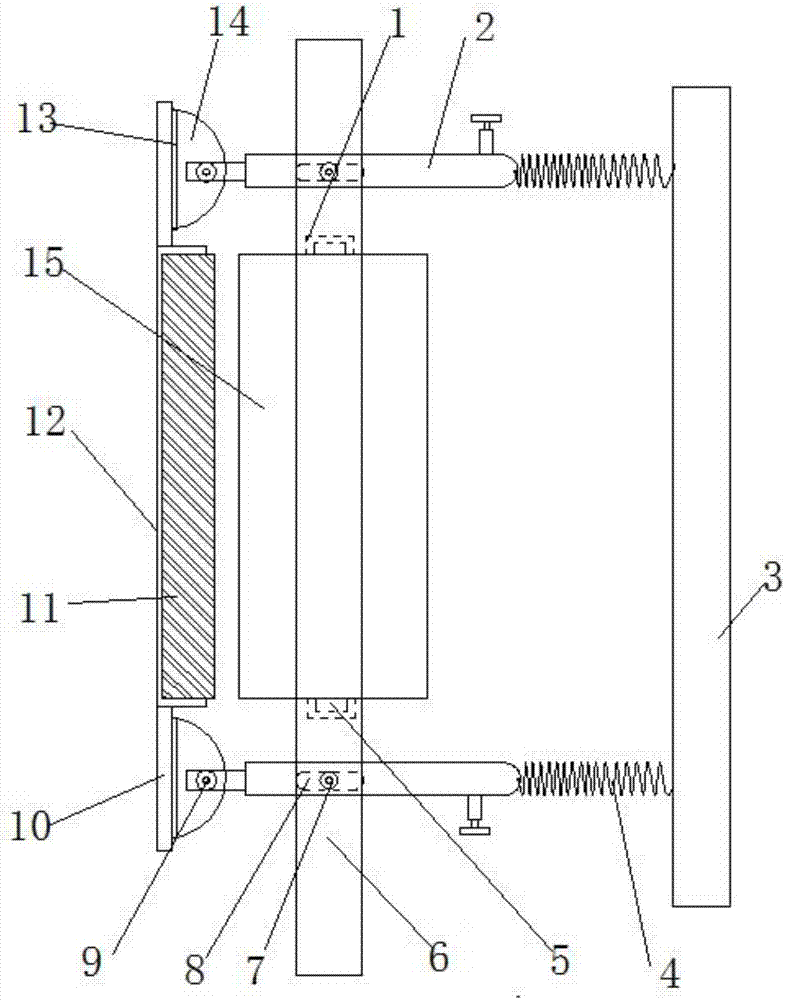

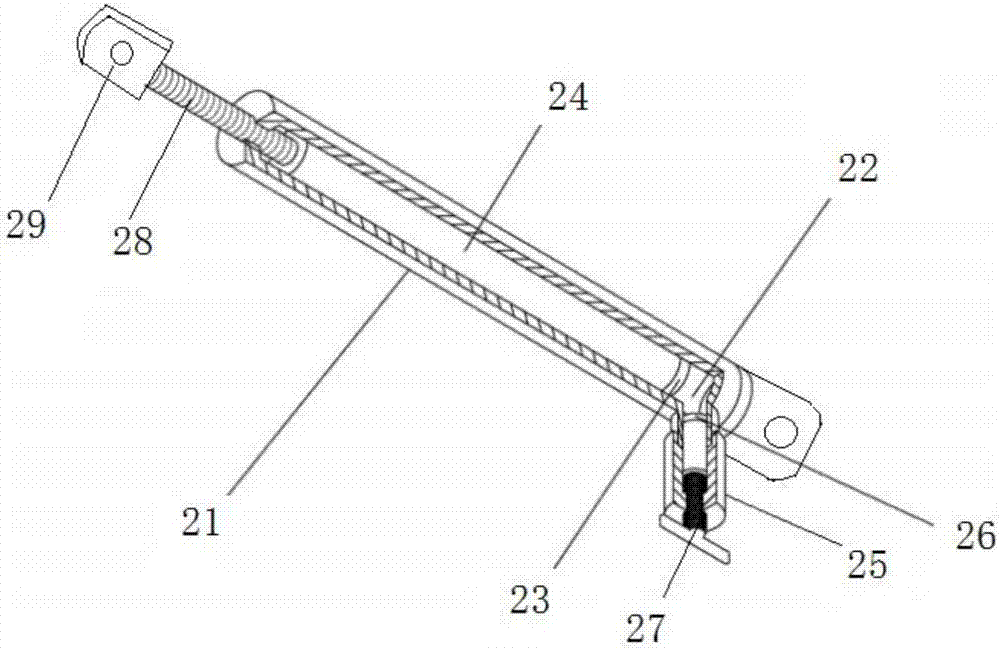

[0014] Such as figure 1 , figure 2 As shown, the dust removal device for the bottom roller of the printing machine includes: a bottom roller 15, the bottom roller 15 is installed on the bottom roller fixing bracket 1 through the bottom roller fixing shaft 5, and the bottom roller fixing bracket 1 is fixed on the bottom roller mounting frame 6, one side of the bottom roller 15 is provided with a dust removal sponge 11, the dust removal sponge 11 is soaked with 202 g of hydrogen-containing silicone oil, the dust removal sponge 11 is embedded in the dust removal sponge groove 12, and the two ends of the dust removal sponge groove 12 are provided with Dust removal trough fixed plate 10, adjustable support rod 2 is installed on the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com