Lower exposure type ceramic photocuring 3D printing equipment and manufacturing method thereof

A 3D printing, light curing technology, applied in the field of 3D printing, can solve the problems of small peeling force, affecting printing accuracy, uneven ceramic density, etc., to achieve the effect of smooth peeling, enhanced fluidity, and improved printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

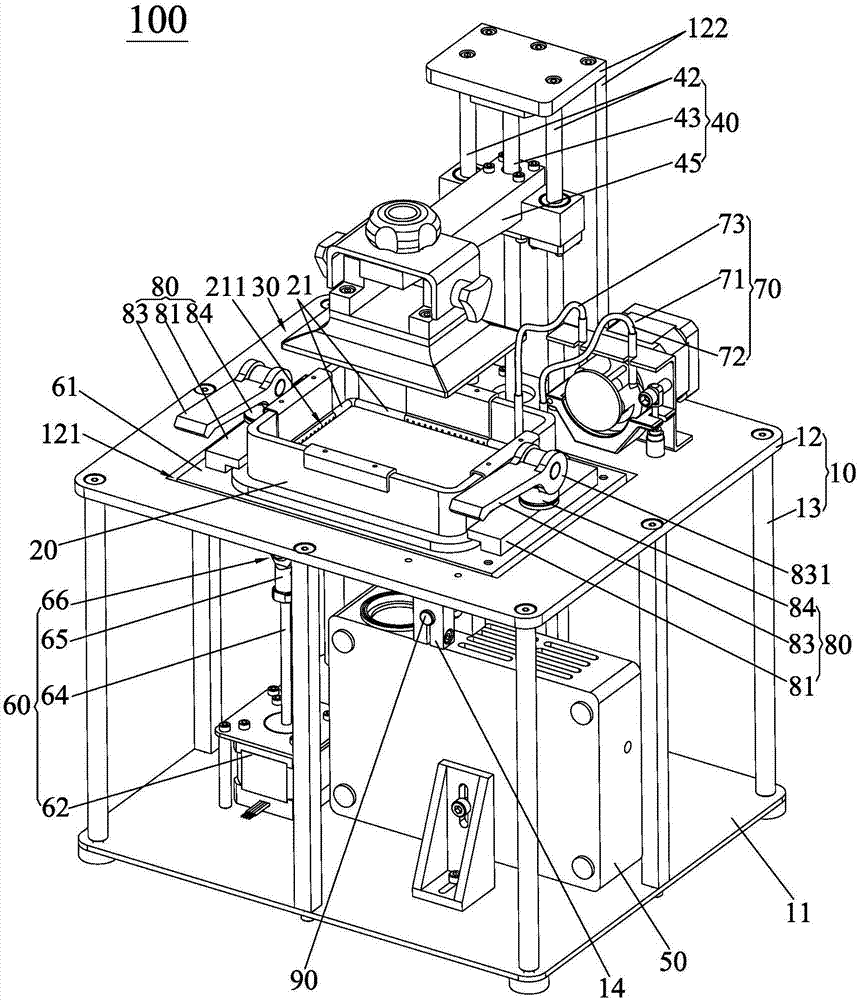

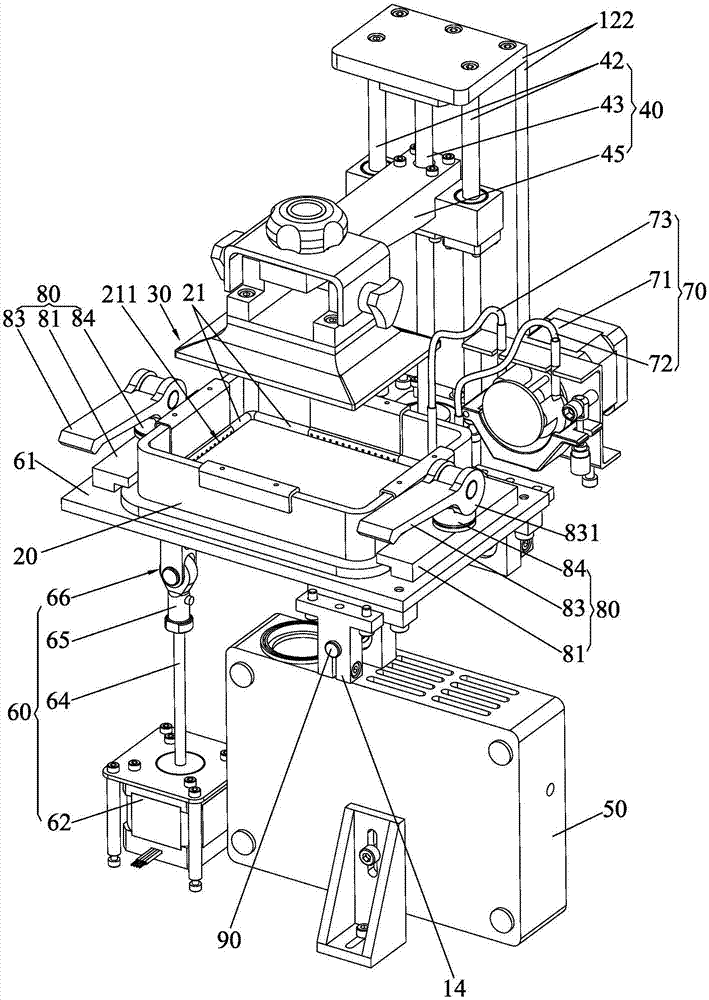

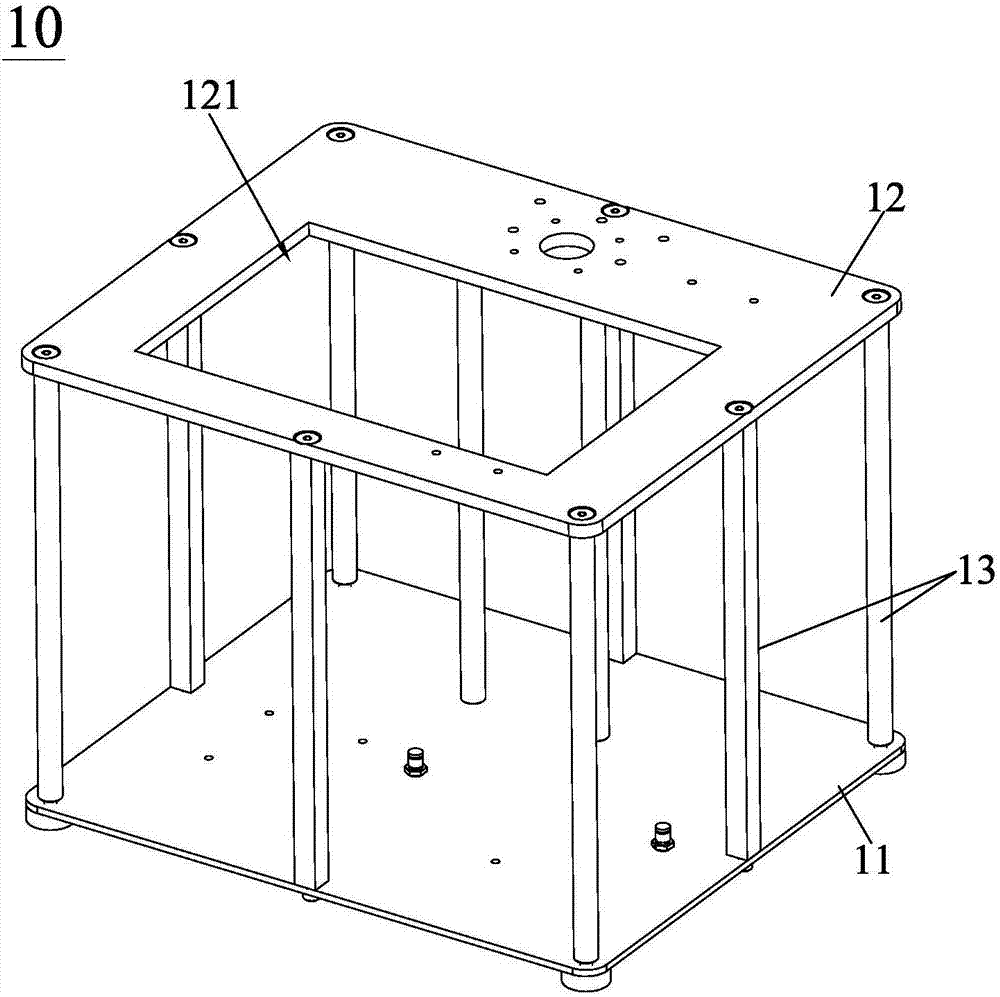

[0027] see figure 1 and figure 2 , the under-exposure ceramic light-curing 3D printing equipment 100 of the present invention is mainly used in the fields of mold making, medical equipment, cultural relic protection and architectural design, and is used to print a three-dimensional model from a light-curing liquid mixed with ceramic particles and photosensitive resin, so that The bottom-exposure ceramic light-curing 3D printing equipment 100 of the present invention can produce products such as orthopedics, dentistry and micro sensors, but not limited thereto. For example, in the proportion of the photocurable liquid, the content of ceramic particles is about 50%, but not limited thereto.

[0028] The bottom-exposure ceramic light-curing 3D printing equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com