Plane air floatation workbench based on optical feedback and control method

An optical feedback, workbench technology, applied in workbenches, manufacturing tools, etc., can solve the problems of high precision of support surface, increase platform production cost, increase friction resistance of mover, etc., to avoid magnetic hysteresis phenomenon, and to achieve reliable suspension. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

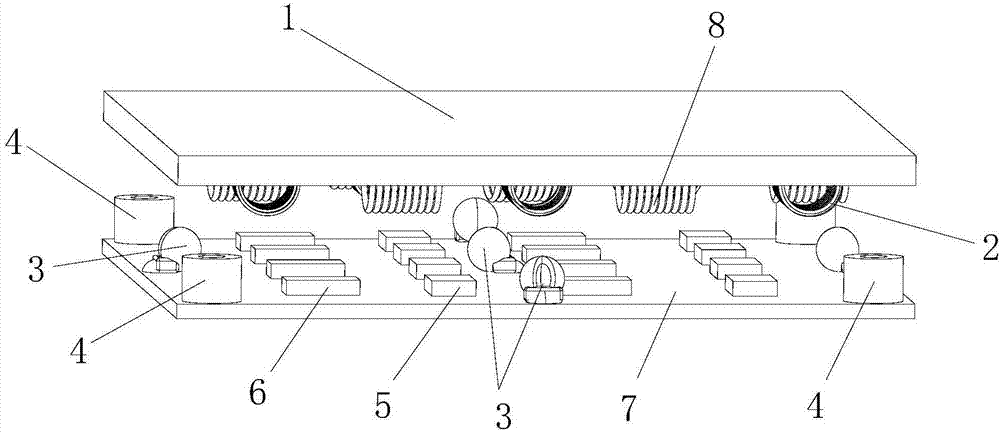

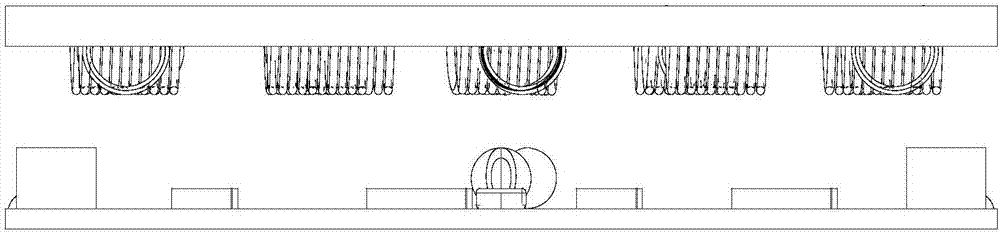

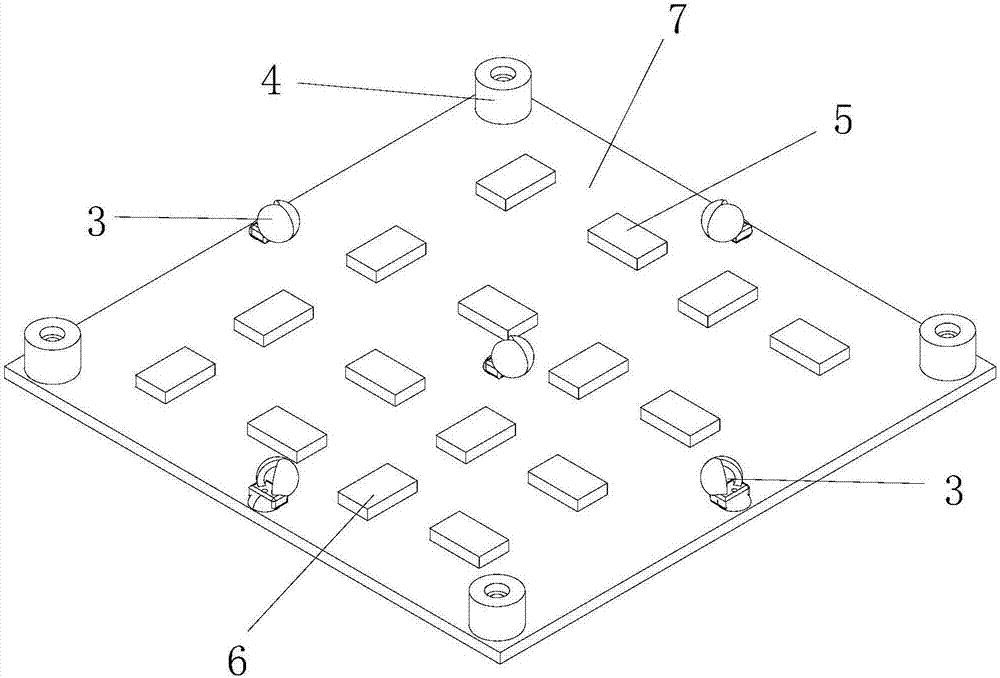

[0045] Such as figure 1 and figure 2 As shown, the invention discloses a planar air-floating workbench based on optical feedback, and the air-floating workbench is mainly used in high-speed, high-precision, and high-precision control occasions. The plane air flotation workbench mainly includes a lower panel 7, an upper panel 1, an electromagnetic drive unit for driving the upper panel 1, an air flotation unit for suspending the upper panel 1, an infrared sensor group 3 for positioning, and Control unit for guiding and positioning the movement of the upper panel 1 . The lower panel 7 is fixedly installed, the infrared sensor group 3 and the air flotation unit are installed on the lower panel 7 , and the driving unit is installed on the upper panel 1 . The control unit is respectively connected with the drive unit, the air flotation unit and the infrared sensor group 3. By controlling the air flotation unit, the upper panel 1 is suspended in the air, and by controlling the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com