Semi-automatic welding fixture for sheet welding

A semi-automatic welding and thin plate welding technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inflexible welding, unsightly weld seam, and damage to human tissue, etc., and achieve good fixing effect , Fixtures are low in cost, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

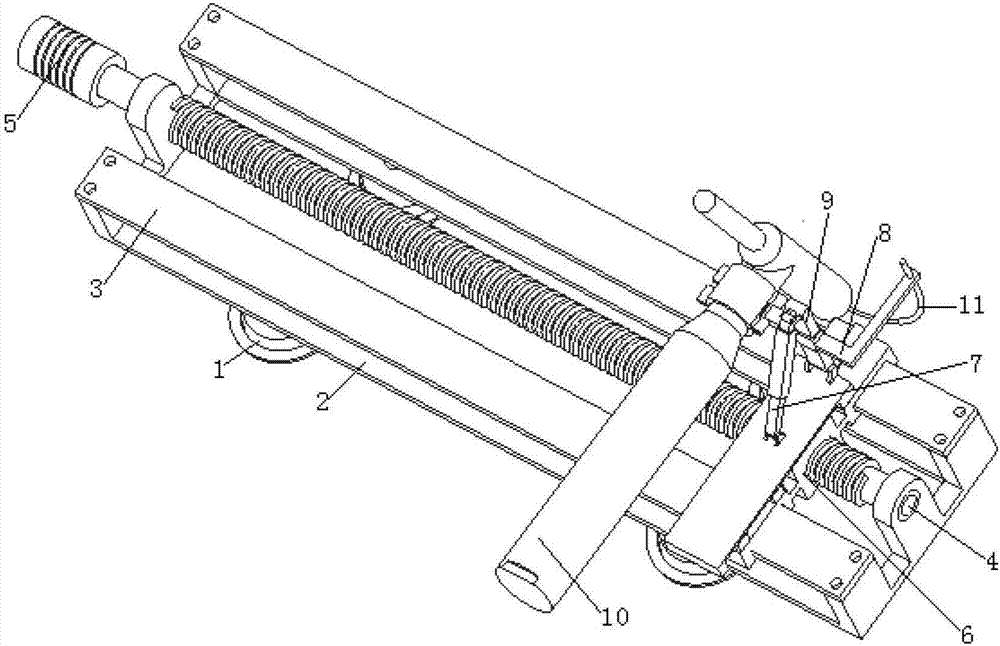

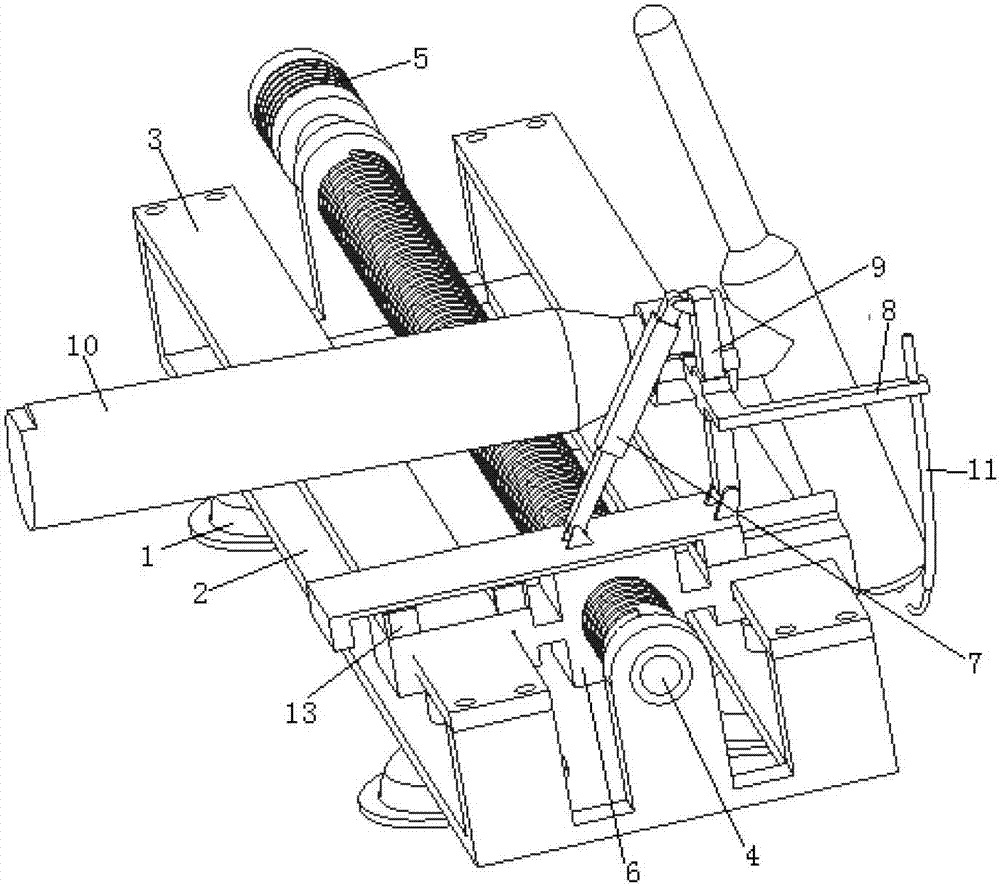

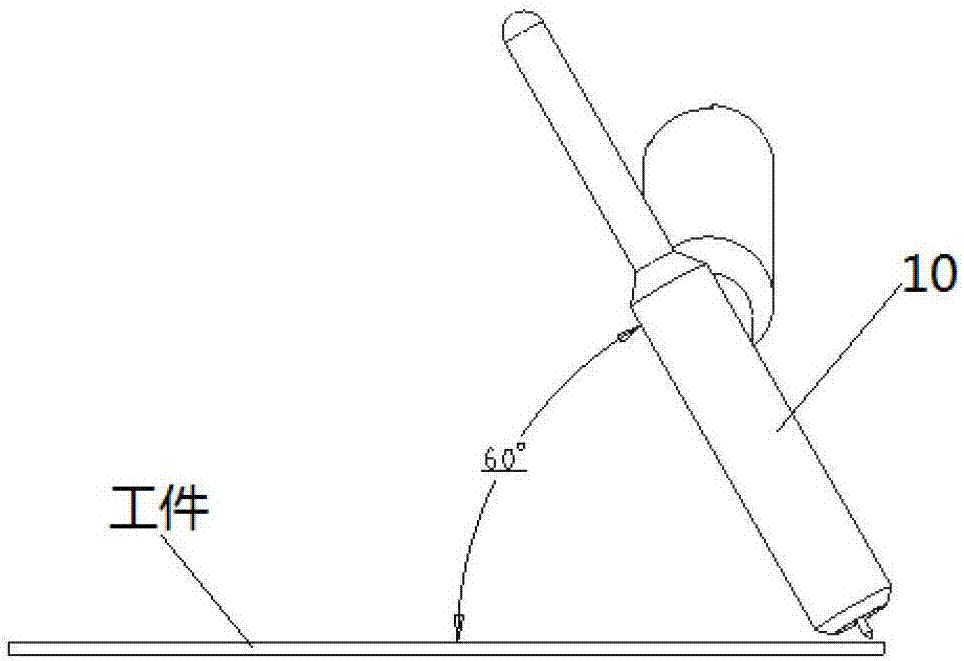

[0028] Such as figure 1 and figure 2 As shown, the present invention includes a fixture frame body 2, the top of the fixture frame body 2 is provided with a lead screw 4 and a slide rail 3 parallel to the axis of the lead screw 4, two slide rails 3 are arranged on the lead screw 4 respectively On both sides of the axial direction; the screw 4 is threaded with a nut slider 6, the end of the nut slider 6 is sleeved on the slide rail 3, and the nut slider 6 is driven by the screw 4 to slide along the slide rail 3; the nut slider A welding torch clamping device for fixing the welding torch is installed on the block 6, and the bottom of the fixture frame body 2 is provided with a fixing device fixed to the workpiece, and the fixing device is the fixture suction cup 1;

[0029] One end of the lead screw 4 is connected to the output end of the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com