Improved glass coating wiping equipment

An improved glass-feeding technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of poor overall versatility, poor wiping effect, high cost, etc., to ensure the cleanliness of wiping , Reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

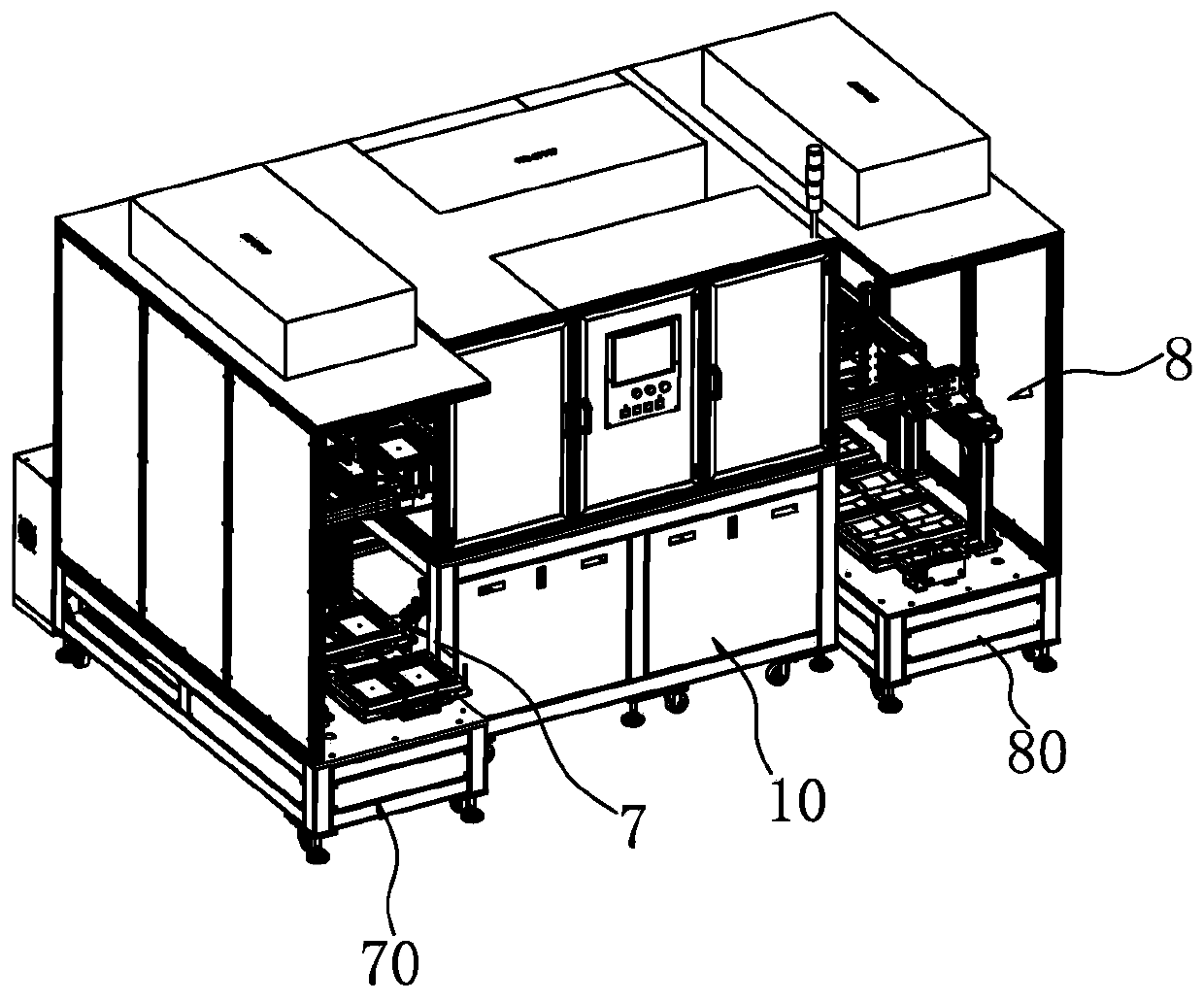

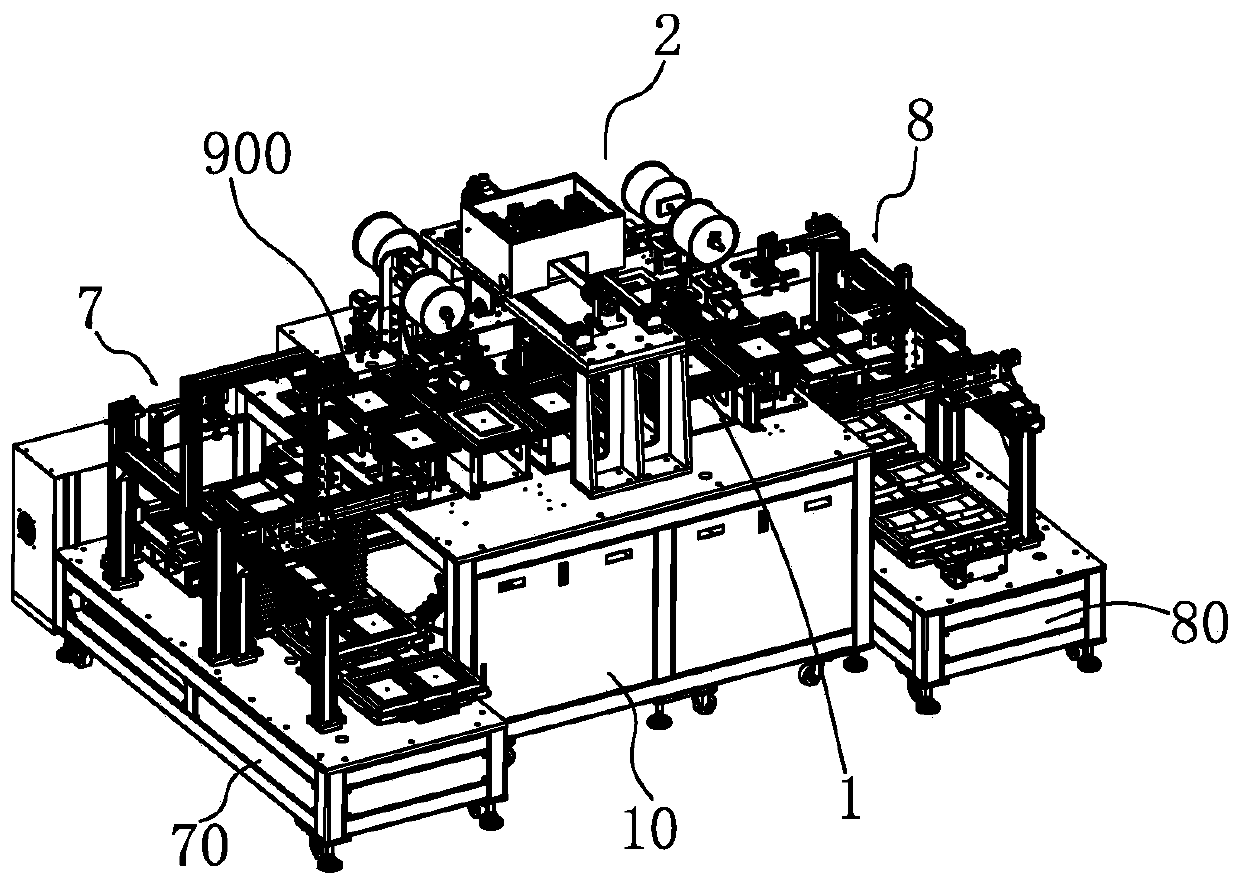

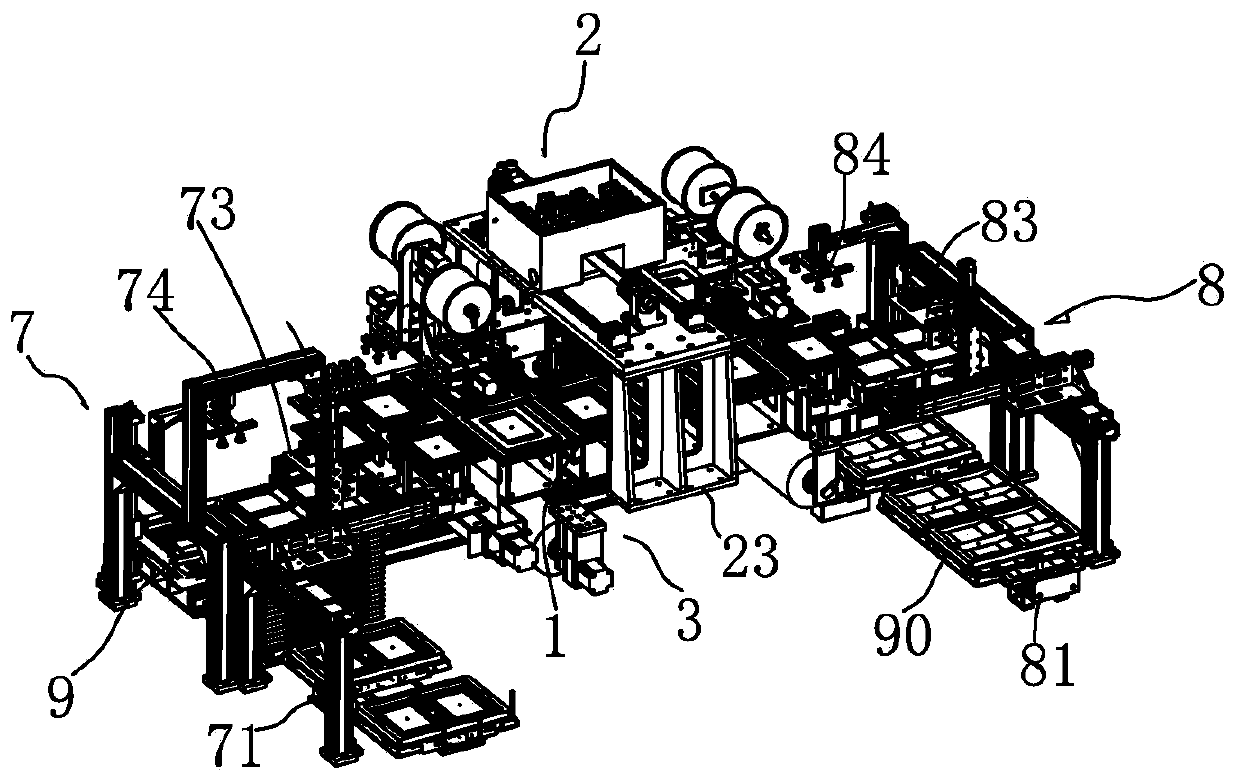

[0032] Figure 1~4 As shown, the improved glass coating wiping equipment includes: a feeding device 7, a retrieving device 8 and a wiping device located between them. A cover is arranged above the wiping device, the feeding device 7 and the reclaiming device 8 to ensure that the entire wiping device works in a relatively clean ring.

[0033] When the present invention works, the glass pieces 900 to be wiped are placed in the tray 90, and then the stacked trays 90 are placed on the feeding device 7, and the glass pieces 900 are transported to the wiping device by the feeding device 7 for wiping operation. Simultaneously, empty trays 90 are transported from the infeed device 7 to the reclaimer 8 via the conveyor belt 9 . After the wiping is completed, the wiped glass pieces 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com