Heterojunction photocatalyst and preparation method thereof

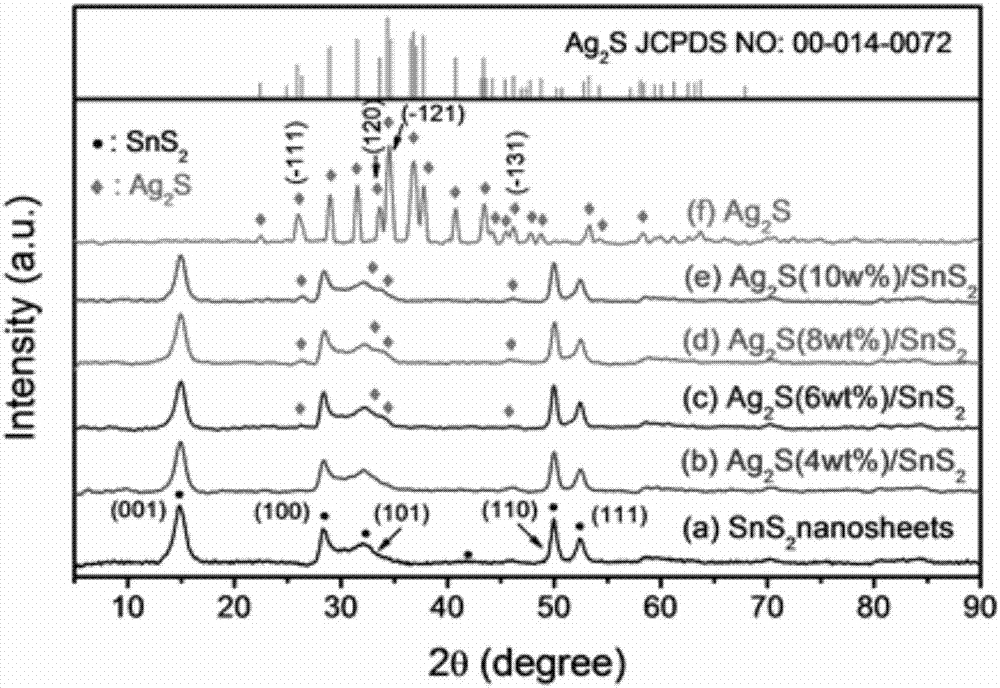

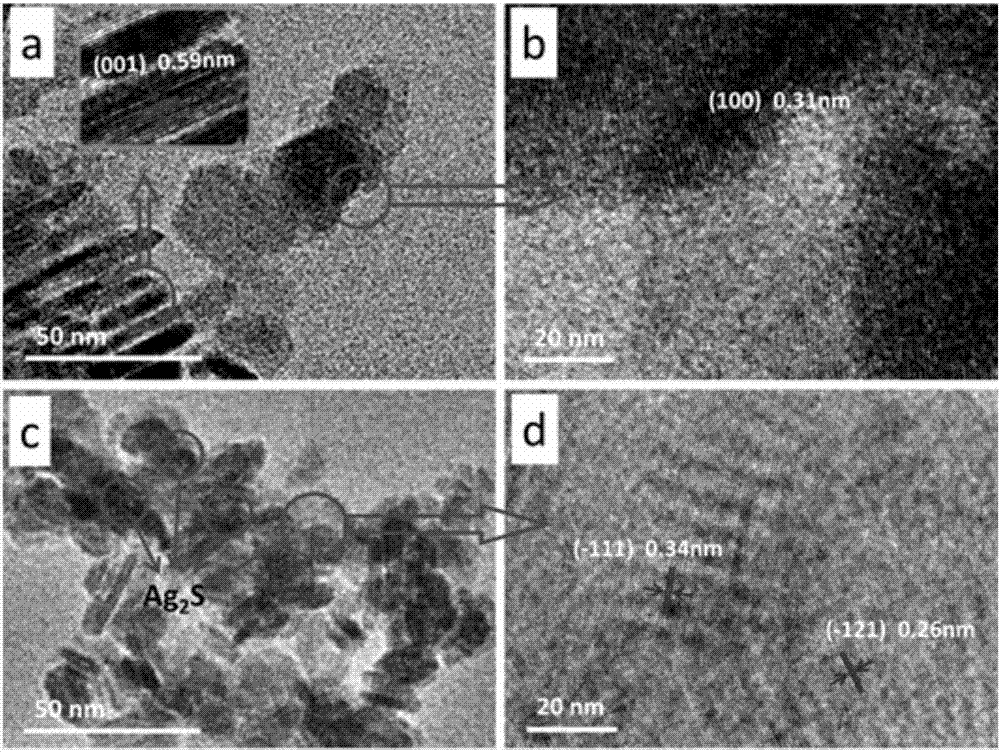

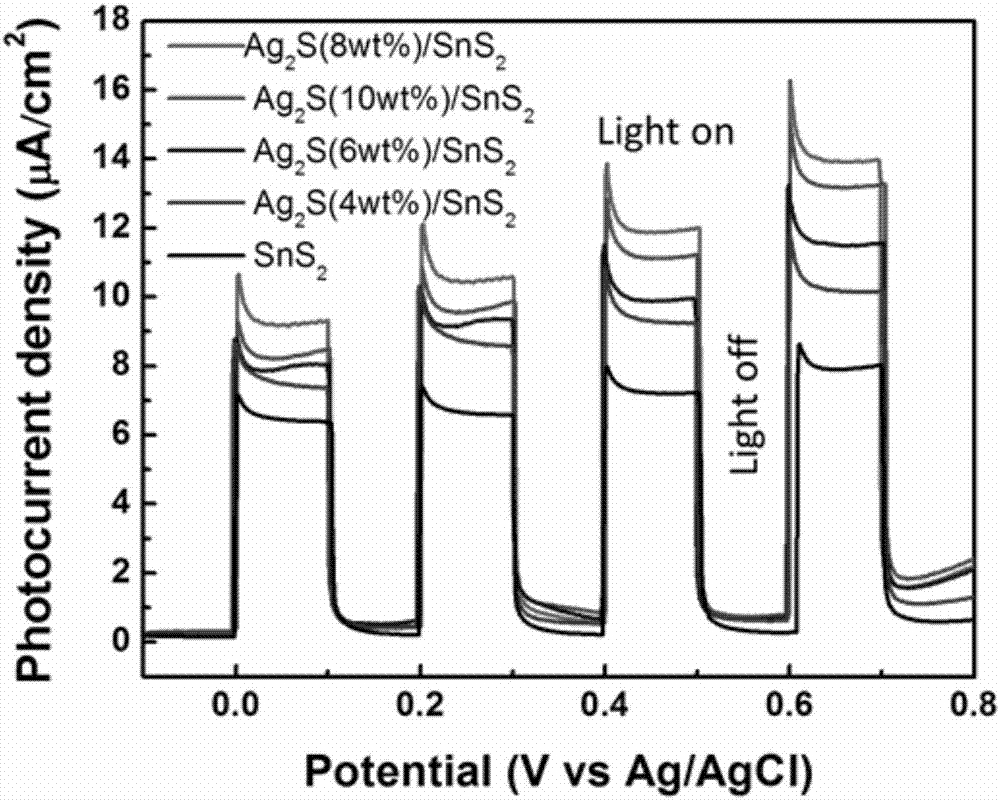

A photocatalyst and heterojunction technology, which is applied in the field of photoelectrochemical materials and photocatalysis, can solve the problems of easy decomposition, difficulty in repeated collection of SnS2, and insufficient photocatalytic activity, and achieve excellent light absorption performance, strong stability, and strong The effect of the photoelectrochemical response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 4mmol of tin tetrachloride and 8mmol of thioacetamide into 40mL of distilled water, mix well and add into a PTFE reactor with a volume of 50mL, react at 180°C for 24 hours, and cool naturally After reaching room temperature, they were washed by centrifugation with distilled water and absolute ethanol for 2 to 3 times, and vacuum-dried at 60°C to obtain SnS 2 Nanosheets;

[0018] (2) 0.5g SnS synthesized in step (1) 2 Put nanosheets into a 500mL beaker, measure 300mL of distilled water into the beaker, and ultrasonically disperse for 3 hours to form a uniform yellow dispersion; then measure 0.01mol / L Na 2 Add 3mL of S solution into the beaker, stir for 10 minutes, then measure 4mL of 0.1mol / L silver nitrate solution, slowly add it into the beaker drop by drop, finish adding dropwise in 30 minutes, keep stirring for 3 hours, and finally keep the temperature at 30°C for 2 hours, a brown precipitate was obtained, which was Ag 2 S / SnS 2 heterojunction photocataly...

Embodiment 2

[0021] (1) Add 2mmol of tin tetrachloride and 4mmol of sodium sulfide into 40mL of distilled water, mix well and add into a 50mL polytetrafluoroethylene reactor, react at 180°C for 24 hours, and cool to room temperature naturally Afterwards, they were centrifuged and washed 2 to 3 times with distilled water and absolute ethanol respectively, and vacuum-dried at 60°C to obtain SnS 2 Nanosheets;

[0022] (2) 0.5g SnS synthesized in step (1) 2 Put nanosheets into a 500mL beaker, measure 300mL of distilled water into the beaker, and ultrasonically disperse for 3 hours to form a uniform yellow dispersion; then measure 0.01mol / L Na 2 Add 3 mL of S solution into the beaker, stir for 10 minutes, then measure 1 mL of 0.1 mol / L silver acetate solution, slowly add it into the beaker drop by drop, finish adding in 30 minutes, keep stirring for 3 hours, and finally keep the temperature at 30°C for 2 hours, a brown precipitate was obtained, which was Ag 2 S / SnS 2 heterojunction photocat...

Embodiment 3

[0024] (1) Add 10mmol of tin tetrachloride and 20mmol of thiourea into 40mL of distilled water, mix well and add into a polytetrafluoroethylene reactor with a volume of 50mL, react at 180°C for 24 hours, and cool to room temperature naturally Afterwards, they were centrifuged and washed 2 to 3 times with distilled water and absolute ethanol respectively, and vacuum-dried at 60°C to obtain SnS 2 Nanosheets;

[0025] (2) 0.5g SnS synthesized in step (1) 2 Put nanosheets into a 500mL beaker, measure 300mL of distilled water into the beaker, and ultrasonically disperse for 3 hours to form a uniform yellow dispersion; then measure 0.01mol / L Na 2 Add 3 mL of S solution into the beaker, stir for 10 minutes, then measure 4 mL of 0.1 mol / L silver benzoate solution, slowly add it to the beaker drop by drop, finish adding in 30 minutes, still stir for 3 hours, and finally 30 ℃ Keep the temperature for 2 hours to get a brown precipitate, which is Ag 2 S / SnS 2 heterojunction photocatal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com