Preparation method for graphene quantum dot/SnS2 nano-sheet composite photocatalyst

A technology of graphene quantum dots and composite light, applied in the field of photoelectrochemical materials and photocatalysis, can solve the problems of easy decomposition, insufficient photocatalytic activity, difficulty in repeated collection of SnS2, etc., and achieve excellent light absorption performance, strong photoelectrochemical properties, etc. Responsiveness, the effect of large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

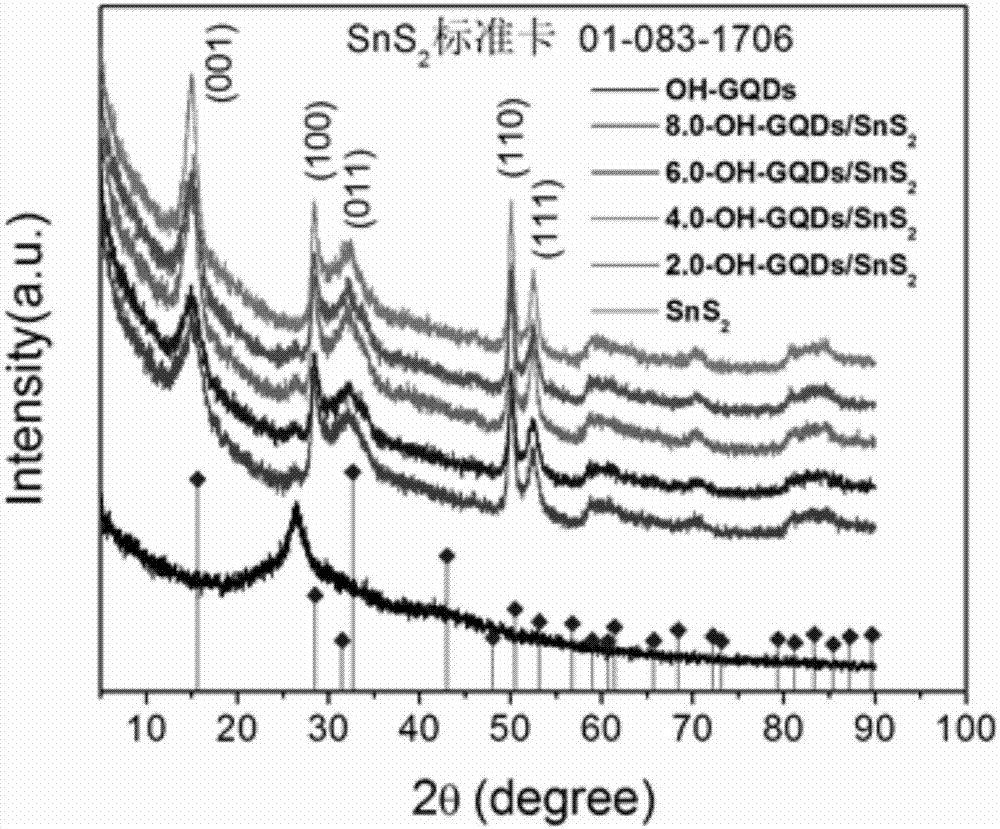

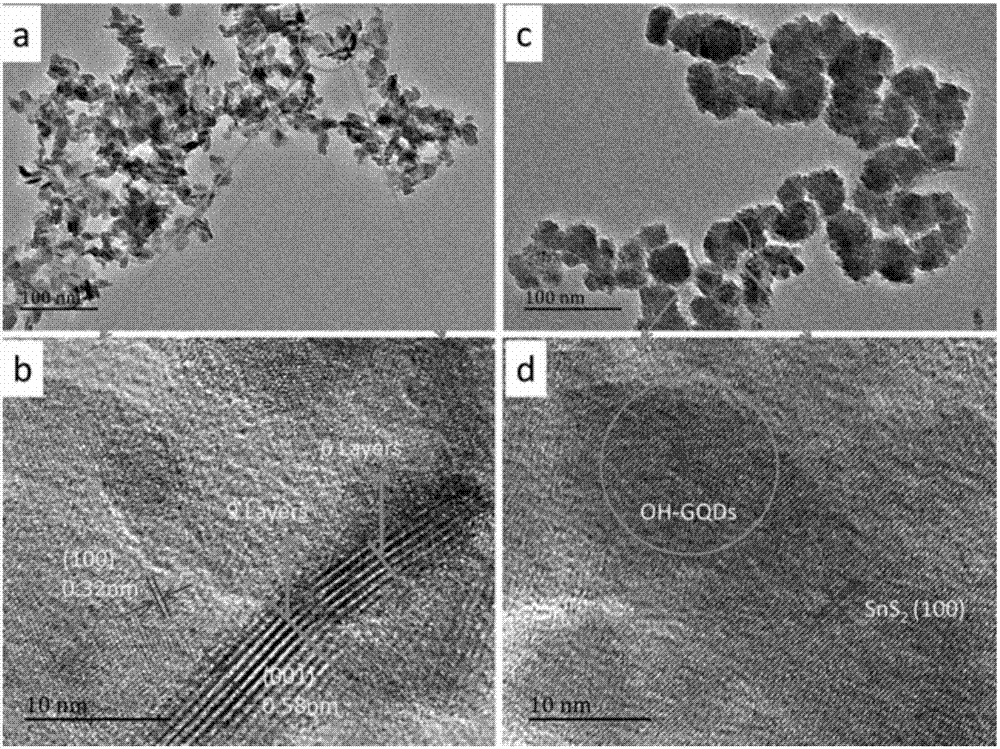

[0017] A simple one-step hydrothermal method is adopted: measure 2ml of graphene quantum dots with a concentration of 2mg / ml and add them to 40°C distilled water, weigh 4.4mmol of thioacetamide and 2mmol of tin tetrachloride, and put them together into The aqueous solution of quantum dots was stirred for 30 minutes, then put into a reaction kettle, and heated at 160° C. for 8 hours. Take out the reaction kettle and cool it down to room temperature, then centrifuge the solution to remove unreacted substances, obtain a precipitate and dry it in vacuum for 6 hours to obtain the product.

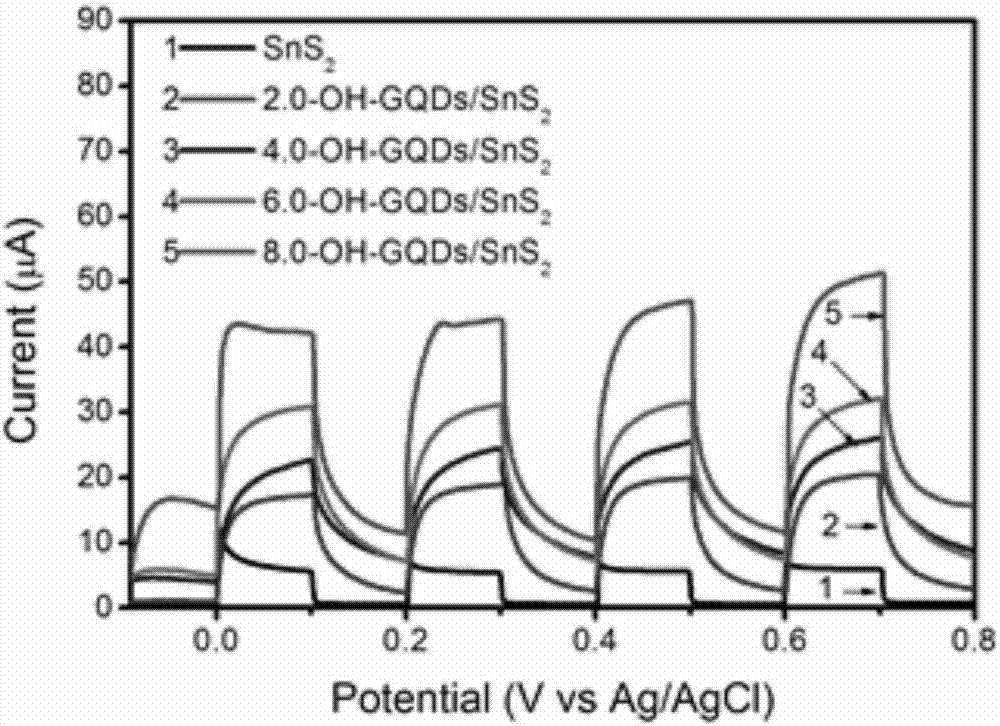

[0018] As-prepared SnS 2 Thin nanosheet dispersion liquid, make photoelectrode on ITO surface by spin-coating method, prepare electrode as working electrode (area is 1cm 2 ), the auxiliary electrode is a platinum electrode, and the saturated calomel electrode (SCE) is used as a reference electrode, 0.5mol / LNa 2 SO 4 In order to support the electrolyte solution, the photoelectrochemical perfor...

Embodiment 2

[0021] (1) Measure 8ml of graphene quantum dots with a concentration of 2mg / ml and add them to 40°C distilled water, weigh 8.8mmol thiourea and 4mmol tin tetrachloride, put them into the aqueous solution containing hydroxyl-graphene quantum dots and stir for 30 Minutes later, put it into a reaction kettle and heat at 120°C for 24 hours. Take out the reaction kettle and cool it down to room temperature, then centrifuge the solution to remove unreacted substances, obtain a precipitate and dry it in vacuum for 6 hours to obtain the product.

[0022] (2) Synthetic GQDs / SnS 2 The photocurrent of the heterojunction is SnS 2 3 times the photocurrent. It takes 45 minutes to degrade methyl orange to reach more than 99%.

Embodiment 3

[0024] (1) Measure 2ml of graphene quantum dots with a concentration of 2mg / ml and add them to 40°C distilled water, weigh 2.2mmol sodium sulfide and 1mmol tin tetrachloride, put them into the aqueous solution containing amino-graphene quantum dots and stir for 30 Minutes later, put it into a reaction kettle and heat at 160°C for 24 hours. Take out the reaction kettle and cool it down to room temperature, then centrifuge the solution to remove unreacted substances, obtain a precipitate and dry it in vacuum for 6 hours to obtain the product.

[0025] (2) Synthetic GQDs / SnS 2 The photocurrent of the heterojunction is SnS 2 4 times the photocurrent. It takes 35 minutes to degrade methyl orange to more than 99%.

[0026] The purity of the chemical reagents described in the above examples is chemically pure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com