An Optimal Control Method for Compatible Workpiece Family Considering Look-ahead Distance

A technology of optimized control and look-ahead distance, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of less consideration of future workpiece arrival information, inability to adjust the scheduling plan in time, and insufficient productivity, so as to avoid The effect of misprocessing or miswaiting, balancing processing and waiting process, and inventory extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

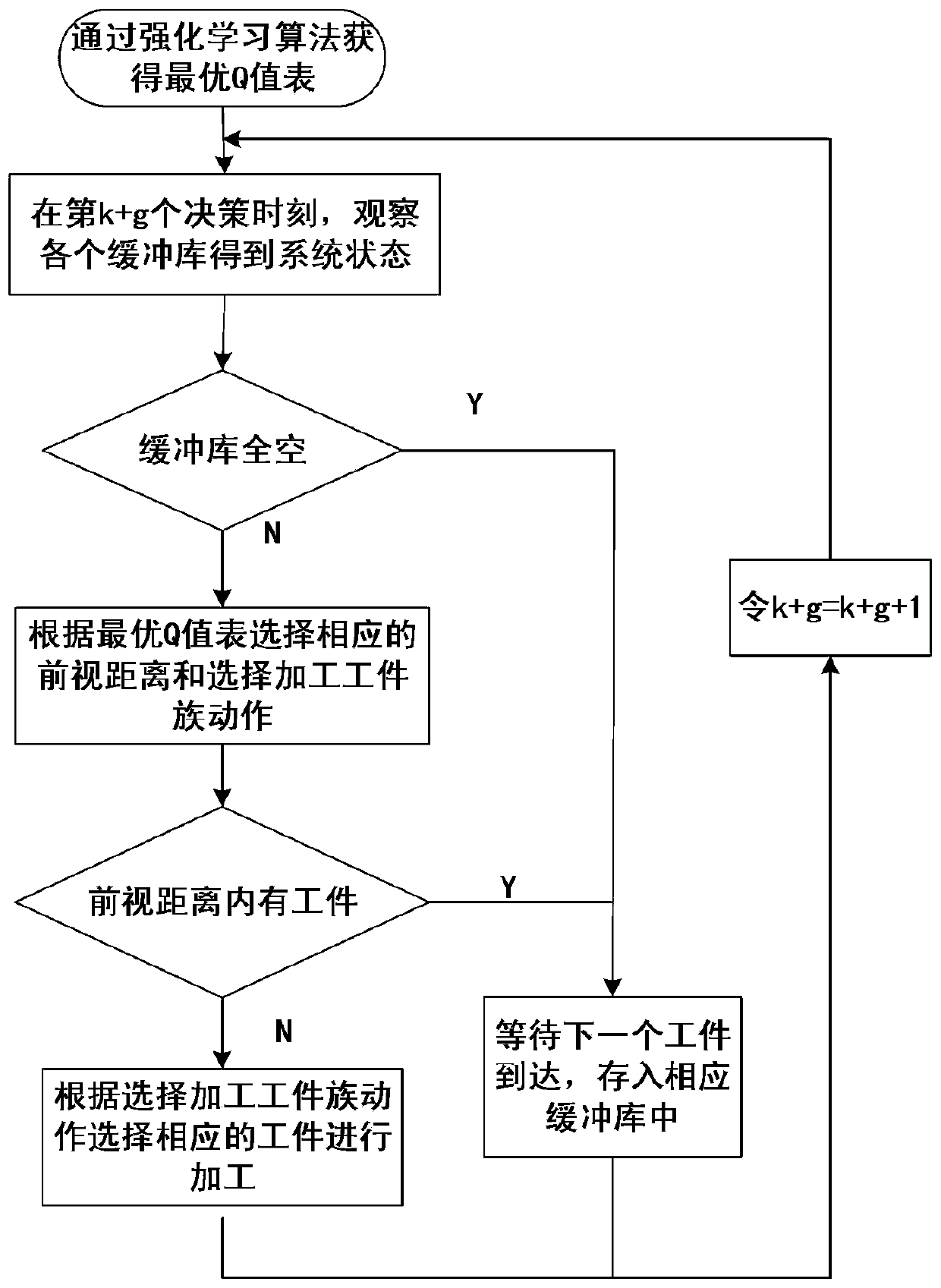

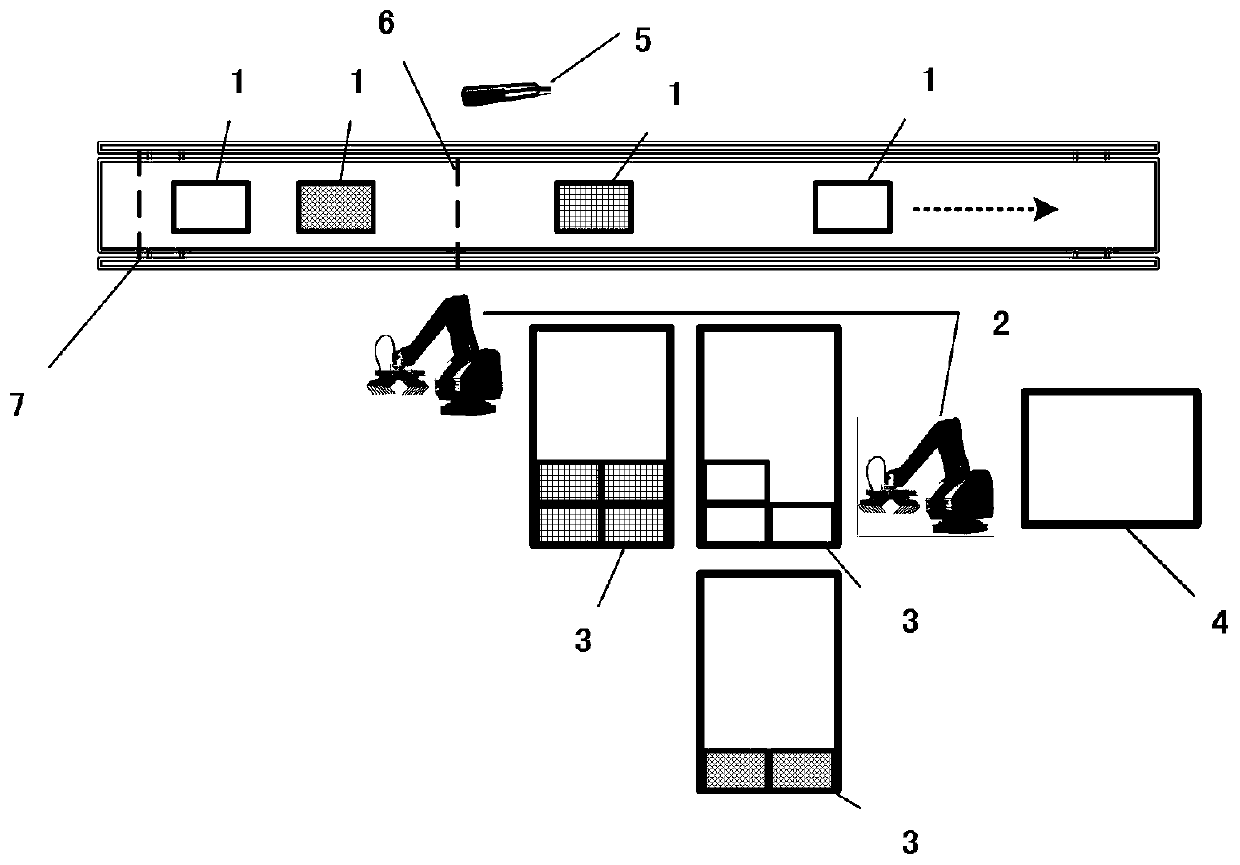

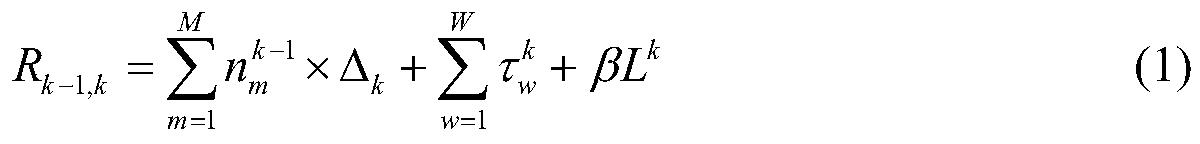

[0037] In this embodiment, an optimized control method for compatible workpiece families considering the forward-looking distance is applied to figure 2 In the stand-alone production system that is shown by the M types of workpieces conveyed on the conveyor belt 1, the automatic picking device 2, M buffer stores 3, the batch processor 4 with a capacity of K, and the infrared sensor 5; in the production system, M The workpiece 2 arrives randomly along the conveyor belt. When a workpiece arrives at the picking line, the automatic picking device 2 picks up the workpiece and puts it into the corresponding buffer store in 3, regardless of the picking process time. The M types of workpieces belong to M different compatible workpiece families, and the M workpiece families are sorted in descending order of processing rate. The compatible workpiece family means that the workpieces belonging to different families can be processed in the same batch; any mth The capacity of the buffer sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com