Workshop drying and ventilating system with humidity and temperature capable of achieving combined control

A combined control and ventilation system technology, applied in heating and ventilation control systems, heating and ventilation safety systems, ventilation systems, etc., can solve the problems of large power consumption, poor practicability, increased production costs, etc., to reduce production costs , Good practicability, and the effect of saving plant area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

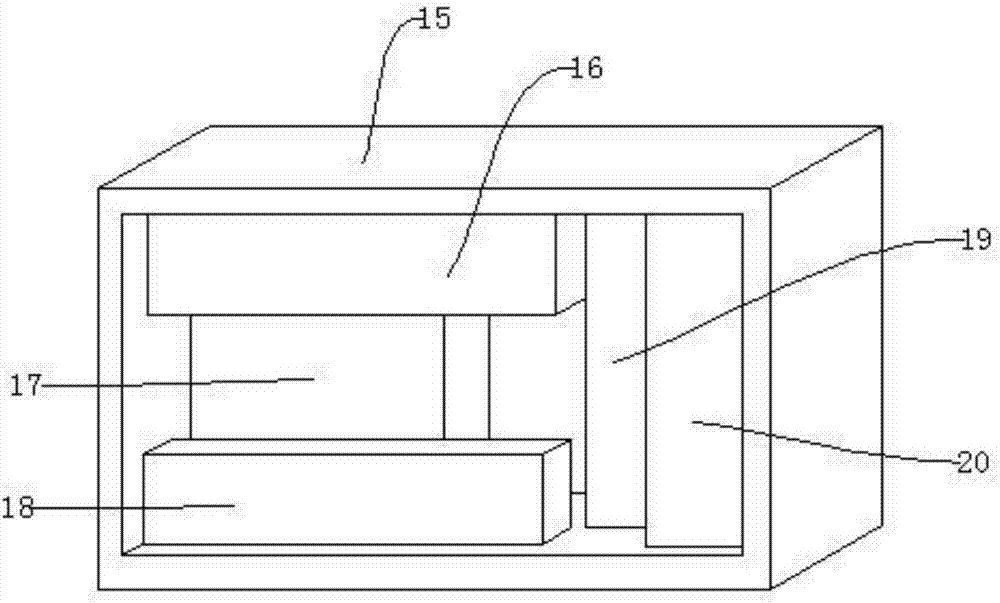

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as Figure 1-Figure 2 As shown, a workshop drying and ventilation system with joint control of humidity and temperature includes a workshop building 1, and a solar panel 2 is arranged on the roof of the workshop building 1, and the solar panel 2 is used for drying and ventilation system of the workshop. Working power supply, the whole system is powered by the solar panel 2, does not consume mains power, energy saving and environmental protection, the solar panel 2 is electrically connected with the solar power generation controller 4, and the solar power generation controller 4 is used to control the The solar panel 2 stores the generated direct current in the battery pack 5, the solar power generation controller 4 is also electrically connected to the battery pack 5, the battery pack 5 is used for storing electric energy, and the battery pack 5 is also connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com