Supersonic aircraft air inlet channel with adjustable throat area and adjusting method

A technology of air inlet and supersonic speed, which is applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc. It can solve the problems of engine thrust reduction, large aircraft resistance, and large air inlet total pressure loss coefficient, etc., to achieve shortened length , Wave system configuration is flexible, and the adjustment process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

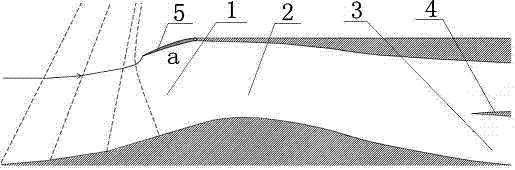

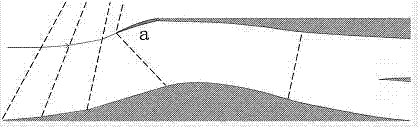

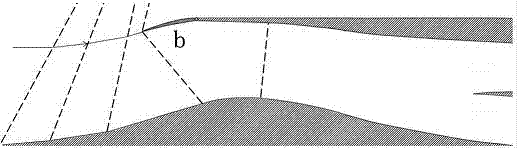

[0021] Such as Figure 1-6 As shown, a supersonic aircraft air intake with adjustable throat area, the air intake includes a lip 1, a throat 2 and an expansion section 3, the part of the air intake located at the front end of the lip 1 is a multi-section wedge surface, The air inlet forms a constricted section between the lip 1 and the throat 2. In the air inlet, the throat 2 has the smallest cross-sectional area. A displacement mechanism (not shown in the figure) is arranged in the air inlet. Vanes 4 are arranged in the air inlet through the displacement mechanism, and the displacement mechanism can control the blades 4 to move back and forth and rotate in the air inlet.

[0022] Further, the blades 4 are arranged on the side walls on both sides of the air inlet through a displacement mechanism.

[0023] Further, the blade 4 is a supersonic airfoil or a supersonic airfoil.

[0024] Further, a fin 5 is provided on the upper part of the lip 1 of the air inlet, and one end of t...

Embodiment 2

[0035] Such as Figure 7-12 As shown, the difference between Embodiment 2 and Embodiment 1 is that the blades 4 are at least 2 pieces, and the blades 4 are set to 3 pieces here, specifically the upper blade, the middle blade and the lower blade, and the 3 blades 4 and the wing The combination of slices 5 makes the adjustment process more precise and effective.

[0036] A method for adjusting the air inlet of a supersonic aircraft with an adjustable throat area. In the take-off state, the blades 4 in the air inlet are all in the expansion section 3 of the air inlet, and the fins 5 on the upper part of the lip 1 rotate downwards to reduce the air intake. The opening area of the small lip 1; when the starting Mach number of the air inlet is reached and lower than the design Mach number of the aircraft, the fins 5 are gradually adjusted to rotate upwards until reset. After the fins 5 are reset, the upper blades of the expansion section 3 are sequentially , the middle blade and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com