Breeding of Yeast Strain Producing Nitrilase and Its Application in Biotransformation of Nitrile Compounds

A nitrilase and yeast strain technology, applied in the field of industrial biology, can solve problems such as yeast strains that have not yet been seen, and achieve the effects of outstanding nitrile transformation ability, low production cost, and increased accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Enrichment and screening process of bacterial strains

[0035] Collect soil samples around the nitrile compound factory building. When collecting soil samples, first use a small shovel to shovel off the surface soil, and collect soil samples at a depth of 5-15cm. Take 1g of the collected soil and sludge samples, dissolve them in 10mL of 0.9% normal saline, shake fully at 30°C for 30min, and let stand; take 1mL of the soil suspension and put it into the Erlenmeyer flask containing screening medium (50mL / 250mL) was cultured in a reciprocating shaker at 120 rpm at 30°C; after 48 hours, 100 μL of turbid culture solution was spread on a solid screening medium plate, and the plate was placed in a constant temperature incubator for upside-down culture, and cultured at 30°C 48h; Pick a large and strong single colony grown on the screening medium plate, transfer to a fresh screening medium, streak and separate, and transfer for 3 to 5 generations.

[0036] Carry out re-scre...

Embodiment 2

[0049] This example illustrates the method of culturing CGMCC No.12935 inserted into the fermentation medium to obtain bacteria with high activity and high biomass, and biotransforming 3-hydroxypropionitrile to produce 3-hydroxypropionic acid.

[0050] The composition of the fermentation medium (g / L) is: yeast powder 7.5g, peptone 15g, NaCl 1g, KH 2 PO 4 2g, K 2 HPO 4 2g, glycerol 15g, 3-hydroxypropionitrile 1g, pH 7.2;

[0051] Insert CGMCC No.12935 into the medium with 3% inoculum amount, culture at 30°C, 120rpm reciprocating shaker for 36h, centrifuge at 12000rpm for 5min to collect the cultured bacteria, wash the bacteria with 100mM, pH7.2 sodium phosphate buffer cells 2 to 3 times, and resuspend the bacteria in the buffer.

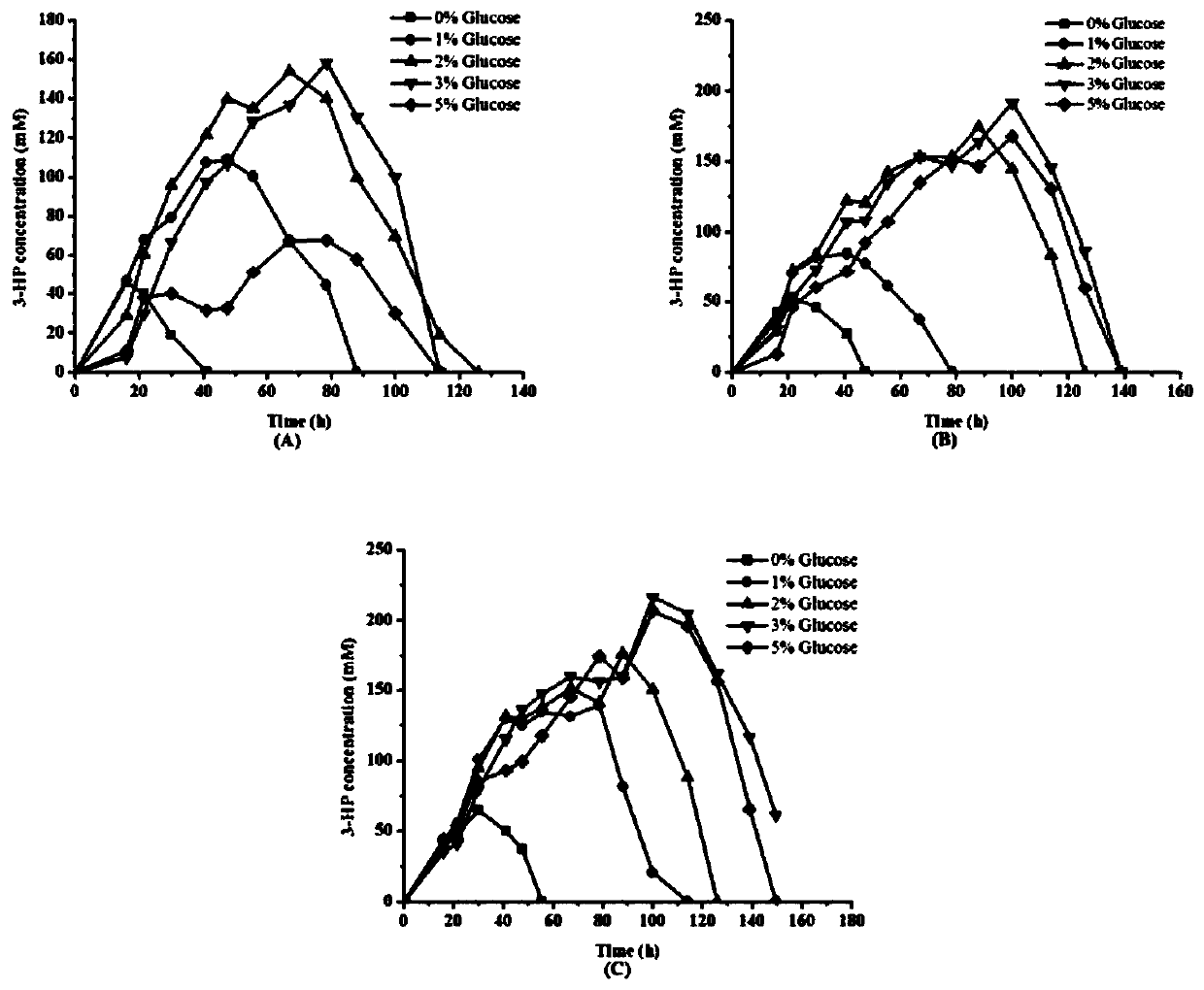

[0052] Mix the substrate solution with the bacterial suspension, and make the final concentration of the substrate 300mM, control the culture conditions at 30°C, 120rpm in a reciprocating shaker, and carry out the transformation reaction. After 3...

Embodiment 3

[0054] Collect the bacteria from the culture medium by centrifugation, wash the bacteria with 100mM, pH7.2 sodium phosphate buffer 2 to 3 times, resuspend to make the bacteria suspension, mix the substrate solution and the bacteria suspension, and make The final concentration of the substrate was 400mM, and the culture conditions were controlled. The transformation reaction was carried out in a reciprocating shaker at 30°C and 120rpm. After 41 hours, the substrate was completely transformed, and the cumulative concentration of 3-hydroxypropionic acid detected at 21.5 hours was the highest, which was 52.90mM .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com