Automatic online feeding and welding equipment and method

A technology of automatic feeding and welding equipment, applied in welding equipment, metal processing equipment, auxiliary devices, etc., can solve the problems of heavy workload of operators, increase of cost and labor cost, and large proportion of equipment space, so as to improve the product quality. Quality and productivity, reduced effort and required costs, smaller footprint effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

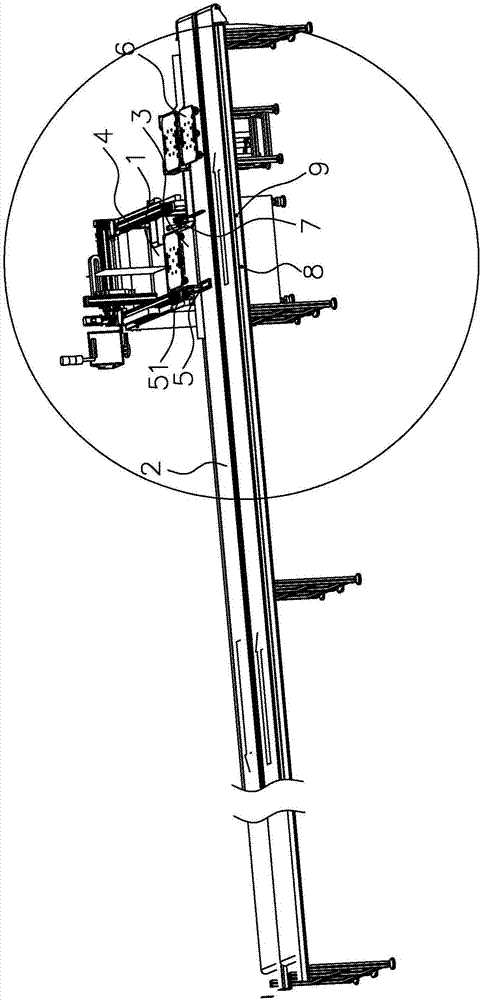

[0025] like figure 1 As shown, an online automatic feeding welding equipment disclosed by the present invention includes a workbench 1 and a controller. An assembly line 2 is provided on one side of the workbench 1, and the assembly line 2 is vertically connected to the workbench 1. In the length direction, push-pull mechanism, lifting mechanism 3 and four-axis module mechanism 4 are arranged sequentially. The four-axis module mechanism 4 is connected with a solder mechanism, and workbench 1 is provided with a blocking mechanism corresponding to the connection between assembly line 2 and workbench 1 The assembly line 2 is provided with a bearing tool 6 for placing the PCB board, and one side of the assembly line 2 is fixedly provided with an in-position detection device 8 and a blocking detection device 9 corresponding to the connection between the assembly line 2 and the workbench 1, and the in-position detection device 8 and the blocking The detection device 9 is arranged se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com