Data acquisition monitoring system and acquisition monitoring method based on CAN bus and OPC (OLE for process control) technology

A technology of CAN bus and data acquisition, applied in the direction of digital transmission system, transmission system, data exchange network, etc., can solve the problem of high cost and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing of specification sheet and embodiment, the present invention is described in detail based on CAN bus and OPC technology data acquisition monitoring system and data acquisition monitoring method:

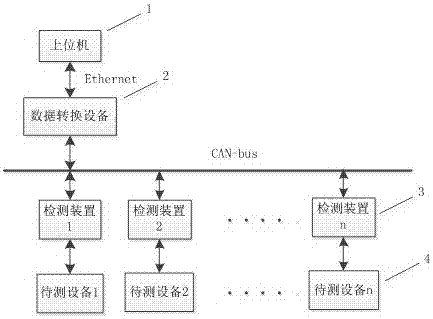

[0051] Such as figure 1 As shown, a data acquisition and monitoring system based on CAN bus and OPC technology includes a host computer 1, a data conversion device 2 connected to the host computer 1 through a network cable, and the data conversion device 2 is connected to multiple detection devices 3 through CAN communication lines , the detection device 3 is connected to the corresponding device under test 4 .

[0052] The upper computer 1 is an industrial computer or an industrial control machine.

[0053] The data conversion device 2 adopts CANET-2E-U to realize data conversion, and realizes the conversion between CAN2.0B format data and TCP format data.

[0054] The detection device 3 adopts a CAN2.0B communication format me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com