Low-light-loss tube lamp adjusting structure

A technology for adjusting structure and downlight, applied in the field of LED lighting, can solve the problems of limited light control capability, low light output efficiency, light loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

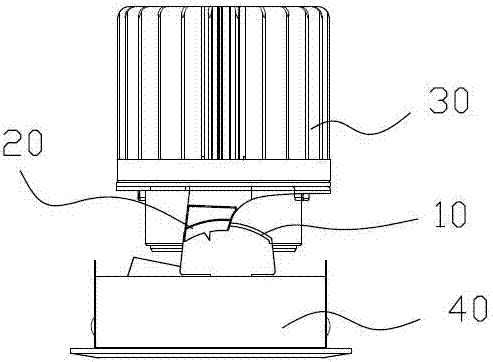

[0025] A low light loss downlight adjustment structure, such as figure 1 As shown, it is connected between the downlight light source part 30 and the light adjustment part 40, and is used as an adjustment mechanism for the output light angle of the downlight light source. The position of the adjustment structure is the same as that of the pin shaft type adjustment structure in the prior art. . It comprises an arc guide part 10 and a sliding part 20 . The arc guide part 10 is used to provide a deflection track for angle adjustment of the light source part. And the sliding part 20 slides on the arc guide part.

[0026] In terms of connection, the arc-shaped guide part 10 is connected to the light-rectifying part 40. The light-rectifying part 40 in the present invention refers to the components at the front end of the downlight, which mostly includes a reflective cup and a fixed frame for fixing the reflective cup. The light output by the part 30 has the function of adjustment...

Embodiment 2

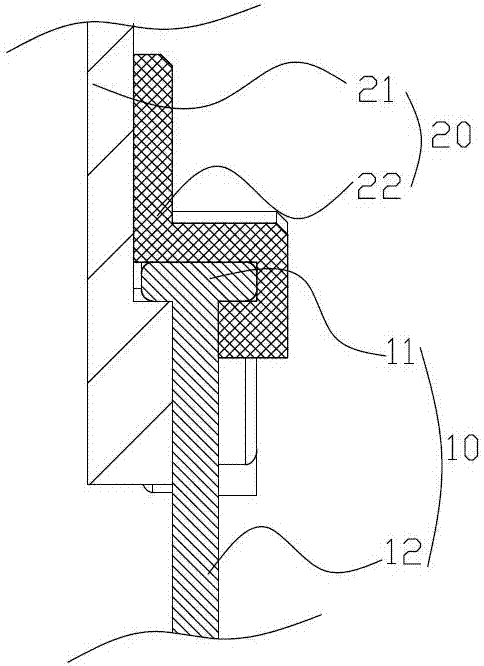

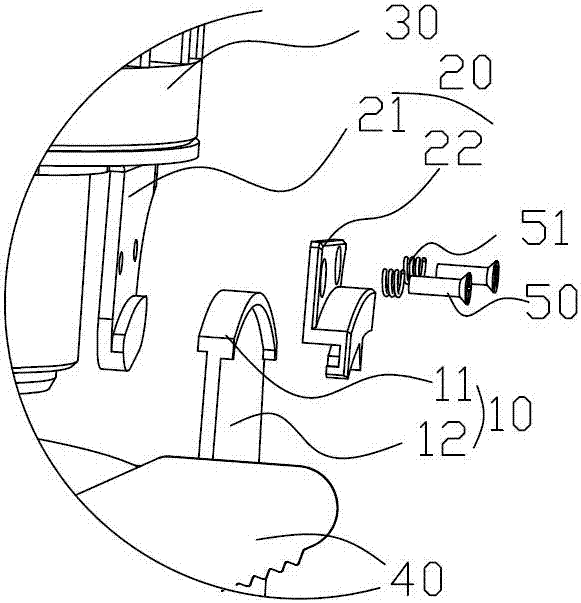

[0029] As a further optimization of embodiment 1, the difference between this embodiment and embodiment 1 is: as figure 2 and image 3 As shown, the arc guide 10 includes a guide bracket 11 and an arc guide rail 12 , wherein the guide bracket 11 is fixed on the lightening unit 40 , and the arc guide rail 12 is connected to the top of the guide bracket 11 . In order to facilitate the connection between the arc-shaped guide part 10 and the sliding part 20, the arc-shaped guide rail 11 in this embodiment is an arc-shaped ridge, and its cross-section is circular or polygonal, and this embodiment is rectangular. The sliding part 20 is sleeved on the arc guide rail 11 , so that the sliding part 20 moves along the arc guide rail 11 .

[0030] In terms of the specific structure of the sliding part 20, the sliding part 20 includes a first clamping part 21 and a second clamping part 22, and the first clamping part 21 and the second clamping part 22 cooperate to wrap the arc-shaped gui...

Embodiment 3

[0035] As a further optimization of embodiment 1, the difference between this embodiment and embodiment 2 is: as Figure 4 As shown, the arc-shaped guide rail 11 in this embodiment is an arc-shaped groove. The arc-shaped groove is also arranged on the top of the guide bracket 11 .

[0036] Regarding the sliding part 20 , the first clamping part 21 and the second clamping part 22 of the sliding part 20 are also arranged on the arc-shaped guide rail 11 , but components passing through the arc-shaped guide rail 11 are required to ensure positioning. In this embodiment, the screw 50 connecting the first clamping portion 21 and the second clamping portion 22 is passed through the arc-shaped guide rail 11 , which plays the role of connection and positioning at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com