Semiconductor polymer taking compound graphene/carbon black as conductive medium and preparation method

A technology of composite graphene and conductive media, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of destroying the conjugated structure of graphene, high usage of graphene carbon black, and affecting practical application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

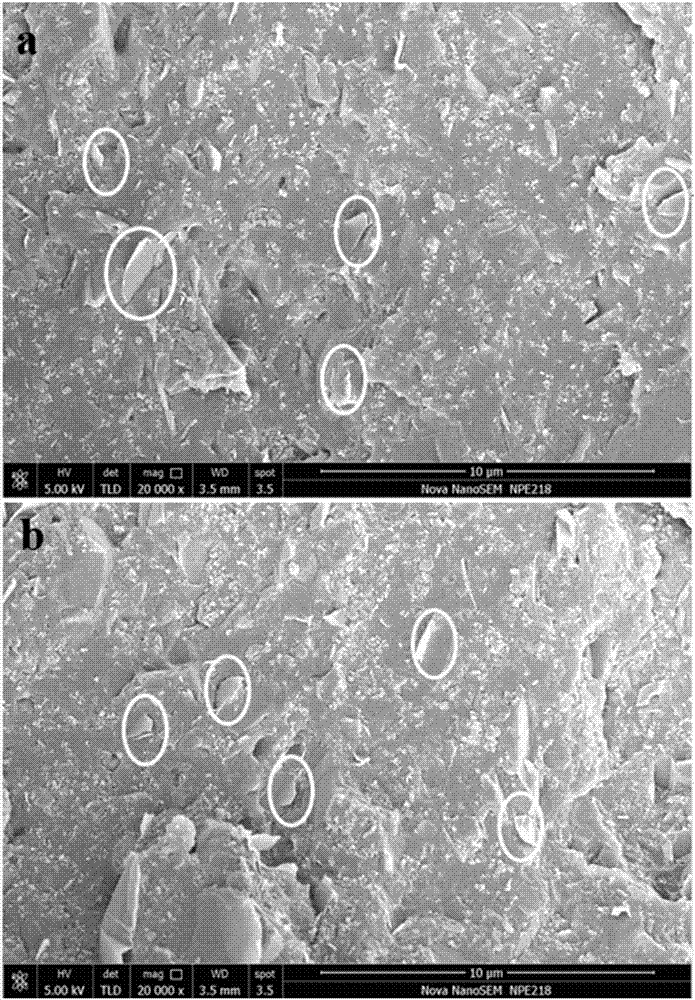

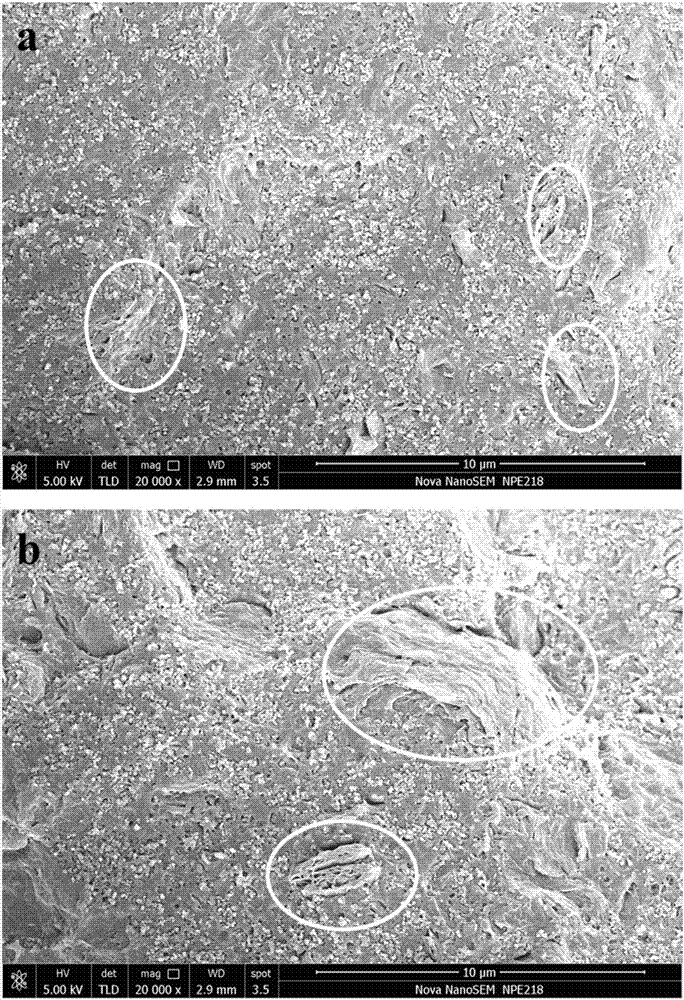

Image

Examples

Embodiment 1

[0066] A composite graphene / carbon black is a semiconducting polymer with a conductive medium, and its raw material components are as follows: EVA69.1%, graphene / polyaniline composite 1.7%, inorganic filler ultrafine modified kaolin 10.4%, carbon black 17.5% % and cross-linking agent DCP 1.3%; among them, the VA content in EVA is 28%;

[0067] Used graphene / polyaniline compound adopts following steps to prepare:

[0068] S1, disperse 10g graphene in 2000mL NMP, ultrasonic 1h, obtain graphene dispersion liquid;

[0069] S2. Add 450 mL of dilute hydrochloric acid solution with a concentration of 1M, 15 g of DBSA, and 15 g of aniline, and stir for 30 min;

[0070] S3. Add 450 mL of 1M dilute hydrochloric acid solution dissolved with 34.2 g of ammonium peroxodisulfate, and react at 0-5° C. for 6 h to obtain a graphene / polyaniline composite solution, which is freeze-dried to obtain final product.

[0071] The composite graphene / carbon black is prepared by the following solution m...

Embodiment 2

[0075] A kind of compound graphene / carbon black is the semiconductor polymer of conductive medium, and its raw material composition is as follows: EVA61.4%, graphene / polyaniline 2.5%, inorganic filler superfine modified kaolin 13.8%, carbon black 19.9%, Cross-linking agent DCP1.2% and lubricant zinc stearate 1.2%; wherein, the VA content in EVA is 28%;

[0076] Used graphene / polyaniline compound adopts following steps to prepare:

[0077] S1, disperse 10g graphene in 2000mL NMP, ultrasonic 1h, obtain graphene dispersion liquid;

[0078] S2. Add 450 mL of dilute hydrochloric acid solution with a concentration of 1M, 15 g of DBSA, and 15 g of aniline, and stir for 30 min;

[0079] S3. Add 450 mL of 1M dilute hydrochloric acid solution dissolved with 34.2 g of ammonium peroxodisulfate, and react at 0-5° C. for 6 h to obtain a graphene / polyaniline composite solution, which is freeze-dried to obtain final product.

[0080] The composite graphene / carbon black is prepared by the fo...

Embodiment 3

[0084] A compound graphene / carbon black is a semiconducting polymer with a conductive medium, and its raw material components are as follows: EVA 70%, graphene / polyaniline composite 3%, inorganic filler ultrafine modified kaolin 11%, carbon black 15% and cross-linking agent DCP 1%; wherein, the VA content in EVA is 28%;

[0085] Used graphene / polyaniline compound adopts following steps to prepare:

[0086] S1, disperse 10g graphene in 2000mL NMP, ultrasonic 1h, obtain graphene dispersion liquid;

[0087] S2. Add 450 mL of dilute hydrochloric acid solution with a concentration of 1M, 15 g of DBSA, and 15 g of aniline, and stir for 30 min;

[0088] S3. Add 450 mL of 1M dilute hydrochloric acid solution dissolved with 34.2 g of ammonium peroxodisulfate, and react at 0-5° C. for 6 h to obtain a graphene / polyaniline composite solution, which is freeze-dried to obtain final product.

[0089] The composite graphene / carbon black is prepared by the following solution method as the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com