Preparation method of Bi2O2CO3 photocatalyst, prepared Bi2O2CO3 photocatalyst and application

A photocatalyst, chloride technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. To achieve the effect of simple and convenient steps, low energy consumption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment B

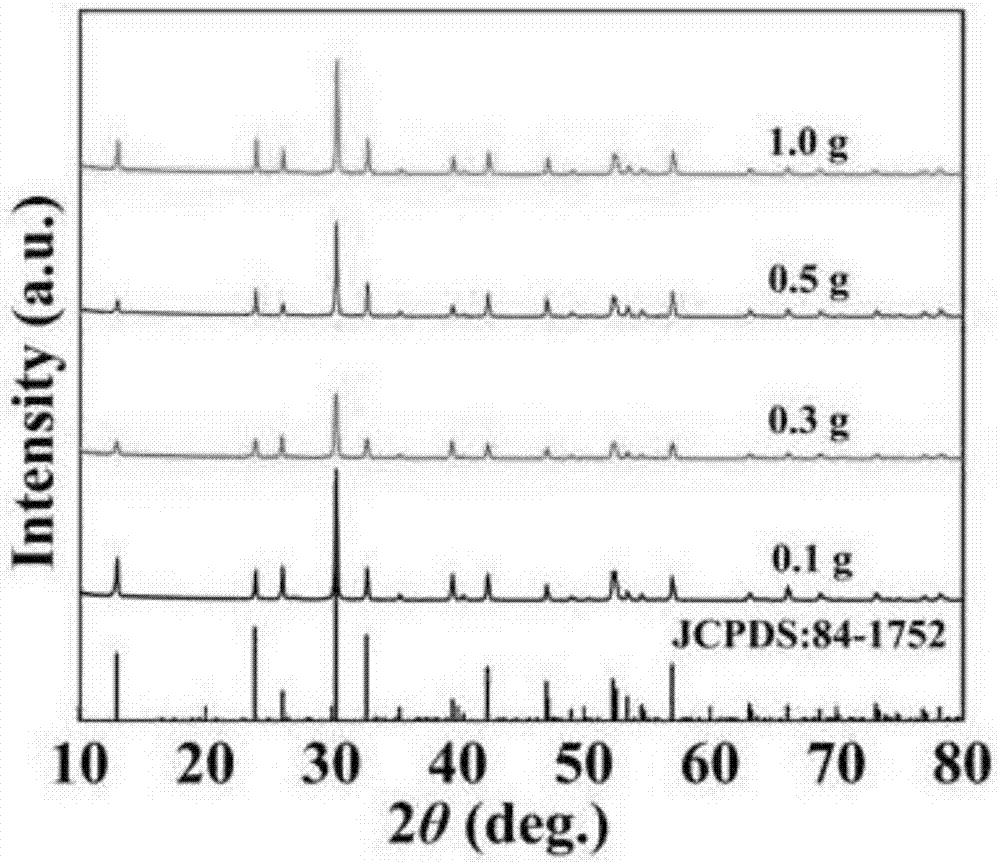

[0032] Example of the present invention Bi 2 o 2 CO 3The preparation method of photocatalyst, described method comprises the steps:

[0033] (1) adding water to bismuth nitrate and urea, and adding dropwise a chloride solution, stirring to form a bismuth precursor;

[0034] The molar dosage ratio of described bismuth nitrate and urea is: 1: (1-20);

[0035] (2) Adjust the pH value of the bismuth precursor to 5.0-6.5 with an alkaline solution to form a reactant;

[0036] (3) Reacting the reactant at 150-160°C for 24-30h to obtain a precipitate;

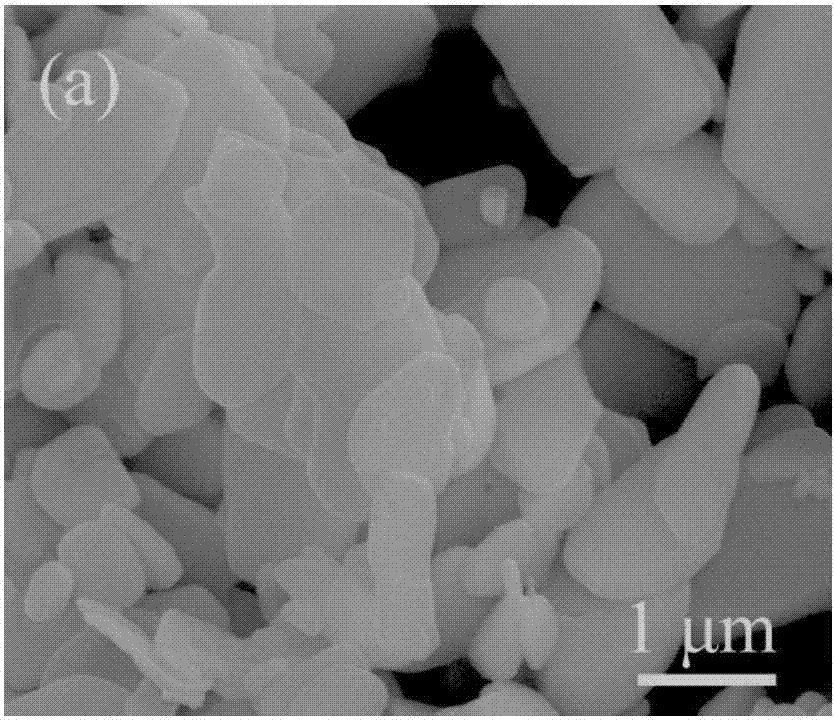

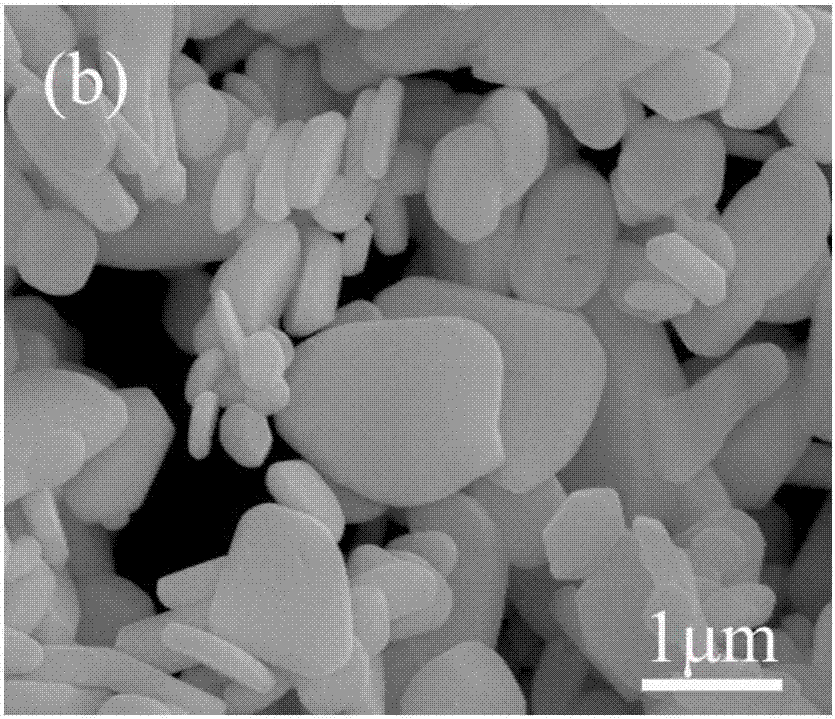

[0037] (4) The precipitate obtained in step (3) is washed and dried to obtain a sheet-like structure of Bi 2 o 2 CO 3 Micro-nano sheet photocatalyst powder.

[0038] Described bismuth nitrate raw material generally selects to contain crystal water, for example commercially available Bi(NO 3 ) 3 ·5H 2 O, bismuth nitrate decomposes into basic salt in water. The chloride is easily soluble in water, and it is prepared into a so...

Embodiment 1

[0045] Weigh 0.48507g of Bi(NO 3 ) 3 ·5H 2 O and 0.1g of urea in a beaker; prepare a potassium chloride solution with a concentration of 0.2mol / l and a potassium hydroxide solution of 1mol / l; add 25ml of ultrapure water to the beaker, and add 10ml of the prepared solution dropwise to the cup The above-mentioned 0.2mol / l potassium chloride solution, and after stirring at room temperature for 0.5h, a certain concentration of bismuth precursor is formed; the bismuth precursor in the beaker is transferred to the reaction kettle, and the stirring is continued; the above-mentioned 1mol / l hydrogen Potassium oxide solution adjusts the pH value of the bismuth precursor to 6.0; conducts a hydrothermal reaction at 160°C for 24 hours to obtain a precipitate; washes the precipitate with deionized water and absolute ethanol several times, and then uses a vacuum drying oven Dry at a temperature of 40°C to obtain a sheet-like structure Bi 2 o 2 CO 3 Micro-nano sheet photocatalyst powder....

Embodiment 2

[0047] Weigh 0.48507g of Bi(NO 3 ) 3 ·5H 2 O and 0.3g of urea in a beaker; prepare a potassium chloride solution with a concentration of 0.2mol / l and a potassium hydroxide solution of 1mol / l; add 25ml of ultrapure water to the beaker, and add 10ml of the prepared solution dropwise to the cup 0.2mol / l potassium chloride solution, and after stirring at room temperature for 0.5h, a certain concentration of bismuth precursor is formed; transfer the bismuth precursor in the beaker to the reaction kettle and continue stirring; use 1mol / l potassium hydroxide The pH value of the bismuth precursor was adjusted to 6.0 in the solution; the reaction kettle was subjected to a hydrothermal reaction at 160°C for 24 hours to obtain a precipitate; Drying at a temperature of ℃, the sheet-like structure Bi can be obtained 2 o 2 CO 3 Micro-nano sheet photocatalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com