An integrated clutch-transmission system with a clutch cage carrying gearwheels

A technology of transmission gears and power transmission systems, which is applied in the directions of transmission parts, belts/chains/gears, control devices, etc., to achieve the effect of simplifying the structure, compacting the structure and reducing the axial structure space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

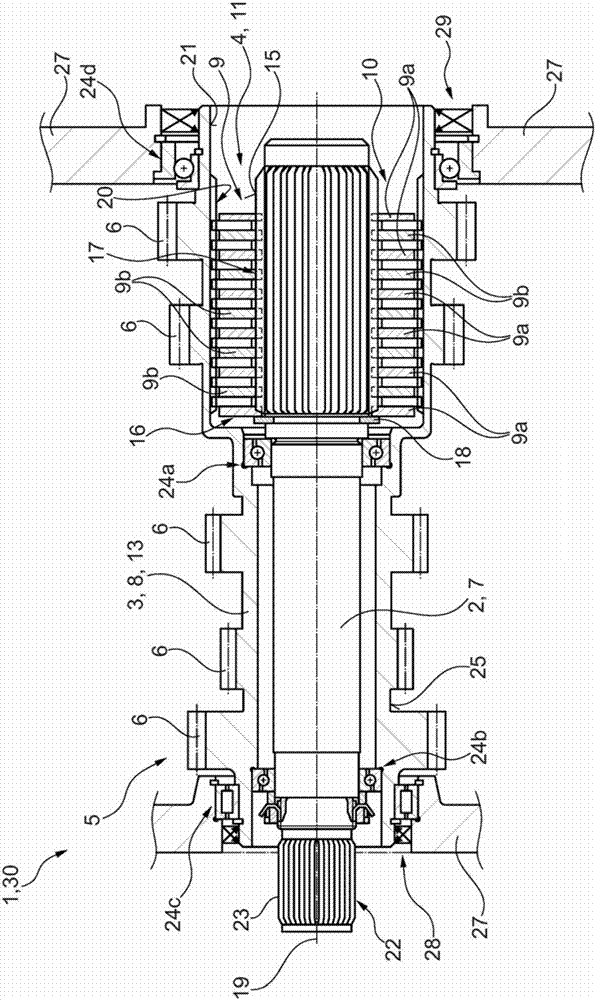

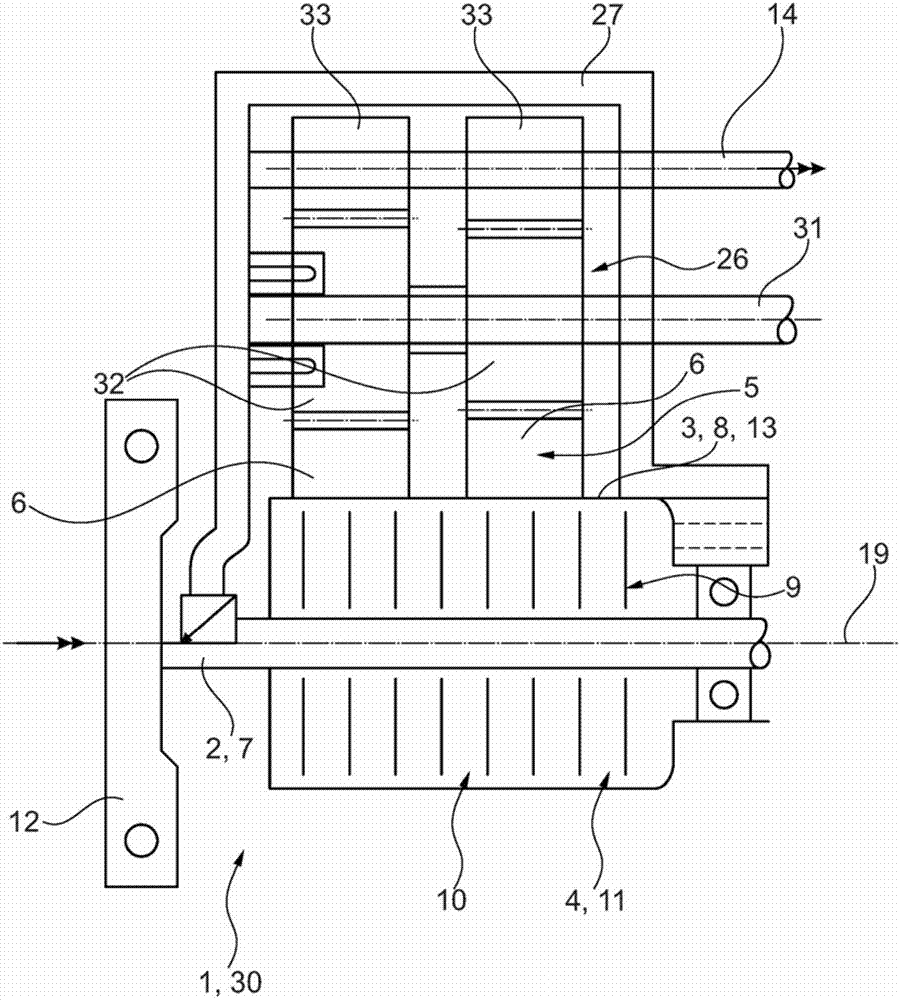

[0029] combine figure 2 , first of all, the installed state of the clutch transmission system 1 according to the invention according to a preferred exemplary embodiment can be seen in principle. The clutch transmission system 1 is intended to be arranged in the drive train of the motor vehicle, viewed in the line of force / torque, between the internal combustion engine of the motor vehicle and the driven wheels / tyres of the motor vehicle. The clutch transmission system 1 forms a transmission 30 in this embodiment. The transmission 30 is designed here as a manual transmission, but is not restricted to this embodiment. According to a further embodiment, the transmission 30 is also designed as an automatic transmission, for example an automated / automatic dual clutch transmission.

[0030] During operation, the first rotating part 2 of the clutch transmission system 1 is connected in a rotationally fixed manner to the output shaft of the internal combustion engine, which is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com