Honeycombed inflation-free tire

A non-pneumatic tire, honeycomb technology, applied in the direction of non-pneumatic tires, tire parts, transportation and packaging, etc., can solve the problems of large duty cycle, easy deformation of tire stress point, heavy solid tire, etc. The effect of large ratio, material saving and high duty ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

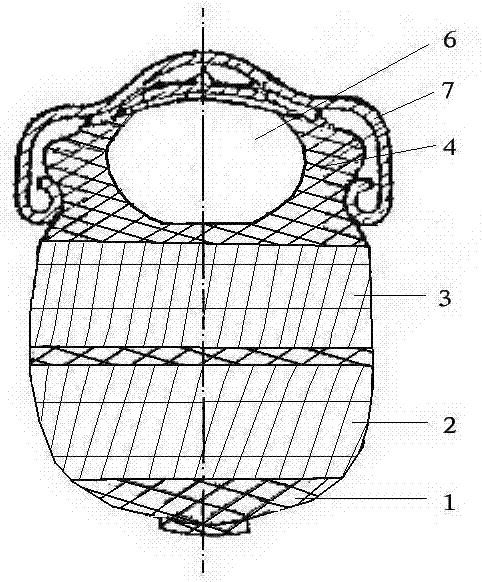

[0011] figure 1 and figure 2 Among them, the honeycomb type air-free tire is made of rubber injection molding, and its characteristics are:

[0012] The side surface of the tire adopts a honeycomb hollow structure. The honeycomb holes are all regular hexagons with the same size. According to the special structure of the tire, the honeycomb structure is specially treated and applied to the tire. The tire is composed of two rows of holes in the upper row of holes 2 and the lower row of holes 3. The characteristic is that all the holes are regular hexagonal. The centerlines 5 of the corners are all perpendicular to the tire tread 1.

[0013] Further, the bottom of the tire 4 is a groove 6 structure, when the tire is installed on the steel ring, a space of the groove 6 will be formed between the bottom of the tire 4 and the steel ring 7, so that the tire can generate cushioning force.

[0014] A typical example is that the side length b of the regular hexagon of the honeycomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com