Continuous automatic production device and production method of metal thin film plate

A metal thin film and production device technology, applied in the field of building decoration materials, can solve the problems of expensive metal plates, non-continuous production, limited application range, etc., achieve stable mechanical performance, increase adhesion, and reduce use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

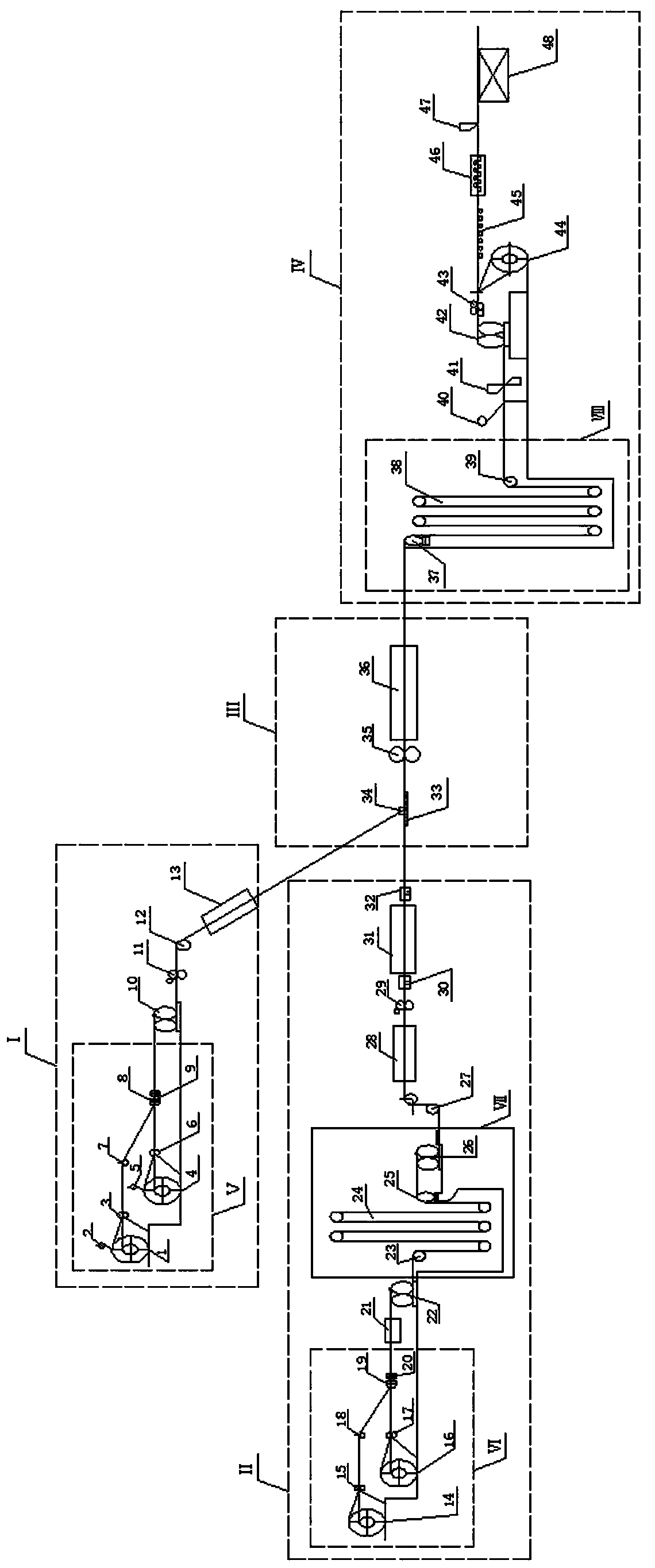

[0038] Such as figure 1 As shown, a continuous automatic production device for metal thin film plates includes an upper steel plate processing unit I, a lower steel plate processing unit II, a composite unit III, and a post-processing unit IV.

[0039] The upper steel plate processing unit I includes the upper steel plate continuous uncoiling device V, the upper steel plate tension roller 10, the upper steel plate roll coater 11, the upper layer steel plate first turning roll 12, and the upper layer steel plate heating furnace, which are arranged in sequence according to the direction in which the steel plate is conveyed. 13. The upper-layer steel plate continuous uncoiling device V includes a first uncoiler 1, a second uncoiler 4, an upper-layer steel plate sewing machine 8, and an upper-layer steel plate straightening machine 9. The first unc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com