Point paint mistake-proofing sleeve

A technology of spotting paint and sleeves, which is applied to hand-held tools and manufacturing tools, can solve the problems of loose bolts and falling off, personal injury, parts flying out, etc., and achieve the effect of easy replacement operation, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

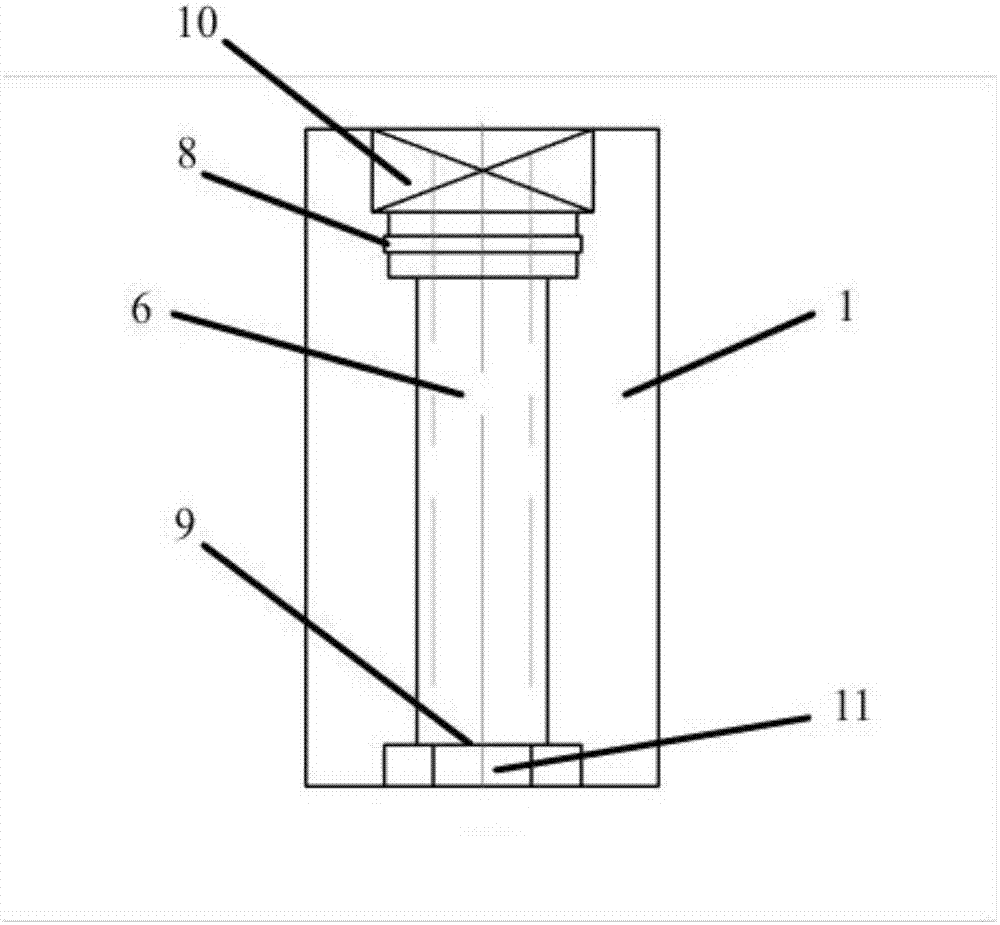

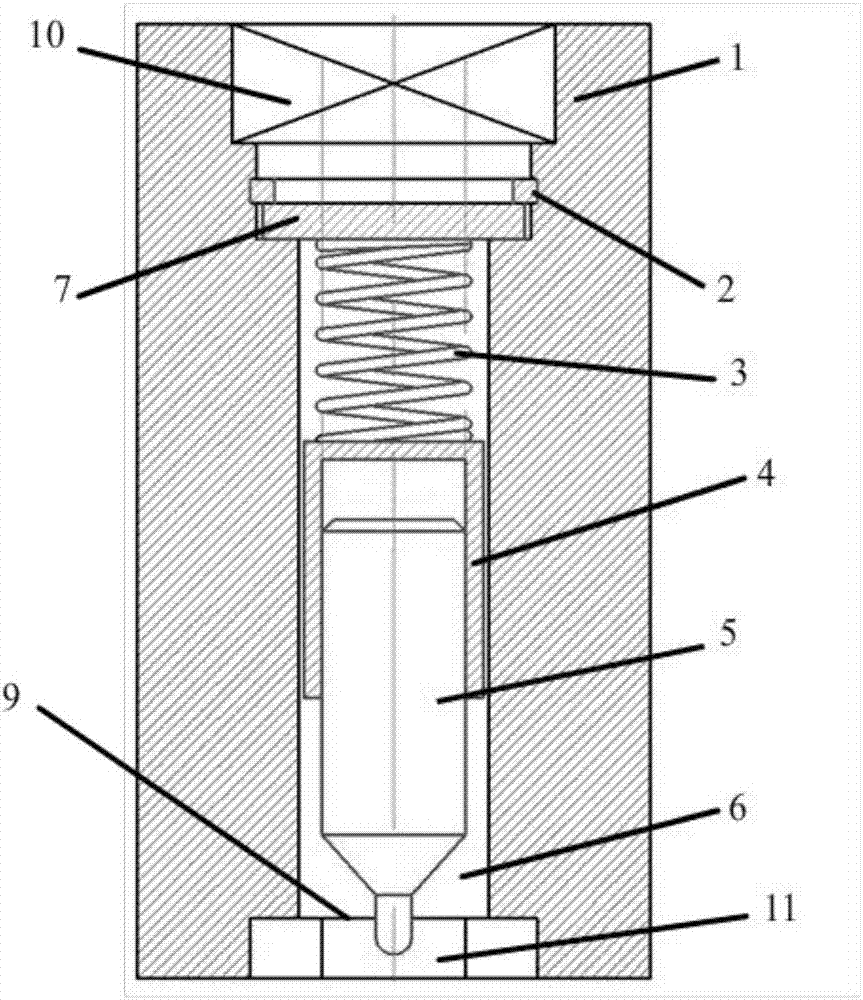

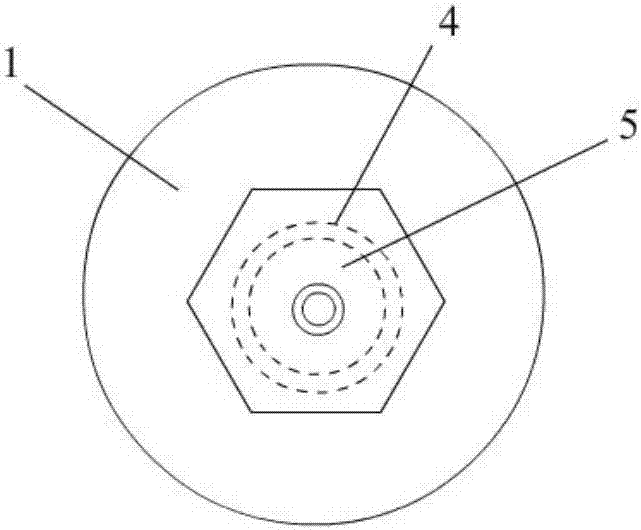

[0018] Such as Figure 1~4 Shown, a kind of sleeve that prevents error by spotting paint, comprises sleeve 1, spotting pen 5, spotting pen cover 4, spring support plate 7 and a spring 3; Described sleeve 1 upper end is provided with wrench square groove 10 , for mating connection with the wrench square to work with a wrench. At the same time, the lower end of the sleeve 1 is also provided with a bolt head groove 11; the inside of the sleeve 1 is provided with an inner chamber 6, and the inner chamber 6 communicates with the wrench square head groove 10; , the spot paint pen cover 4 is distributed in the inner cavity 6 of the sleeve 1, the lower end of the spring 3 bears against the upper end of the spot paint pen cover, and the upper end of the spring 3 bears against the spring support plate 7; at the same time, In order to block the spring support plate 7 at the upper part and prevent it from protruding upward, a retaining ring groove 8 is provided at the upper end of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com