Tearing machine

A frame and reducer technology, applied in the field of tearing machines, can solve problems such as increasing energy consumption and affecting work efficiency, and achieve the effects of improving work efficiency, reducing energy consumption and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A tearing machine according to the present invention will be further described in detail through specific examples below.

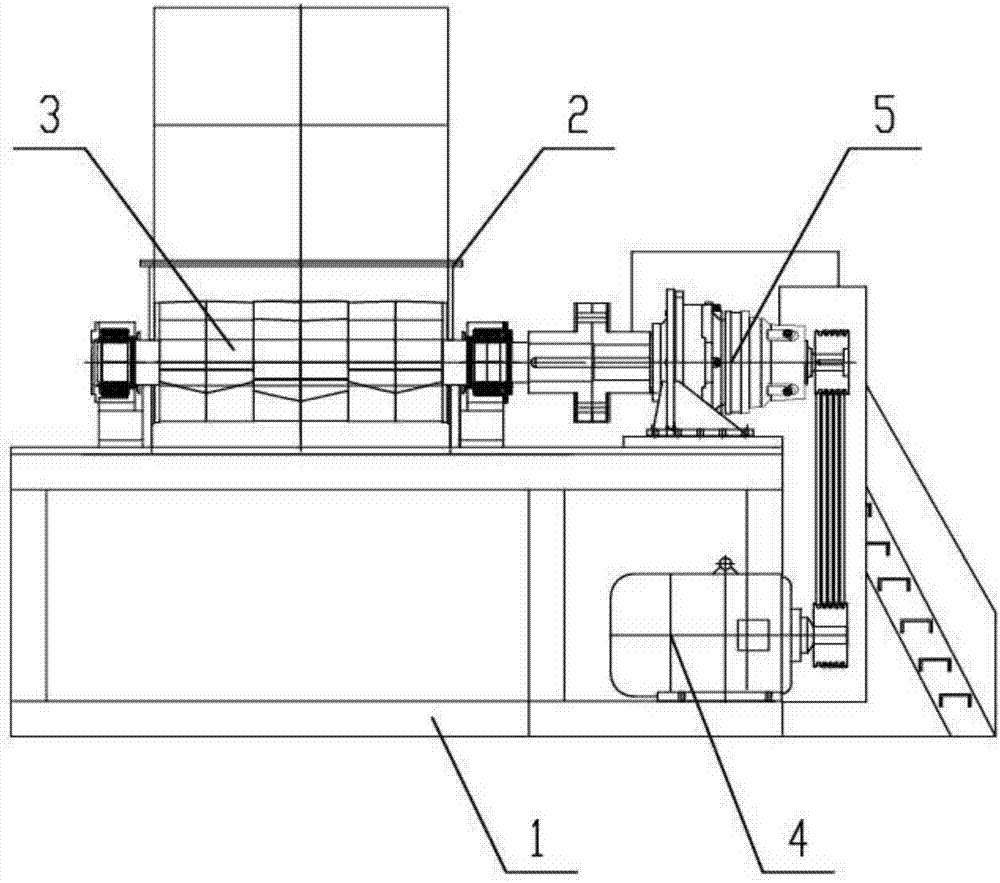

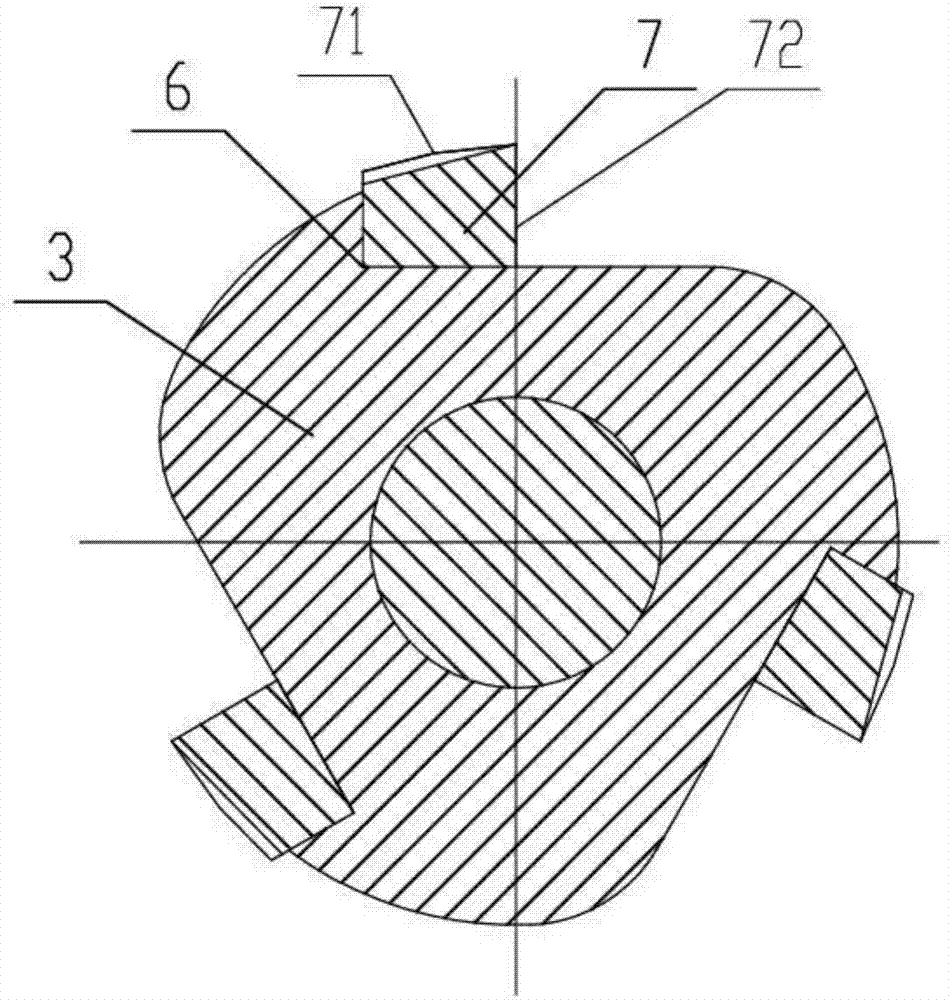

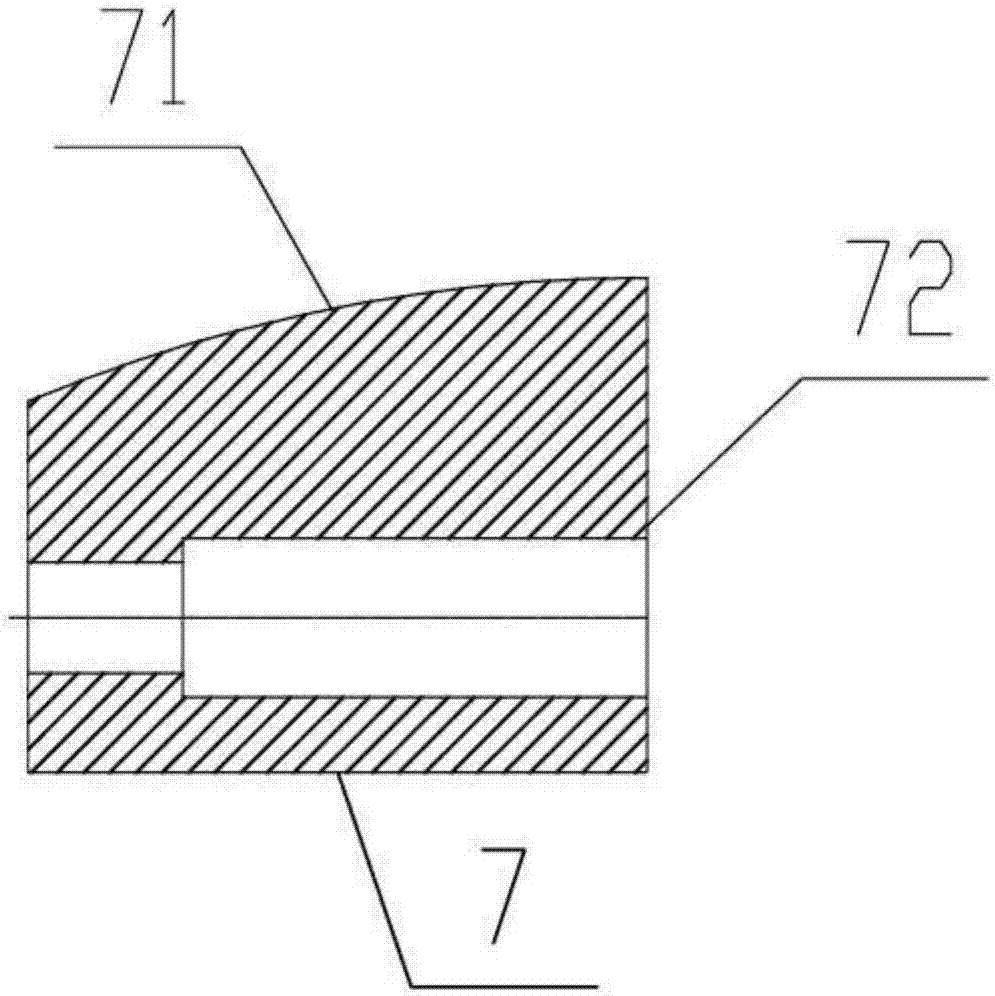

[0019] Such as figure 1 As shown, a tearing machine includes a frame and a material box 2 arranged on the frame 1, the material box 2 is provided with a main shaft 3, and the frame 1 is provided with a motor 4 and a reducer for driving the main shaft 3 to rotate 5. The outer wall of the main shaft 3 is provided with a plurality of bayonets 6 along the circumference, and a knife 7 is arranged in each bayonet 6, such as figure 2 , image 3 , Figure 4 As shown, the outer end surface 71 of the knife 7 is a convex arc surface, the outer surface 72 of the knife 7 is a slope, and the outer end surface 71 of the knife 7 protrudes from the outer wall of the main shaft 3 .

[0020] Such as figure 1 , figure 2 As shown, in this embodiment, the length direction of the main shaft 3 is divided into three sections, and the outer wall of each section is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com