Efficient screening equipment provided with magnetic bars for rice processing

A technology for rice processing and screening equipment, applied in the field of grain processing, can solve the problems of not meeting modern production requirements, inability to remove impurities and dust, and high noise, and achieve simple structure, high screening efficiency, and guaranteed screening grades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

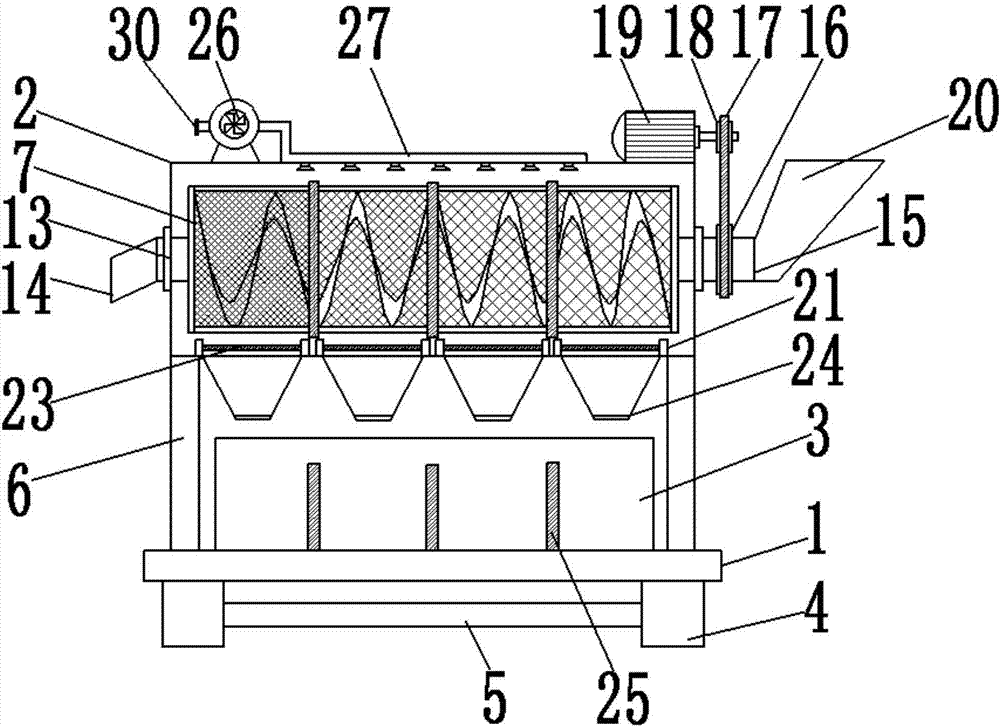

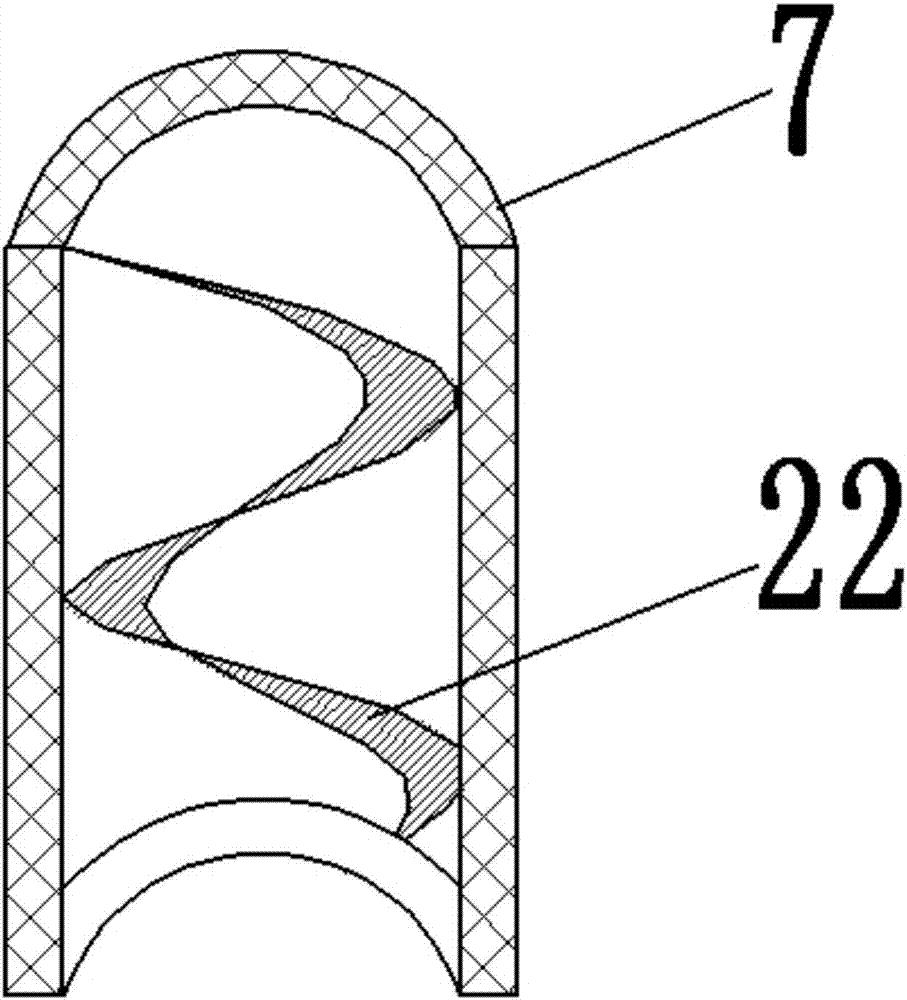

[0018] see Figure 1-4 , a high-efficiency screening device for rice processing with a magnetic bar, comprising a base 1, a screening chamber 2 and a receiving bin 3; the lower end of the base 1 is provided with a support leg 4; there are four support legs 4; the support leg 4 is provided with a reinforcing plate 5, so as to increase the stability of the base 1; the upper end of the base 1 is connected with the screening room 2 through the support column 6; the support column 6 is fixed on both sides of the upper end of the base 1; the screening room 2 Inside is provided with screening cage 7; Described screening cage 7 is fixed in the inside of screening chamber 2 by left rotating shaft 13 and right rotating shaft 15; Described left rotating shaft 13 and right rotating shaft 15 are hollow tubular structures, communicate with screening cage 7; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com