Ultrasonic garlic clove peeling device and method

An ultrasonic and garlic clove technology, applied in the field of ultrasonic garlic clove peeling devices, can solve the problems of difficult to guarantee peeling quality, high bruising rate, and high power consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

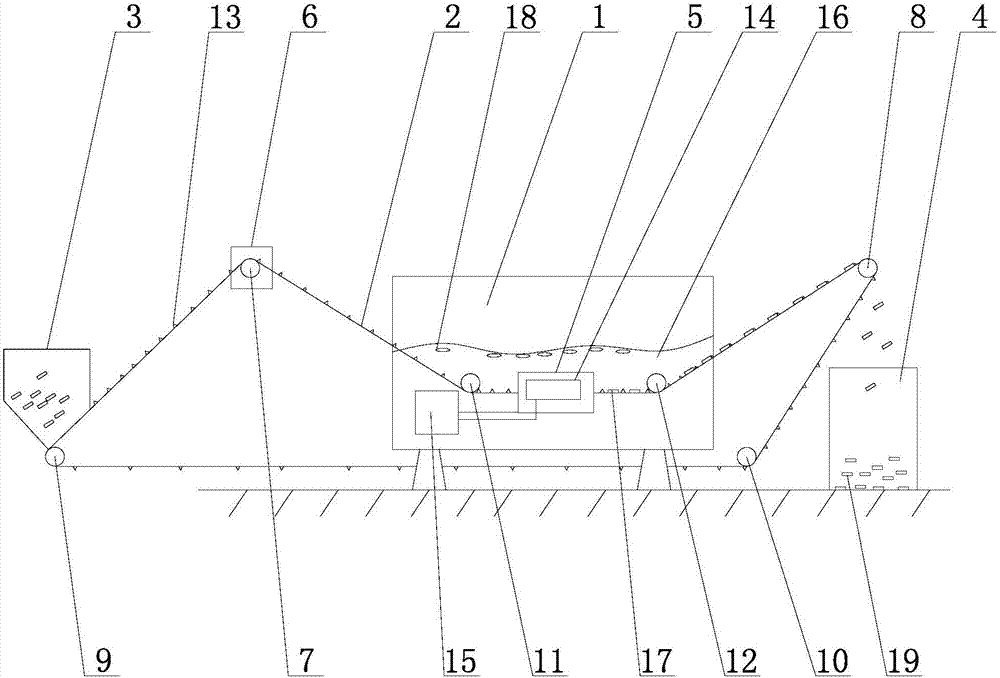

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] Such as Figure 1-2 As shown, an ultrasonic garlic peeling device includes a container 1, a conveyor belt 2 runs through the container 1, the conveyor belt 2 is installed on the driving device, one end of the conveyor belt 2 is connected to a feeding port 3, and the other end is connected to a Outlet 4, the inner wall of the container 1 is provided with an ultrasonic generator 5, through the design of the driving device, the conveyor belt 2, the container 1 and the ultrasonic generator 5, the transportation of garlic is realized, and ultrasonic waves are emitted to make the water vibrate and vibrate the garlic clove skin 18 Separate from the garlic clove 17, and then realize the peeling of the garlic clove 17, change the traditional garlic peeling method, have higher peeling efficiency, high peeling rate, and lower bruising rate.

[0027] The driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com