Plasma torch equipped with waveguide in which swirl flow collapses gas supply part

A plasma and gas supply technology, applied in the direction of plasma, manufacture of combustible gas, electrical components, etc., can solve the problems of reduced production efficiency of synthetic gas and inability to flow in, and achieve the goals of increasing reaction time, easy application, and increasing manufacturing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention that can achieve the object of the present invention will be described below with reference to the drawings. In the description of the present embodiment, the same components are given the same names and the same reference numerals, and additional description thereof will be omitted.

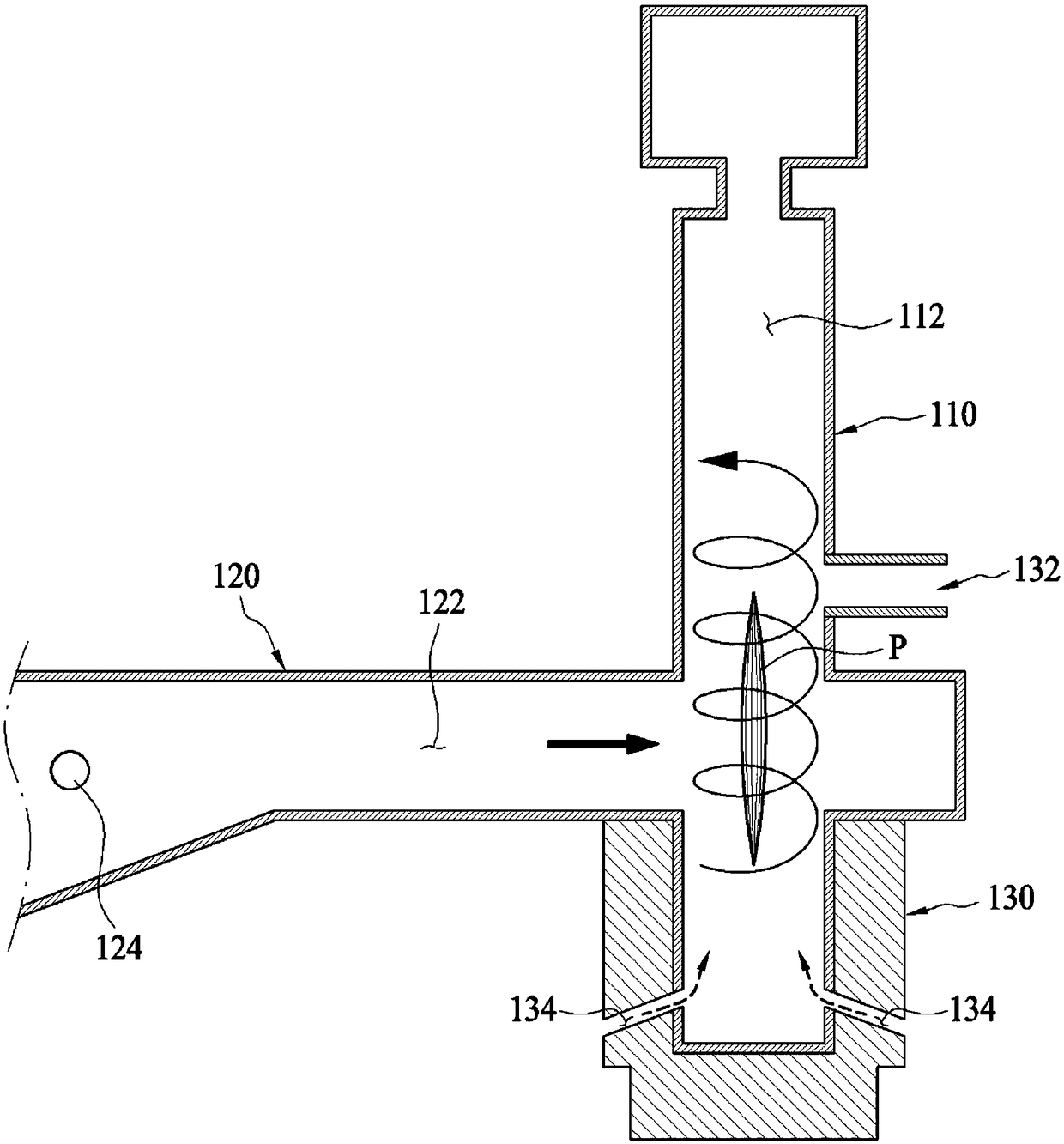

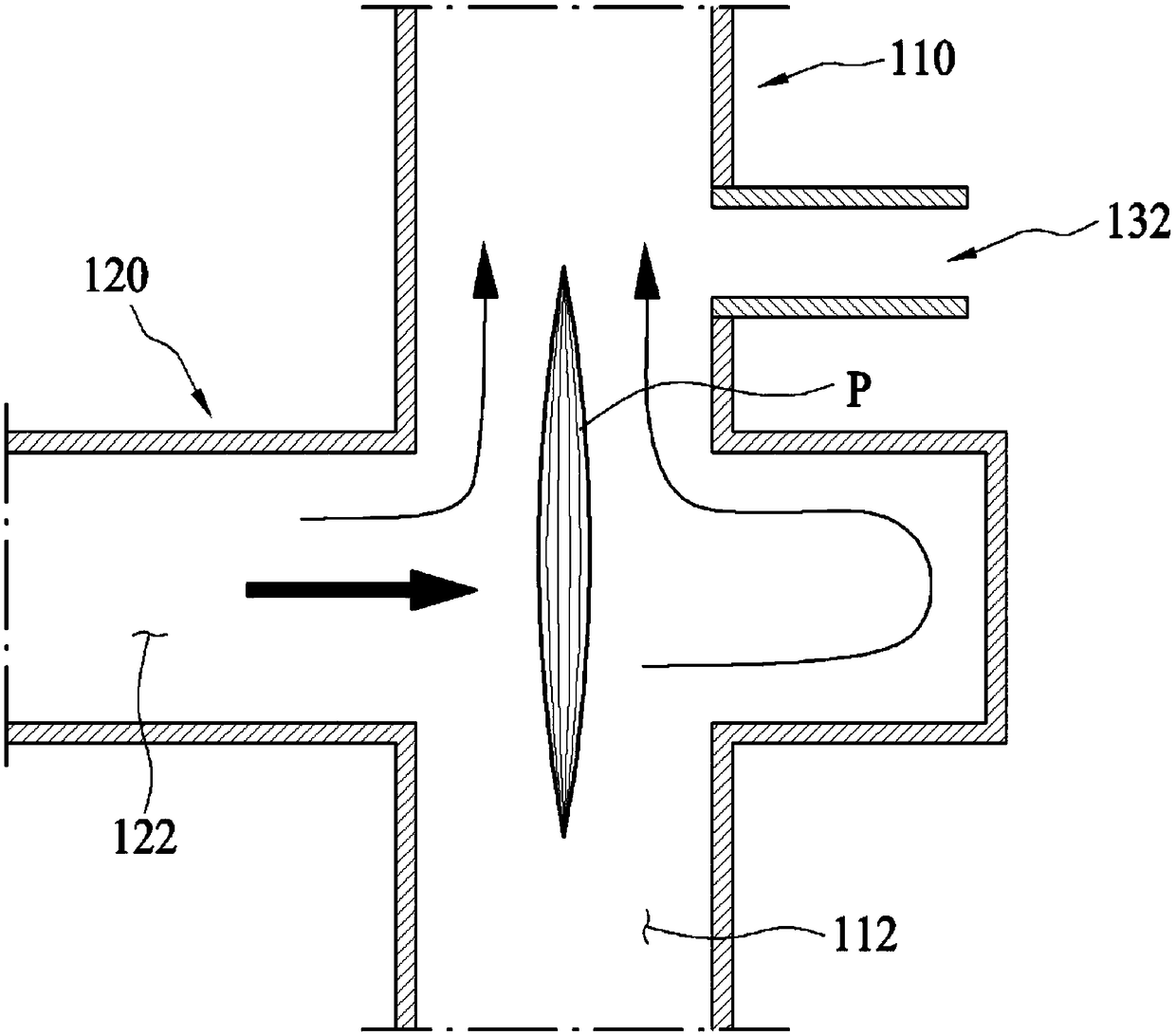

[0042] figure 1 is a sectional view showing the structure of the plasma torch according to the first embodiment of the present invention, figure 2 is a cross-sectional view showing a state where a swirl flow is injected through the waveguide 120 to disintegrate gas in the plasma torch according to the first embodiment of the present invention.

[0043] Such as Figure 1 to Figure 4 As shown, the plasma torch according to the first embodiment of the present invention includes a reactor 110 and a waveguide 120 .

[0044] The reactor 110 has a reaction space 112 formed therein, and includes a raw material injection part 114 and a swirl flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com