Grommet and electric wire with grommet

A technology of grommets and electric wires, which is applied in the field of grommets, and can solve problems such as gaps between grommets and through holes, deflection and deformation, etc., and achieve the effects of reducing weight, suppressing deformation, and improving waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

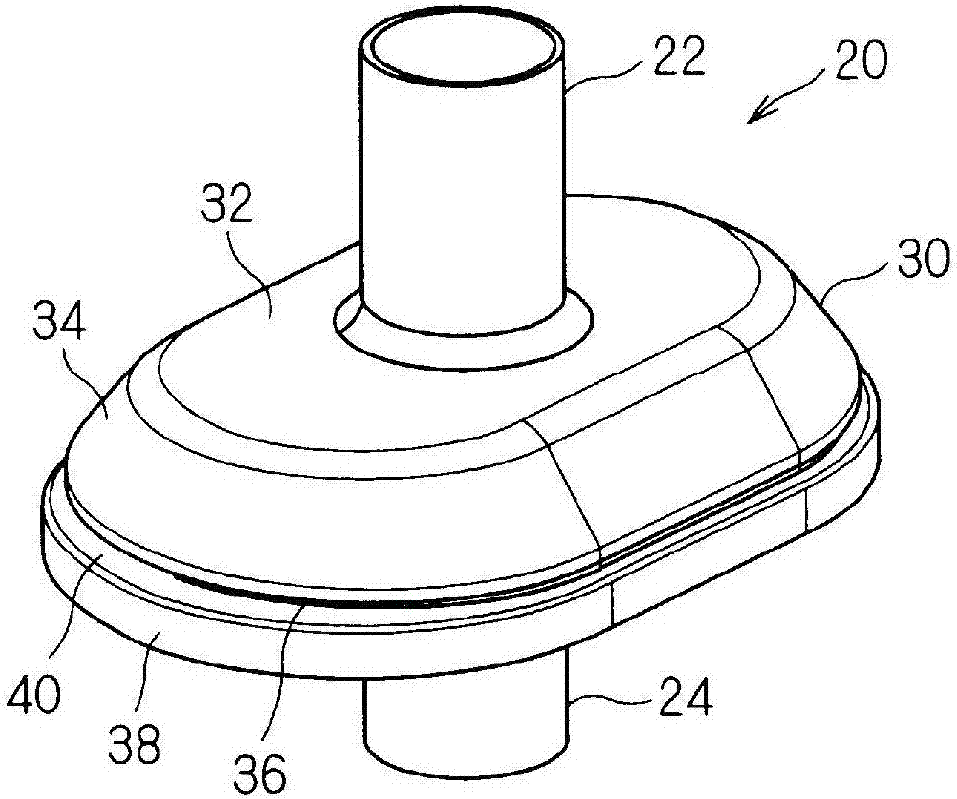

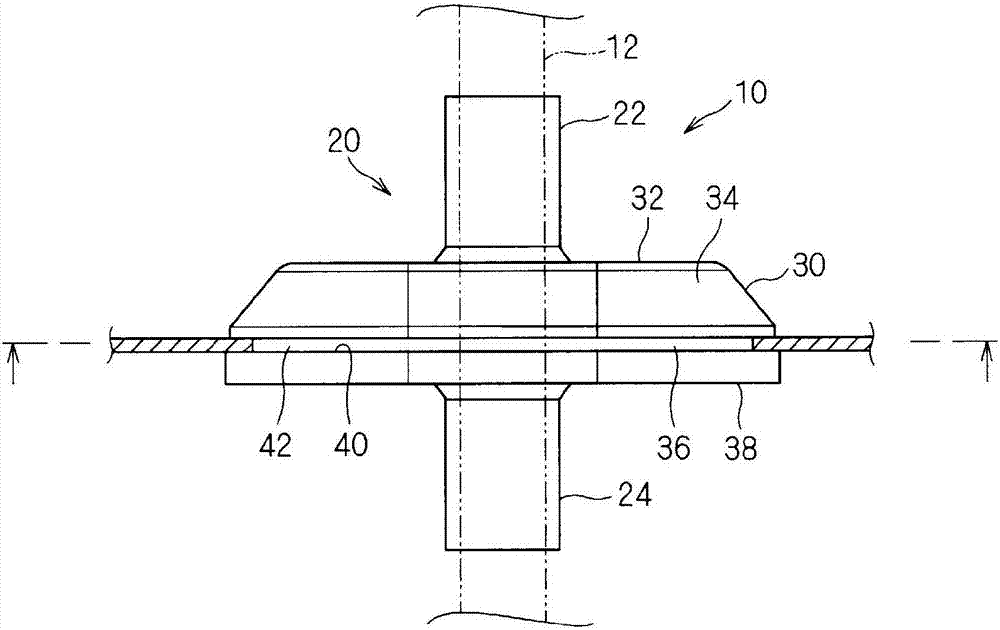

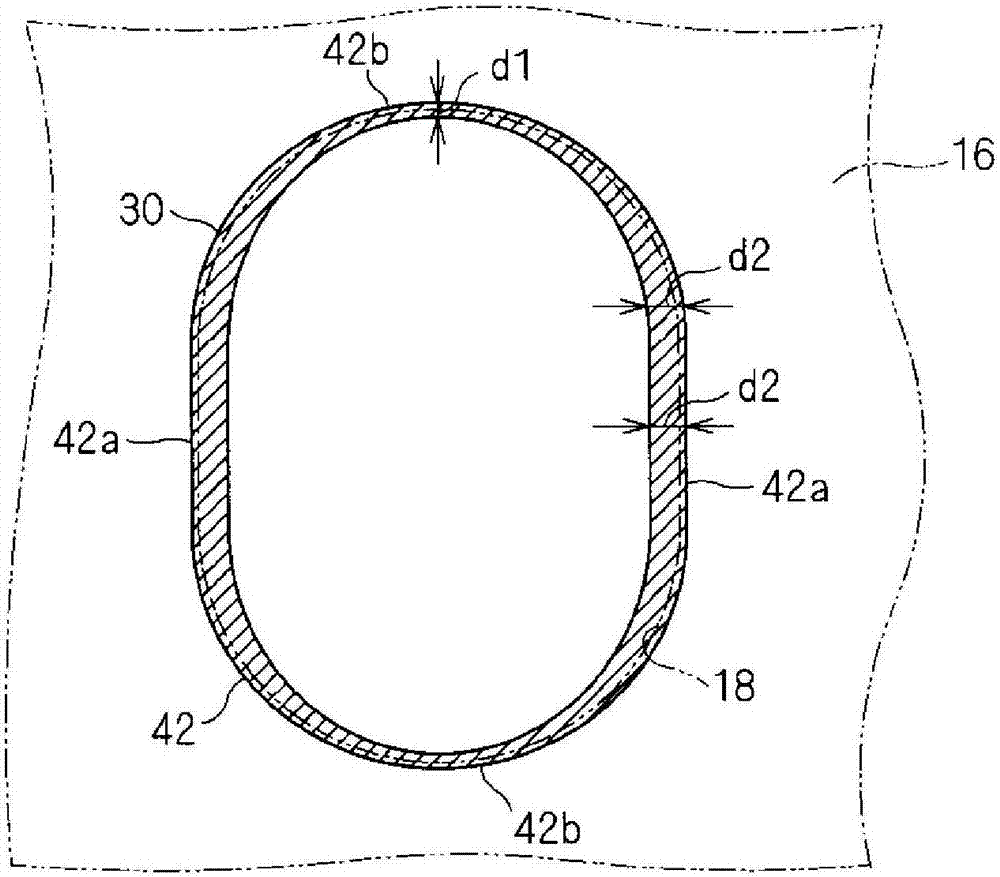

[0028] The grommet and the electric wire with the grommet according to the embodiment will be described below. figure 1 is a perspective view showing the grommet 20, figure 2 It is a schematic side view showing the state where the electric wire 10 with a grommet is attached to the panel 16 (that is, the attachment structure of the grommet for the electric wire 10 with a grommet). in addition, image 3 It shows the state in which the mounting portion 30 is projected onto the peripheral portion of the through hole 18 of the panel 16 with a cross-sectional shape perpendicular to its central axis (coincident with the central axis of the cylindrical portions 22 and 24 ) and cut through the plane of the annular groove 40 . In addition, in this projected state, the center of the cross-sectional shape coincides with the center of the through hole 18 .

[0029] The electric wire 10 with a grommet includes an electric wire 12 and a grommet 20 .

[0030] Here, the electric wire 10 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com