Purification method of easily polymerizable substances

A refining method and easy-to-polymerize technology, applied in the separation/purification of carboxylic acid compounds, separation methods, chemical instruments and methods, etc., to achieve the effects of improving production efficiency, reducing the chance of contacting chemical substances, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

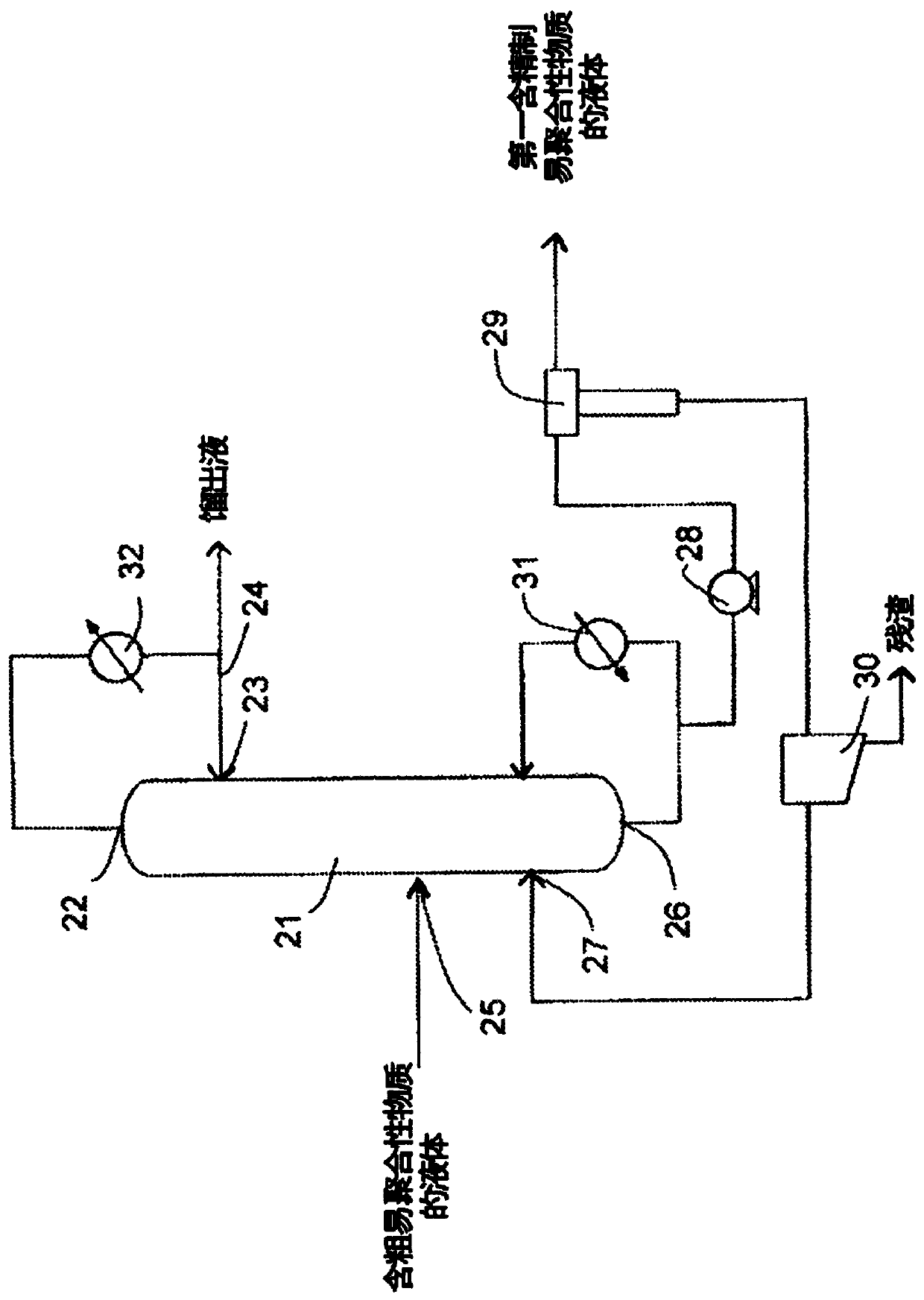

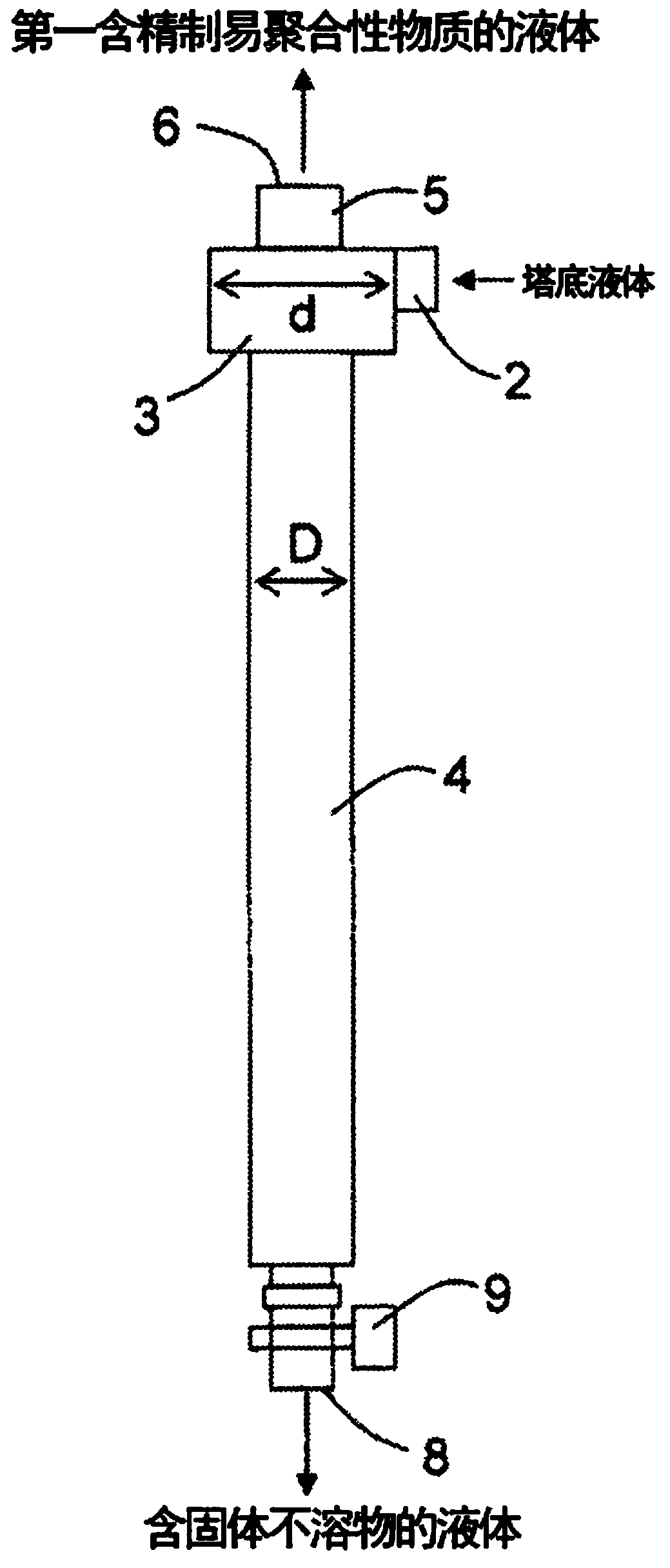

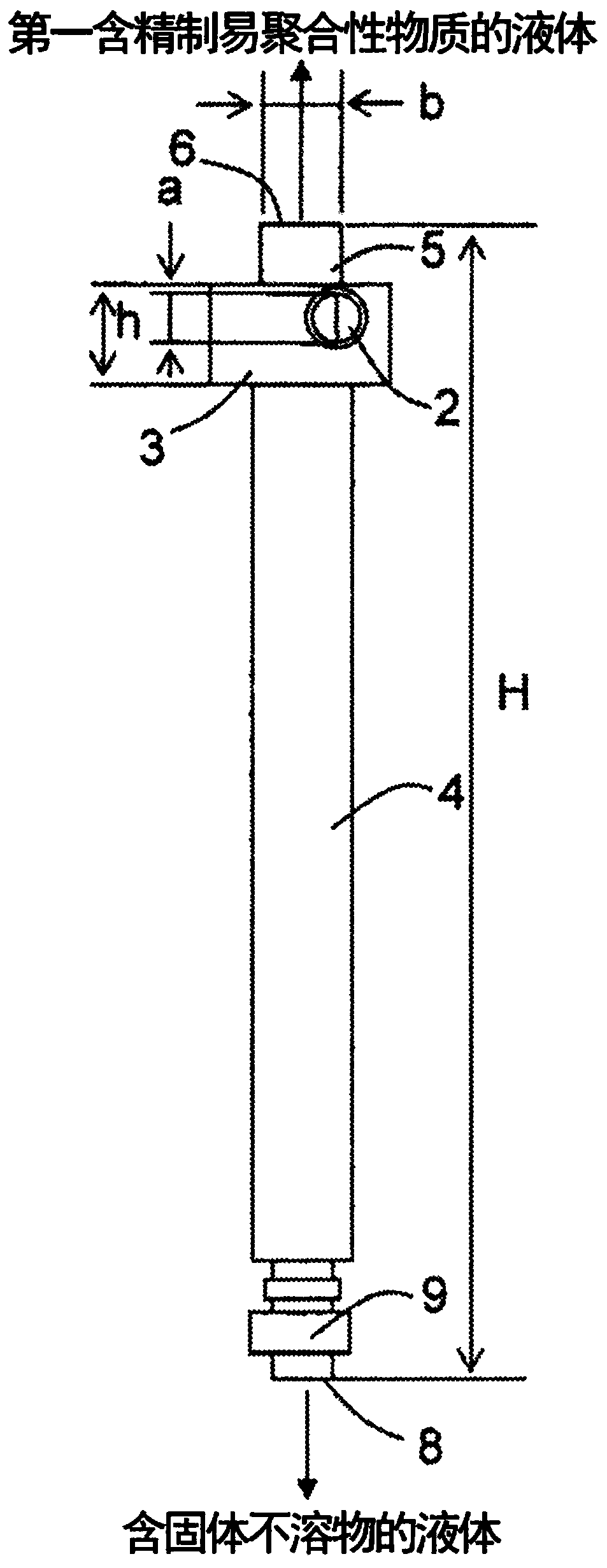

[0086] As a distillation column, the rectification operation of the crude acrylic acid-containing liquid was carried out using a distillation column equipped with a stainless steel non-weir perforated plate with an inner diameter of 2200 mm and a number of stages of 50 stages. There is an outlet for low-boiling impurities and a reflux liquid inlet at the top of the distillation tower (the reflux liquid inlet is connected with the reflux liquid inlet), and there is a bottom outlet for discharging the bottom liquid at the bottom of the tower. , and a circulation port for circulating the second liquid containing refined easily polymerizable substances, there is a treatment liquid supply port at a position between the top of the tower and the bottom of the tower, and the supply port for the treatment liquid is used to supply the liquid containing crude easily The introduction piping of the polymeric substance liquid is connected. In addition, a tank for temporarily storing the bot...

Embodiment 2

[0096] The liquid containing solid insolubles discharged from the wet cyclone separator is passed through a 40-mesh filter to remove solid insolubles, and the second liquid containing refined acrylic acid after passing through the filter is returned to the distillation tower. Run in the same way as Example 1.

[0097] It has been continuously operated in this state and has been operated for 8,000 hours a year. During this period, clogging and the like of the wet cyclone did not occur, and cleaning was not required. In addition, the number of times of cleaning of the filter installed on the liquid supply line of the liquid containing solid insolubles was 333 times / year. In addition, the total amount of acrylic acid lost during 8000 hours of operation was about 2 tons.

Embodiment 3

[0099] In Example 2, the filter equipped in the liquid delivery line of the liquid containing solid insolubles was replaced with a capacity of 50L and a horizontal projected area of 0.07m 2 Gravity settling tank, the supernatant is returned to the distillation column. The gravity settling tank was replaced with the second refined acrylic acid-containing liquid once every two days.

[0100] It has been continuously operated in this state and has been operated for 8,000 hours a year. During this period, clogging and the like of the wet cyclone did not occur, and cleaning was not required. In addition, by introducing into a gravity settling tank, cleaning of the gravity settling tank is unnecessary. In addition, the total amount of acrylic acid lost during 8000 hours of operation was about 1.8 tons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com