Liquid-form emulsion product, method for producing same, and method for using same

A manufacturing method and emulsion technology, applied in the direction of dairy products, cream preparations, sustainable manufacturing/processing, etc., can solve the problems of not reaching the appropriate amount, not being able to completely seal the pouring port 12, and not being able to lie down and place it, and achieve easy Easy to operate, maintain quality and flavor well, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] In this example, a conventional gabled paper container and a gusset bag container with a spout of a different material were filled with the same type of liquid emulsion to manufacture various liquid emulsion products. Hygienic aspects (refrigerated preservation (bacterial reproduction), etc.) are verified. Here, synthetic cream ("Meiji Hokkaido Tokachi Fresh 100" (trade name)) was used as the liquid emulsion.

[0094]

[0095] Here, the conditions of containers (liquid emulsion products) having various shapes, materials, and the like are set as follows.

[0096] (a) "Meiji Hokkaido Tokachi Fresh 100" (using Figure 5 , as explained above)

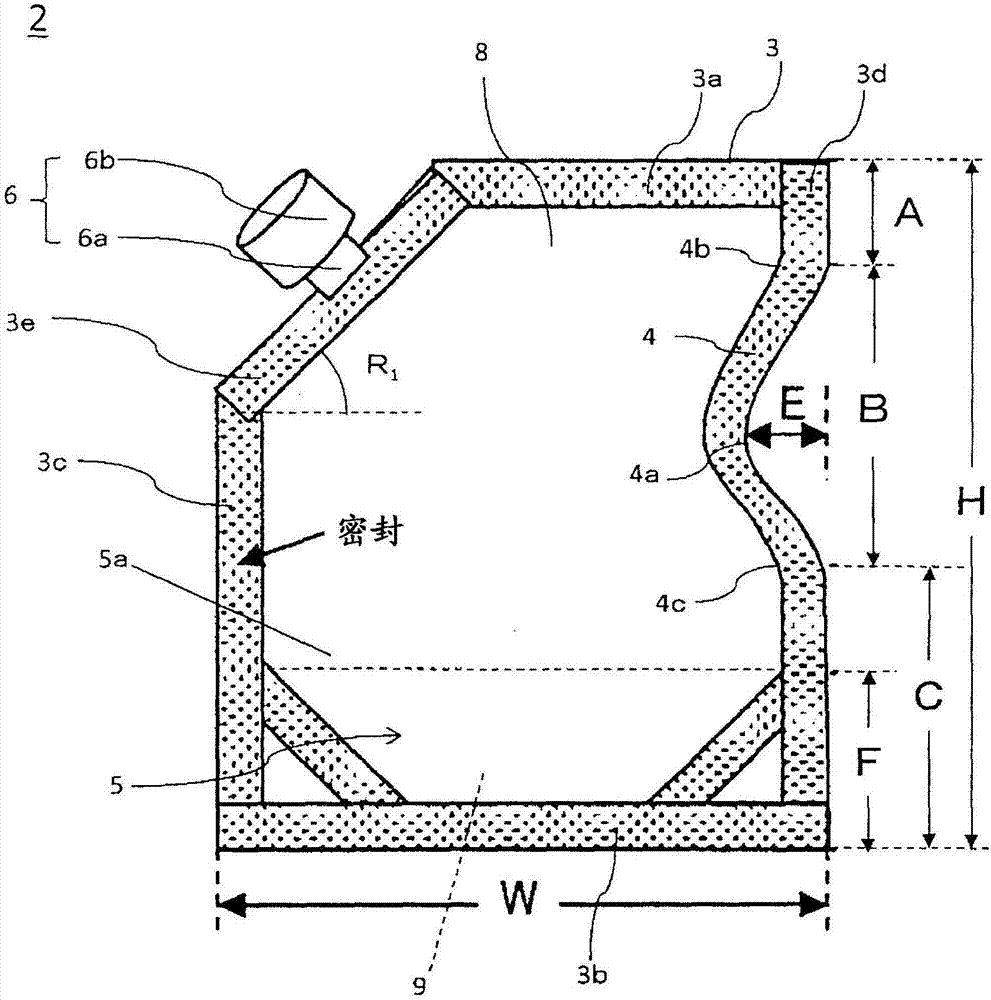

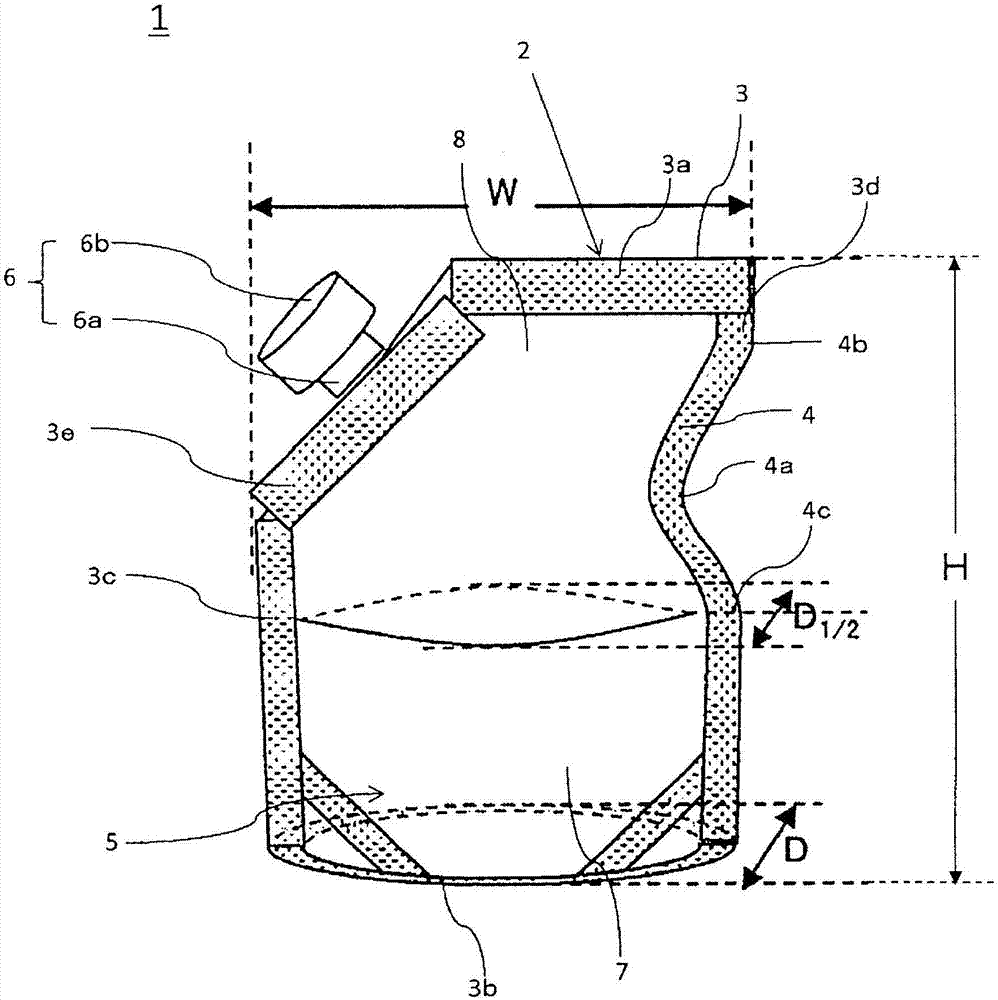

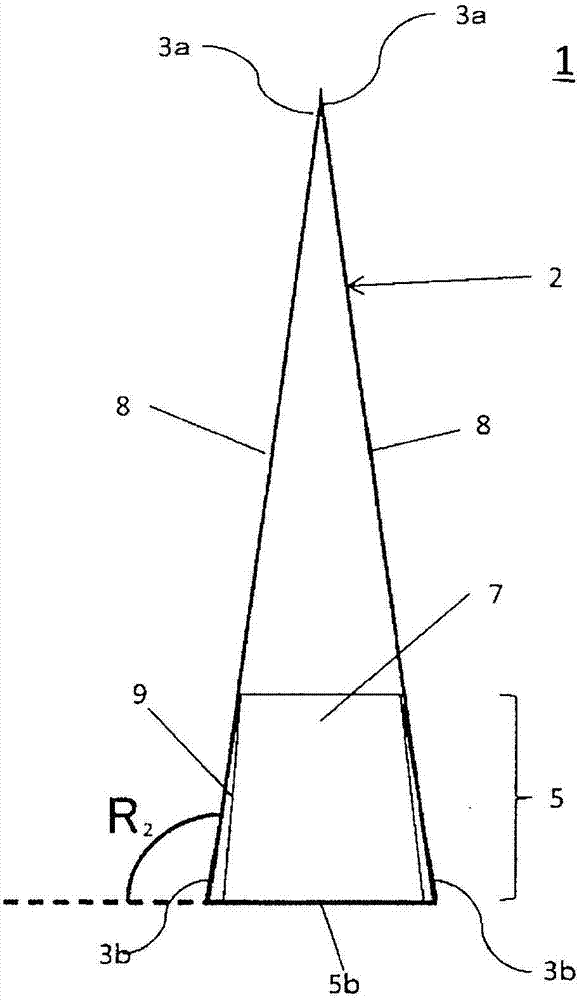

[0097] (b) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as explained above)

[0098] (c) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as explained above)

[0099] It should be noted that in the gusset bag containers with spouts of the above (b) and (c), compared with the conventional...

Embodiment 2

[0105] In this example, a conventional gabled paper container and a gusset bag container with a spout of a different material were filled with the same type of liquid emulsion to manufacture various liquid emulsion products. Quality aspects (progress of oxidation, etc.) are verified. Here, synthetic cream ("Meiji Hokkaido Tokachi Fresh 100" (trade name)) was used as the liquid emulsion.

[0106]

[0107] Here, the conditions of containers (liquid emulsion products) having various shapes, materials, and the like are set as follows. ◎

[0108] (a) "Meiji Hokkaido Tokachi Fresh 100" (using Figure 5 , as explained above)

[0109] (b) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as explained above)

[0110] (c) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as explained above)

[0111] It should be noted that in the gusset bag containers with spouts of the above (b) and (c), compared with the conventional roof-top paper container o...

Embodiment 3

[0118] In this example, a conventional gabled paper container and a gusset bag container with a spout of a different material were filled with the same type of liquid emulsion to manufacture various liquid emulsion products. Flavor aspects (maintenance of aroma components, etc.) were verified. Here, "Meiji Hokkaido Tokachi Fresh 100" (trade name)) of synthetic cream was used as the liquid emulsion.

[0119]

[0120] Here, the conditions of containers (liquid emulsion products) having different shapes, materials, and the like are set as follows.

[0121] (a) "Meiji Hokkaido Tokachi Fresh 100" (using Figure 5 , as described above), the container has been opened.

[0122] (b) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as described above), the container is unsealed and then resealed (ie, recapped).

[0123] (c) "Meiji Hokkaido Tokachi Fresh 100" (using figure 1 , figure 2 , as described above), the container is unsealed and then resealed (ie, reca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com