A visual image-based detection method and device for grain loading status of a grain truck

A technology of loading state and detection method, applied in the field of detection, can solve the problems of harsh working environment of 3D laser scanning sensor, high requirements for operation and maintenance personnel, lack of flexibility and versatility, etc. Stable, easy to implement, fast to detect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

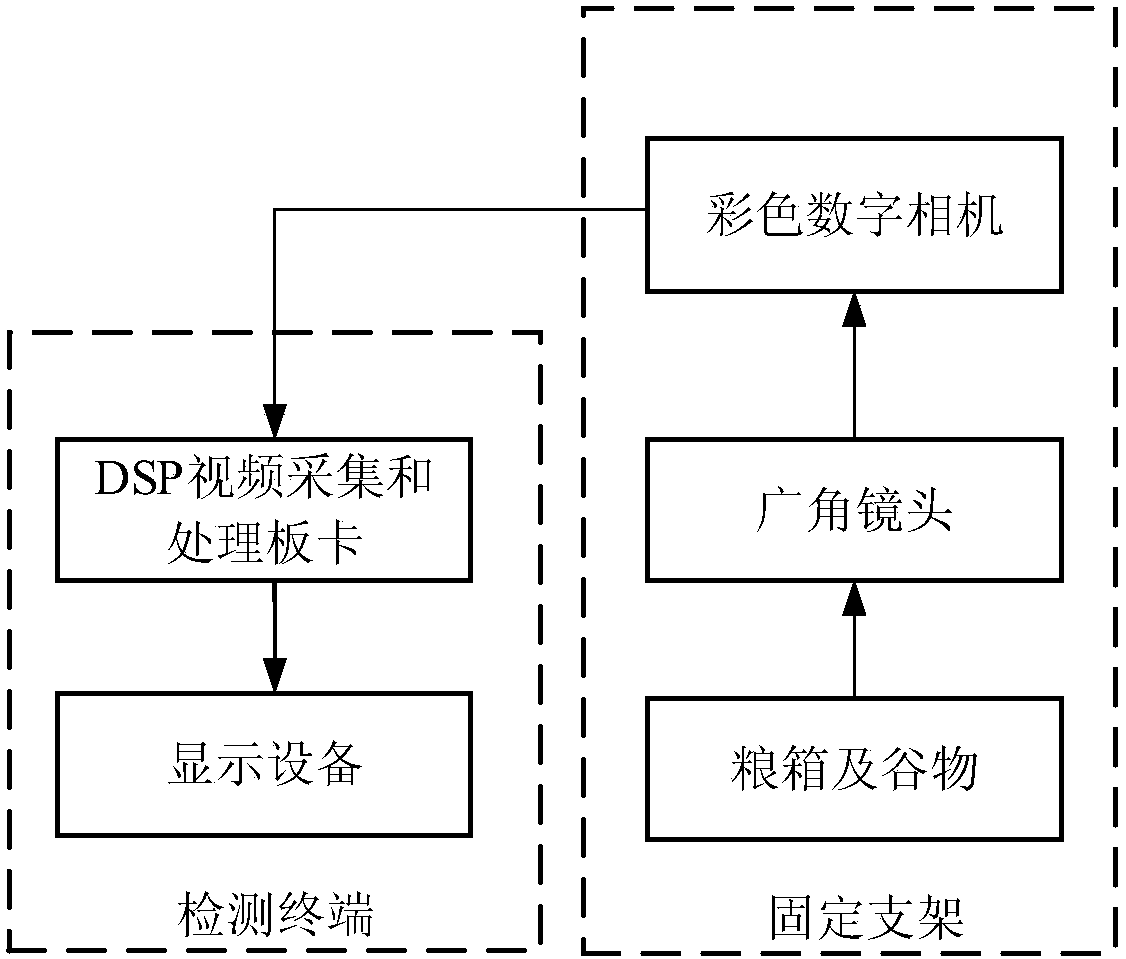

[0050] The present invention aims at the disadvantages of existing measurement methods based on sensors such as machinery, ultrasonic waves, three-dimensional laser scanning, and pressure, such as low efficiency, poor stability, and high cost, and provides a method and device for detecting the grain loading state of a grain transport vehicle based on visual images. Use vision technology to realize real-time detection of grain loading status in grain tanks. The grain distribution state generally includes three states: "not full", "soon to be full" and "already full".

[0051] like figure 1 As shown, the visual image-based grain loading state detection method of the grain truck of the present invention comprises the following steps:

[0052] Step 11, col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com