Isophthalonitrile and/or terephthalonitrile dry capture process

A technology of isophthalonitrile and terephthalonitrile, which is applied in the fields of carboxylic acid nitrile purification/separation, organic chemistry, etc., and can solve problems such as continuous discharge, harsh working environment on site, and difficult cooling of circulating spray water, etc. Achieve the effect of improving the operating environment and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

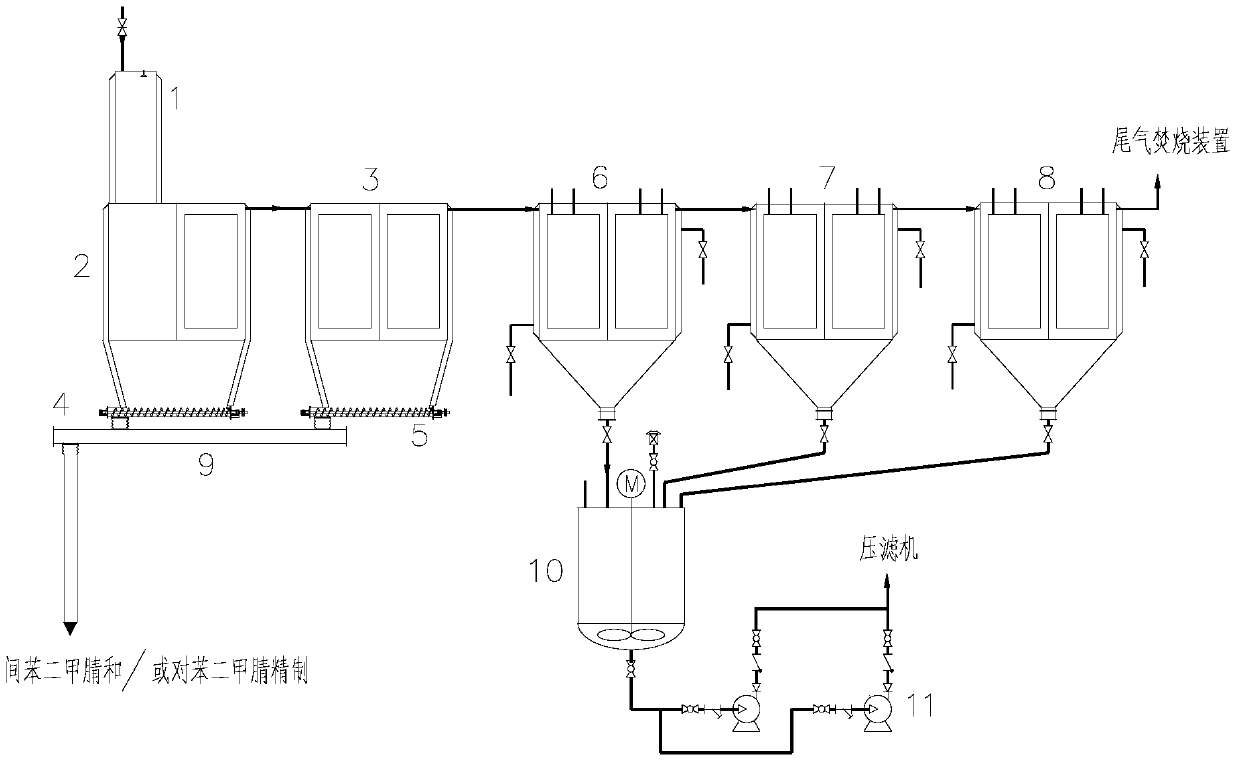

[0023] Isophthalonitrile and / or terephthalonitrile dry capture process, the process is as follows figure 1 Shown:

[0024] The reacted mixed gas at the outlet of the 230°C oil cooler enters the water cooler 1 to cool down. The water cooler 1 is equipped with a liquid atomizing nozzle. The temperature is lowered to 130°C by direct contact with the water mist, and the inner wall of the water cooler is kept at 100°C with a jacket to ensure that the isophthalonitrile and / or terephthalonitrile materials are not precipitated on the inner wall of the water cooler 1. The mixed gas at the outlet of the water cooler 1 enters the primary dry trap 2 and the secondary dry trap 3 in sequence, and the gaseous isophthalonitrile and / or terephthalonitrile enters the primary and secondary dry traps A large amount of precipitation on the inner wall and the surface of the hanging board becomes solid, and the solid isophthalonitrile and / or terephthalonitrile falls to the first-stage crushing at th...

Embodiment 2

[0027] Isophthalonitrile dry capture process, the temperature of the mixed gas after reaction at the outlet of the oil cooler is about 230°C, after being cooled by the water cooler, it enters the dry trap, and the gaseous isophthalonitrile is collected in the dry trap The inner wall of the trap and the surface of the hanging plate are precipitated and become solid, and the solid isophthalonitrile falls to the pulverizing feeder at the bottom of the dry trap by its own gravity and external vibration, and is transported to the dry trap by the scraper feeder after crushing. Refining section.

[0028] The tail gas from the outlet of the dry trap enters the wet trap, the sprayed isophthalonitrile slurry enters the beating kettle, and the beating pump sends the suspended matter slurry in the beating kettle to the filter press for filtration. The tail gas at the outlet of the device enters the tail gas incinerator for treatment.

[0029] In this embodiment, the water cooler adopts a...

Embodiment 3

[0032] Terephthalonitrile dry capture process, the temperature of the mixed gas after reaction at the outlet of the oil cooler is about 230°C, and enters the dry trap after being cooled by the water cooler, and the gaseous terephthalonitrile The inner wall of the trap and the surface of the hanging plate are precipitated and become solid, and the solid terephthalonitrile falls to the crushing feeder at the bottom of the dry trap by its own gravity and external vibration, and is transported to the dry trap by the scraper feeder after crushing. Refining section.

[0033] The tail gas from the outlet of the dry trap enters the wet trap, and the sprayed isophthalonitrile and / or terephthalonitrile slurry enters the beating tank, and the beating pump sends the suspended matter slurry in the beating tank to the pressure filter, and the exhaust gas from the outlet of the wet trap enters the exhaust gas incinerator for treatment.

[0034] In this embodiment, the water cooler adopts a ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com