Automatic filling device for culture medium

An automatic filling and culture medium technology, applied in the direction of synchronous devices, packaging, bottling machines, etc., can solve the problems of unstable filling quality, high risk of dumping, high labor costs, etc., to achieve smooth filling process and reduce The risk of contamination, the effect of ensuring filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

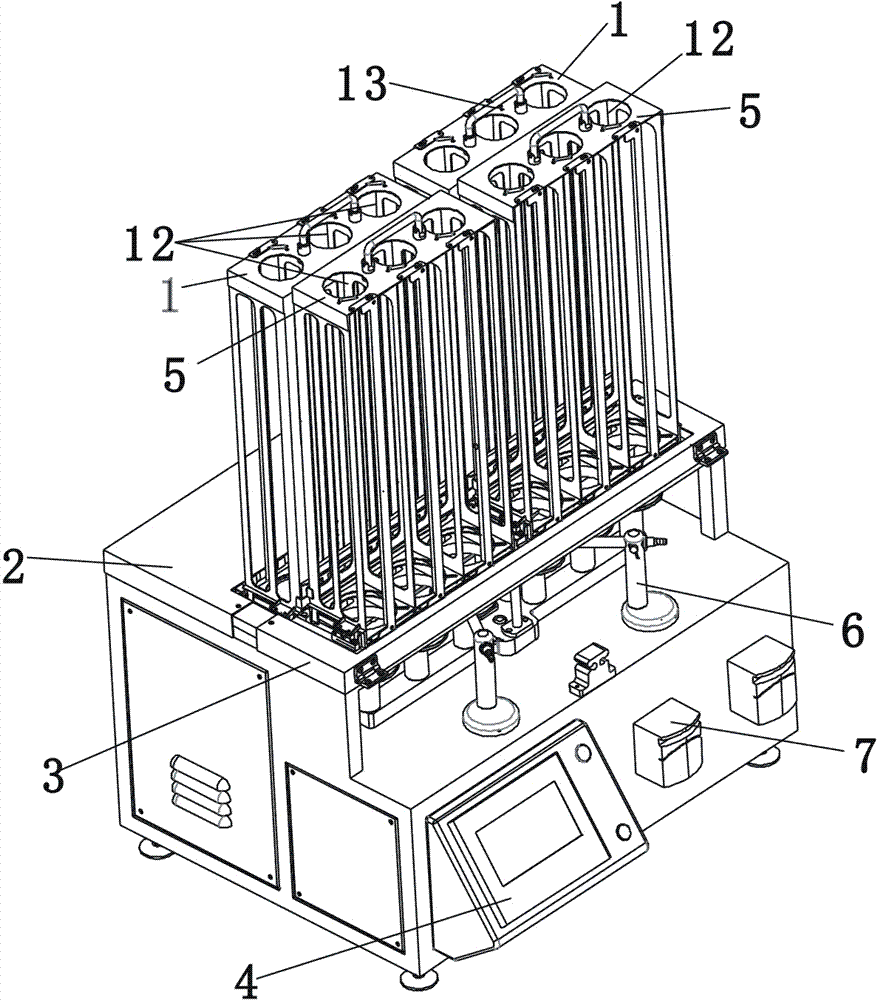

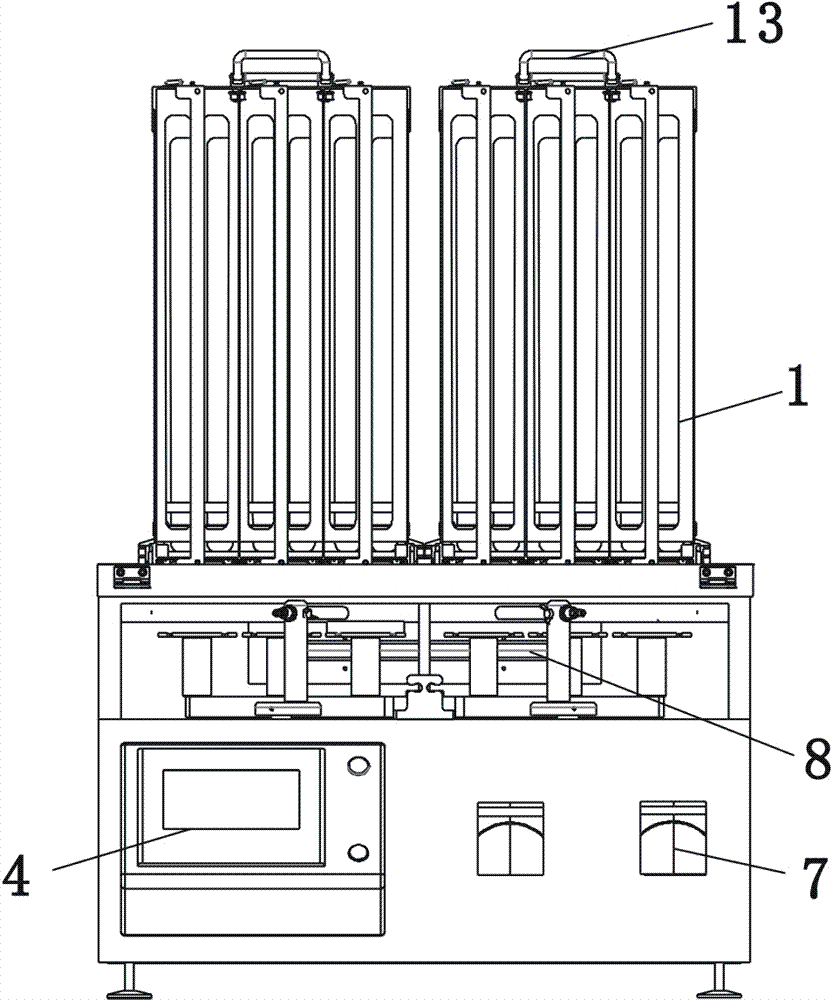

[0041] see Figure 1-7 , this implementation case includes, cabinet 2, control system, operation panel 4 and peristaltic pump 7 that are arranged on the front of cabinet 2, cabinet 2 is provided with one or more first stations 21, and one or more first stations 21 corresponds to the second station hole 22, the filling station corresponding to the liquid outlet pipe below the second station hole 22, the push plate mechanism 9 that pushes the empty plate from the first station to the second station hole, and Including the lifting mechanism 10, the lifting mechanism 10 is provided with a plate tray 101 corresponding to the second station hole 22 one by one. According to the corresponding process, it is lifted and operated above the second stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com