Screw-type table tennis racket rubber trimmer

A table tennis racket and screw technology, applied in the field of screw table tennis racket rubber trimmers, can solve the problems of scratching the bottom plate, low efficiency, difficult operation, etc., and achieve the effect of reducing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

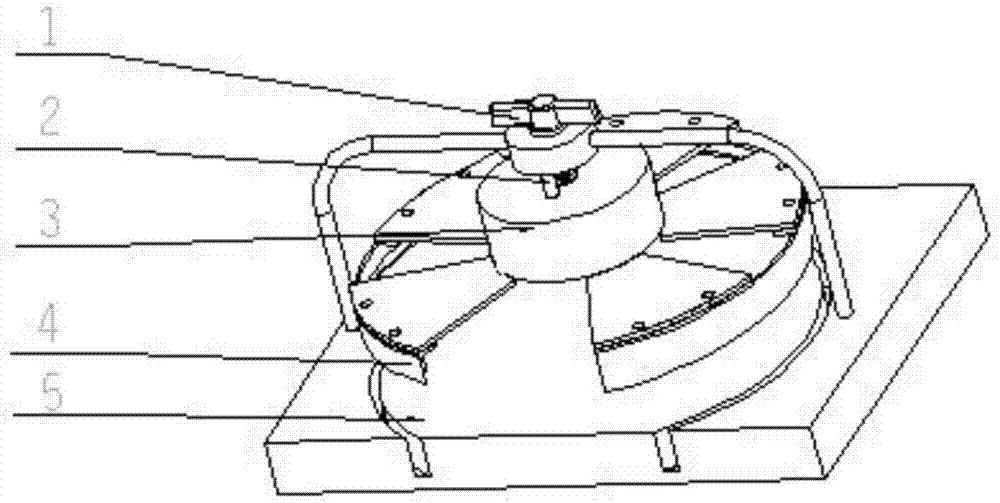

[0021] like figure 1 As shown, the spiral table tennis racket rubber trimmer of the present invention includes a spiral manipulator, a guide rod, a presser, an annular blade and a base. Composed of a cylinder and five pressing pieces, the lower peripheral surface of the annular cylinder is respectively connected to the top edges of the five pressing pieces, and the bottom edge of each pressing piece is connected to the upper part of the annular blade through bolts; the top ends of the two guide rods arranged symmetrically are connected to the circular The ring is fixed, the tops of the two symmetrically arranged columns are respectively fixed with the ring, the bottom ends of the symmetrically arranged two columns are respectively connected with the base, the lower ends of the two symmetrically arranged guide rods are connected with the circular cylinder of the presser thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com