Manufacturing process of double-opening vacuum cup

A technology of vacuum insulation and manufacturing process, which is applied to drinking utensils and other directions, can solve the problems of lack of insulation function and single storage space for double-mouth cups, and achieve the effect of improving the effect of vacuuming and ensuring the effect of vacuuming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A manufacturing process of a double-mouth vacuum insulation cup, comprising the following steps:

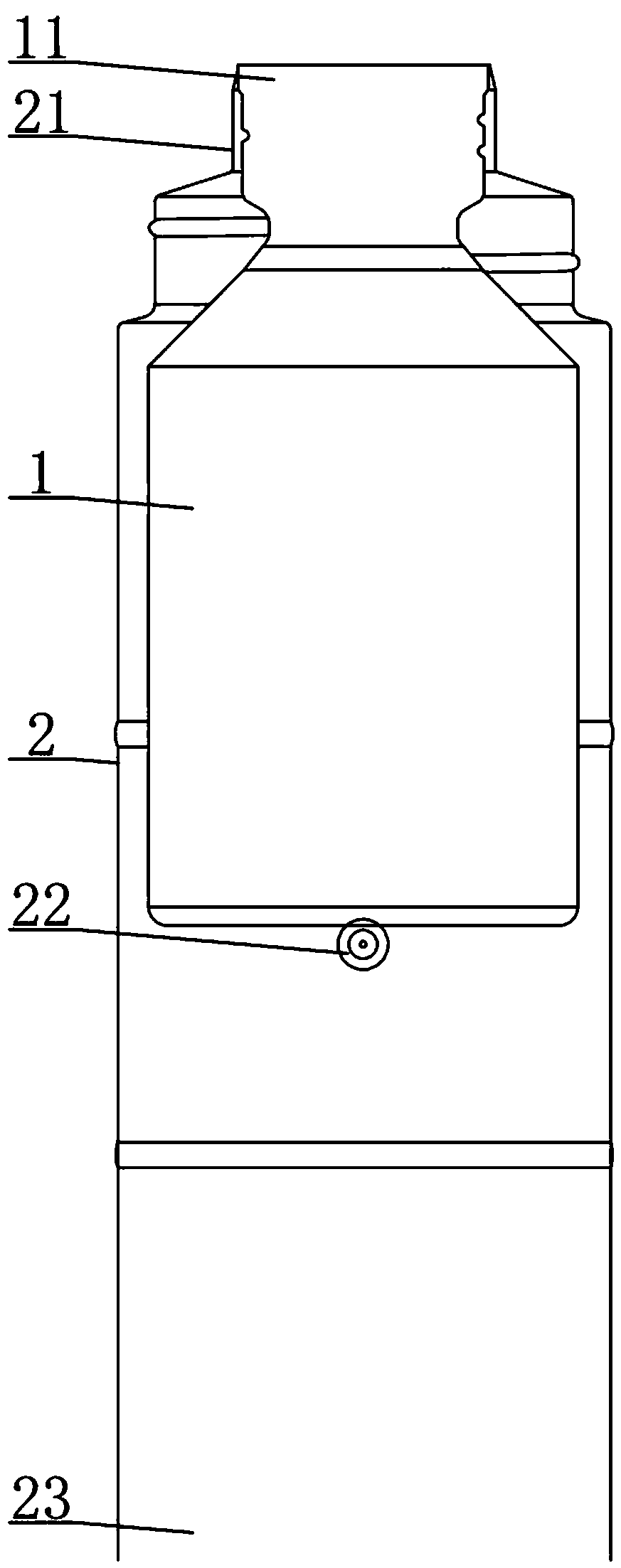

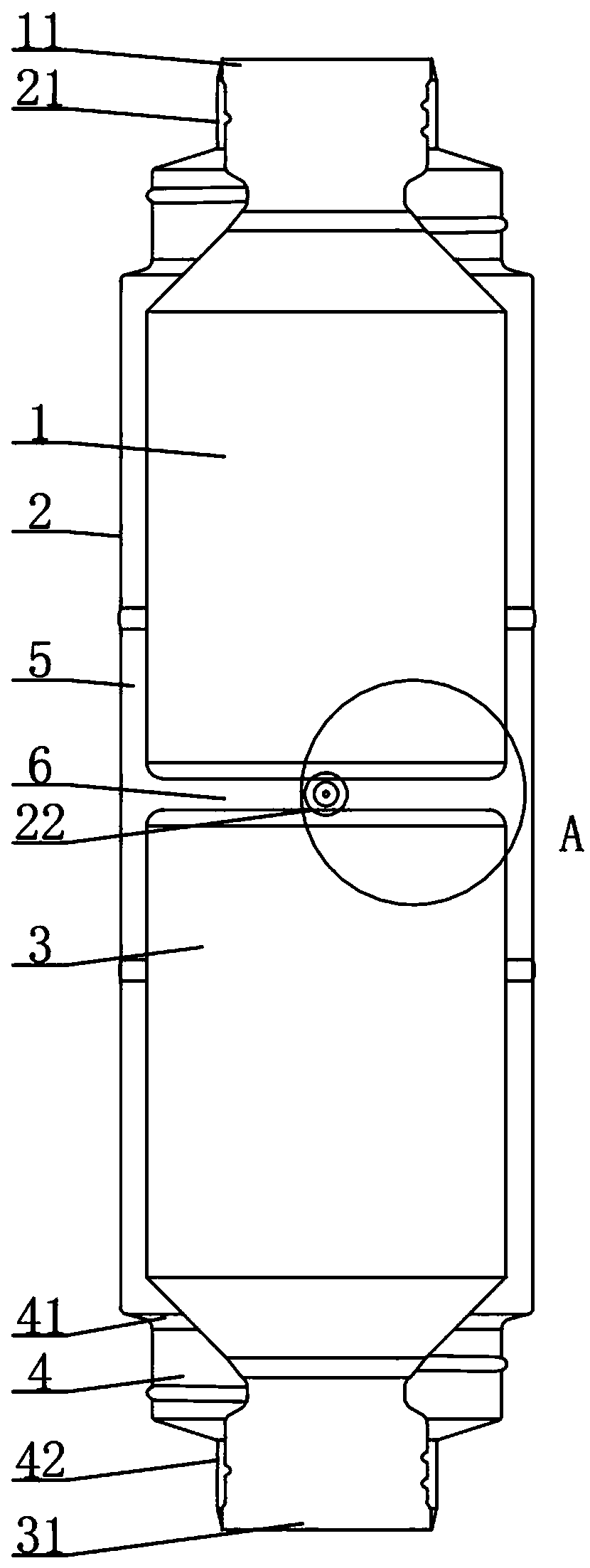

[0034] (a) Take a first inner tank 1, the first inner tank 1 is provided with a first opening 11, and a hollow first shell 2 is taken, and the two ends of the first shell 2 are respectively provided with The first upper opening connecting portion 21, the first lower opening connecting portion 23, the first casing 2 is provided with a vacuum hole 22;

[0035] (b) Put the first liner 1 into the first shell 2, make the first opening 11 of the first liner 1 fit with the first upper opening connection portion 21 of the first shell 2, Welding the first opening portion 11 and the first upper opening connecting portion 21 to form a first-stage semi-finished product;

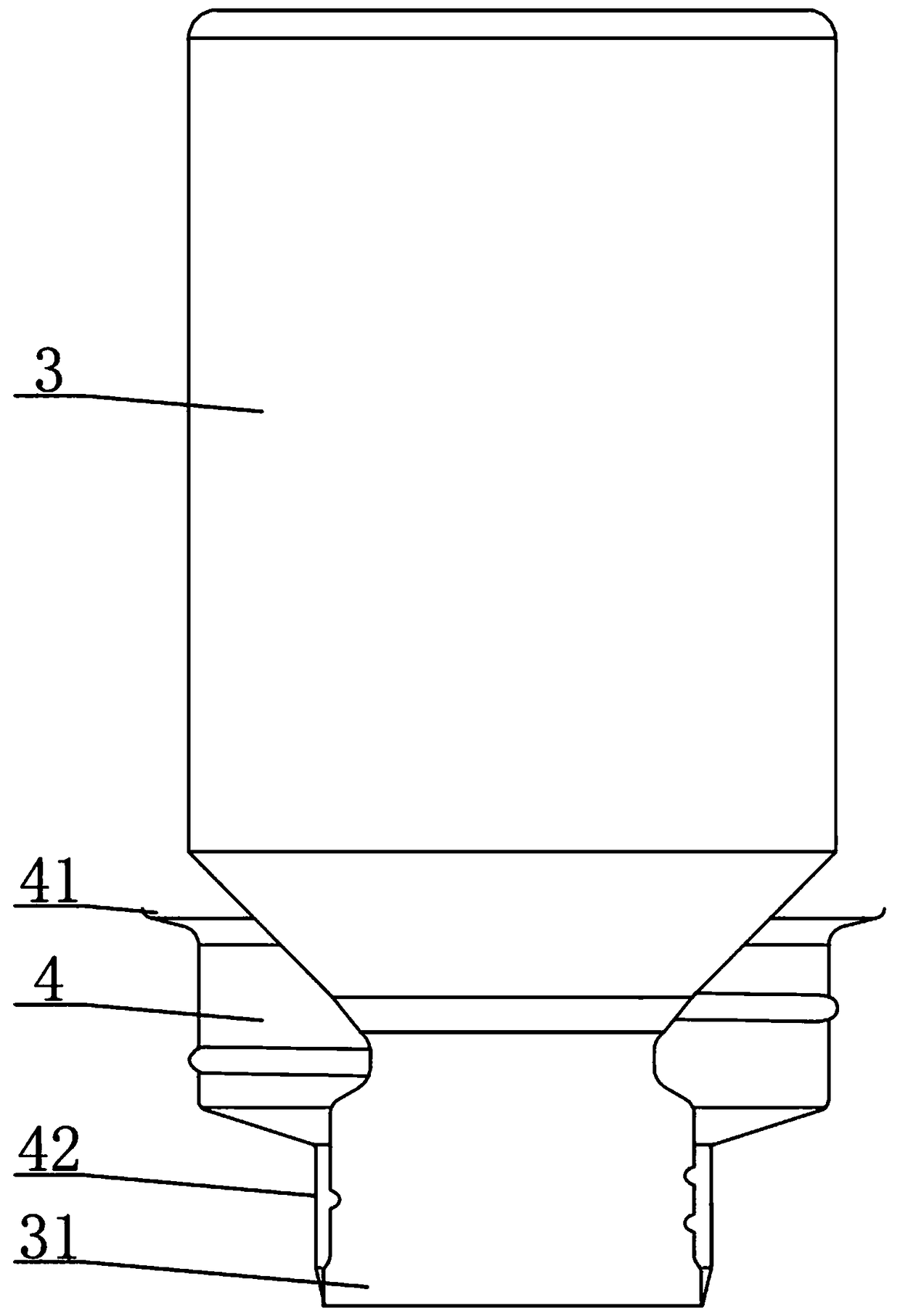

[0036] (c) Take a second liner 3, the second liner 3 is provided with a second opening 31, take a hollow second shell 4, the two ends of the second shell 4 are respectively provided with The second upper opening co...

Embodiment 2

[0047] A manufacturing process of a double-mouth vacuum insulation cup, comprising the following steps:

[0048] (a) Take a first inner tank 1, the first inner tank 1 is provided with a first opening 11, and a hollow first shell 2 is taken, and the two ends of the first shell 2 are respectively provided with The first upper opening connecting portion 21, the first lower opening connecting portion 23, the first casing 2 is provided with a vacuum hole 22;

[0049] (b) Put the first liner 1 into the first shell 2, make the first opening 11 of the first liner 1 fit with the first upper opening connection portion 21 of the first shell 2, Welding the first opening portion 11 and the first upper opening connecting portion 21 to form a first-stage semi-finished product;

[0050] (c) Take a second liner 3, the second liner 3 is provided with a second opening 31, take a hollow second shell 4, the two ends of the second shell 4 are respectively provided with The second upper opening co...

Embodiment 3

[0061] A manufacturing process of a double-mouth vacuum insulation cup, comprising the following steps:

[0062] (a) Take a first inner tank 1, the first inner tank 1 is provided with a first opening 11, and a hollow first shell 2 is taken, and the two ends of the first shell 2 are respectively provided with The first upper opening connecting portion 21, the first lower opening connecting portion 23, the first casing 2 is provided with a vacuum hole 22;

[0063] (b) Put the first liner 1 into the first shell 2, make the first opening 11 of the first liner 1 fit with the first upper opening connection portion 21 of the first shell 2, Welding the first opening portion 11 and the first upper opening connecting portion 21 to form a first-stage semi-finished product;

[0064] (c) Take a second liner 3, the second liner 3 is provided with a second opening 31, take a hollow second shell 4, the two ends of the second shell 4 are respectively provided with The second upper opening co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com