An automatic brushing device for c/c material surface

An automatic and brushing technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of poor brushing effect and high labor intensity, and achieve fast brushing speed, low labor intensity and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

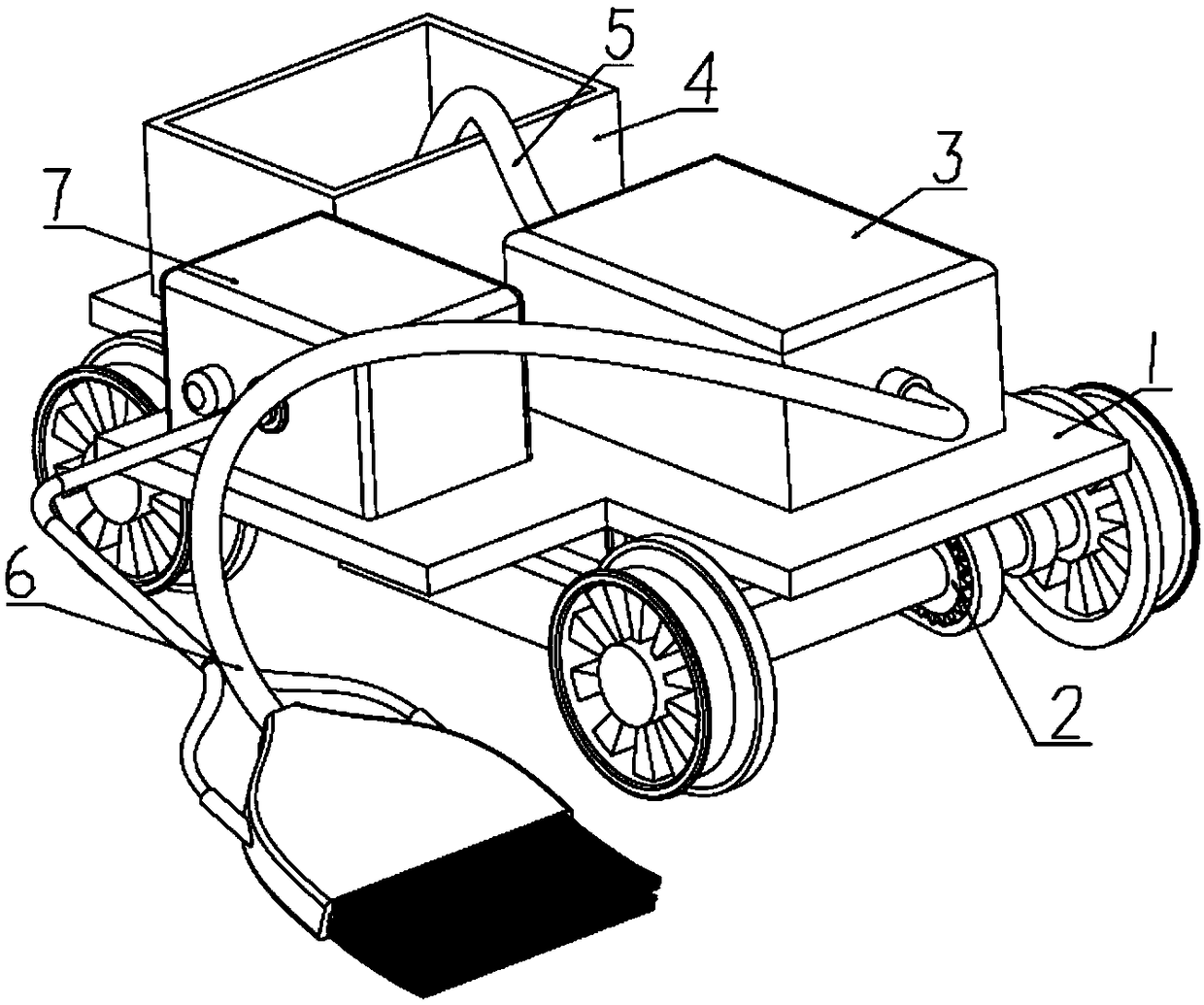

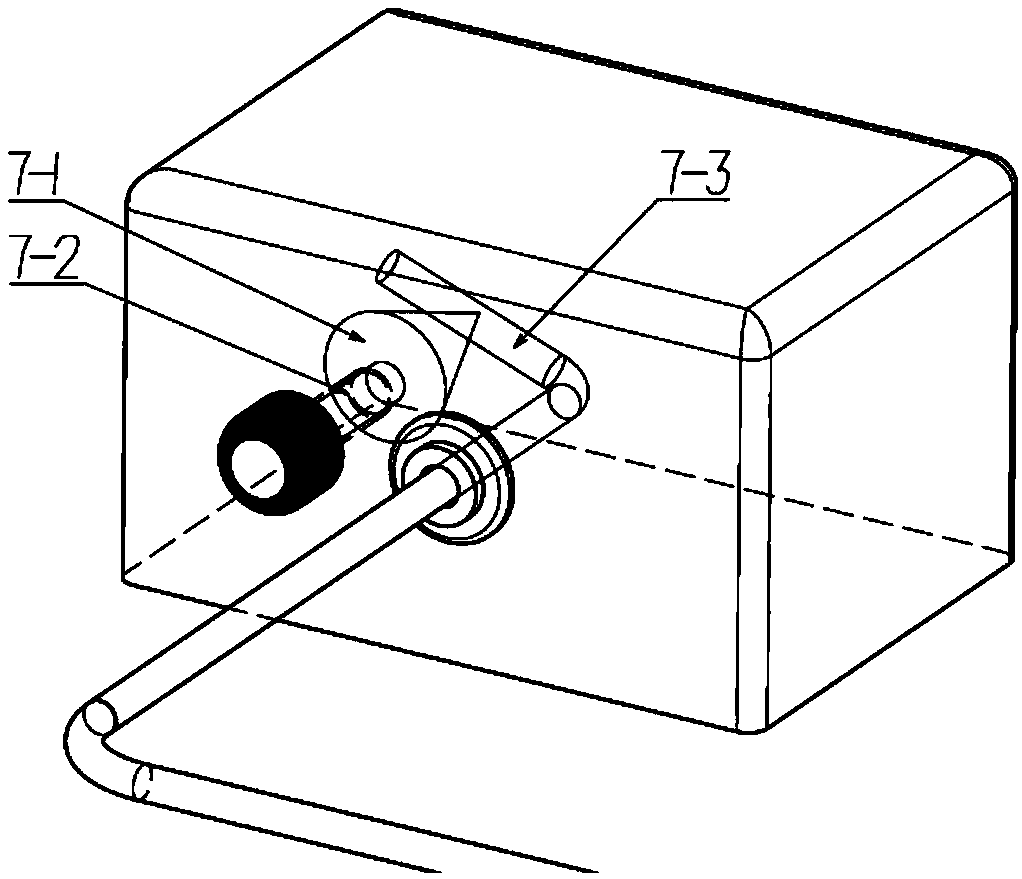

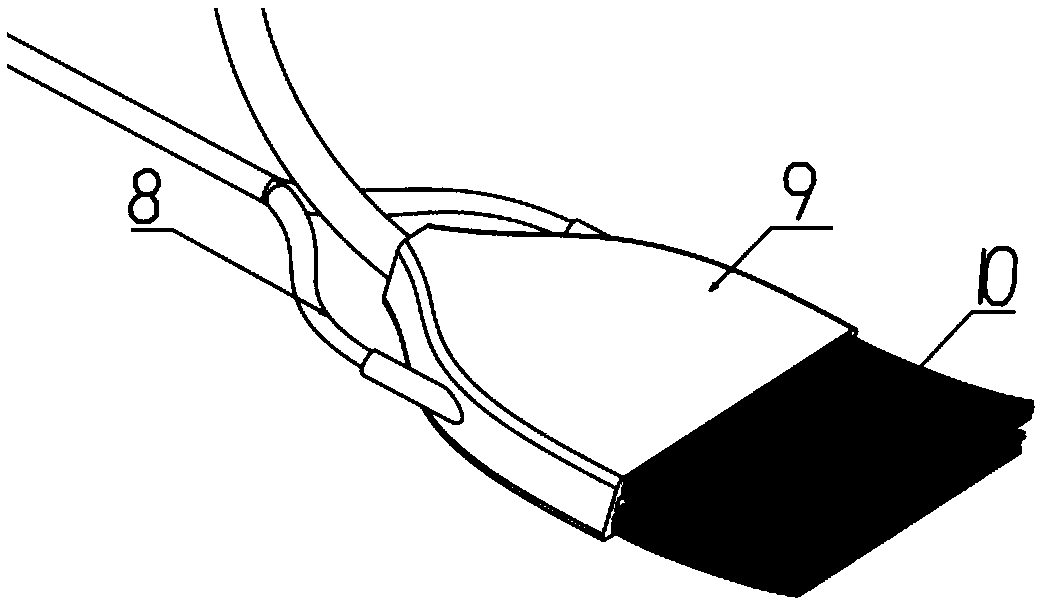

[0016] Such as Figure 1 to Figure 3 As shown, an automatic brushing device for the surface of C / C materials includes a rail car 1, a drive motor is installed on the chassis of the rail car 1 through a motor base, and the drive motor drives the rotating shaft to rotate, and the rotating shaft and the front and rear axles pass through the belt Connect, constitute drive mechanism 2 of the present invention, and drive mechanism 2 provides forward driving force for the present invention; Delivery pump 3 is installed on described rail car 1; Described delivery pump 3 one ends link to each other with paint tank 4 by feed pipe 5, The other end is connected to the brush holder 8 through the discharge pipe 6; the delivery pump 3 is equipped with a regulating valve to adjust the feed flow. A brushing mechanism fixing device 7 is installed on the rail car 1, and the fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com