Exhaust gas particulate matter trapping device and control method thereof

A technology of exhaust particles and exhaust gas, which is applied in the direction of electronic control of exhaust treatment devices, exhaust devices, noise reduction devices, etc. (The thermal stress of the filter element is large, so as to reduce the number of regenerations, promote collision and friction, and reduce the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

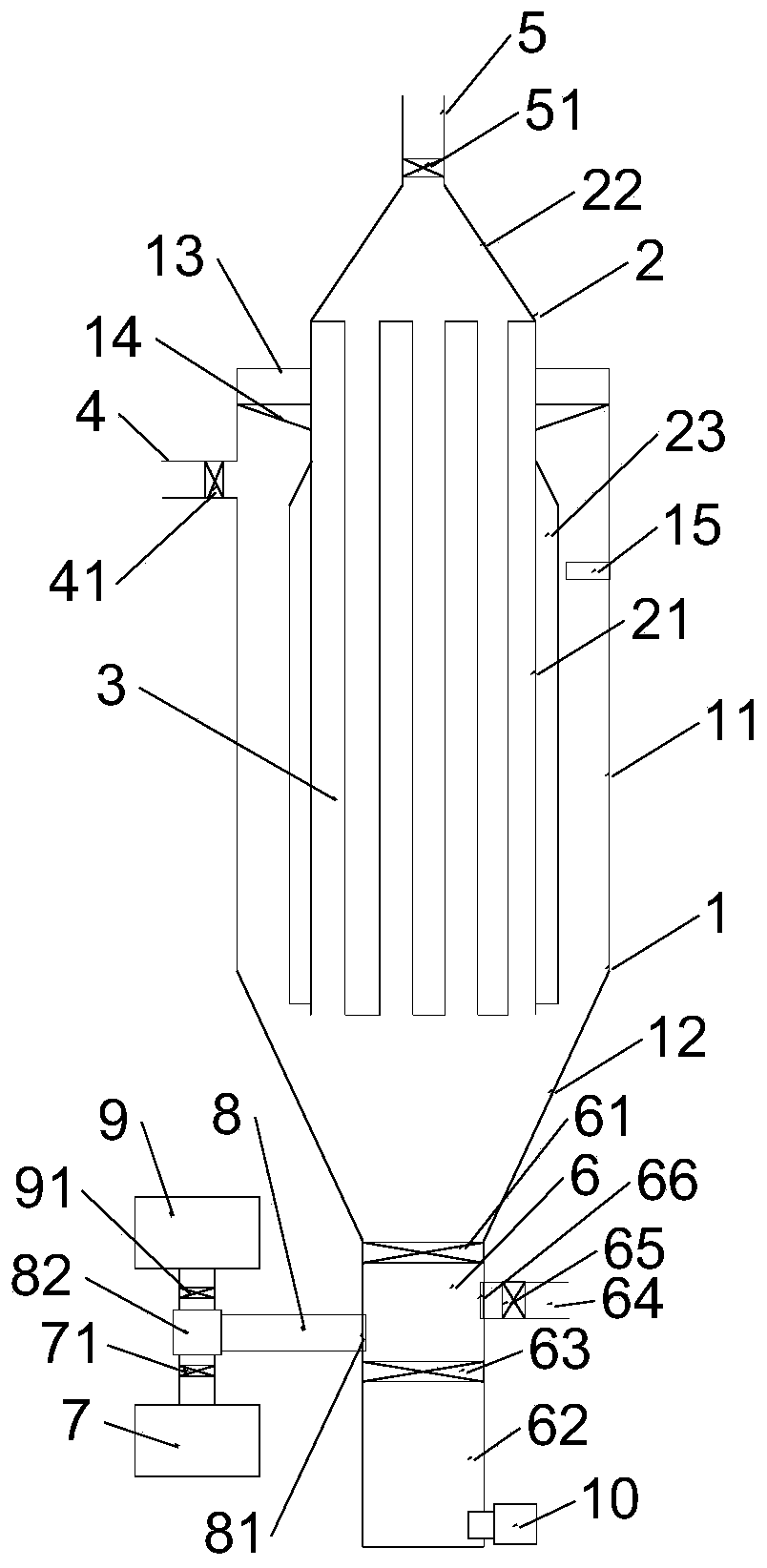

[0039] like figure 1 As shown, the present invention provides an exhaust particulate matter trapping device, comprising:

[0040] The first housing 1 is arranged vertically, and includes an integrally formed first cylindrical portion 11 and a first conical portion 12, the first cylindrical portion 11 is located directly above the first conical portion 12 and vertically penetrated ;

[0041] The second housing 2 is arranged vertically and includes an integrally formed second cylindrical portion 21 and a second conical portion 22. The second cylindrical portion 21 is located directly below the second conical portion 22 and is vertically connected. , the second cylindrical portion 21 is disposed inside the first cylindrical portion 11, and the upper portion of the second cylindrical portion 21 is connected to the upper portion of the first cylindrical portion 11 through a bearing 13;

[0042] A filter element 3, which is filled in the second cylindrical portion 21, the filter e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com