Building 3D printing head with function of automatic injecting of additive

An automatic injection and admixture technology, which is applied in the direction of construction, building construction, and building materials processing, can solve the problems of slowing down printing speed, slow condensation speed, and reducing printing efficiency, and achieve the effect of improving printing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

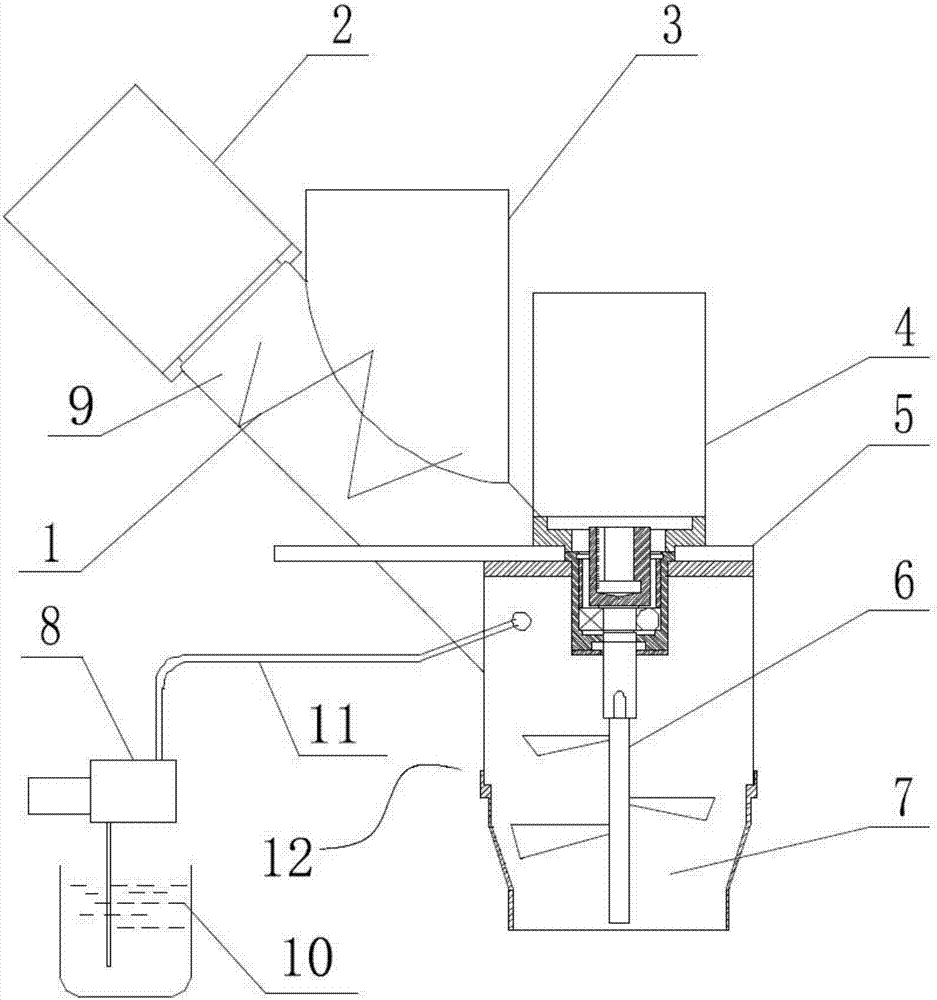

[0016] Attached below figure 1 The present invention is described further:

[0017] A construction 3D printing head with the function of automatically injecting additives, the feed pipe 3 is connected to the material propulsion pipe 9, and one end of the material propulsion pipe 9 is provided with a propulsion motor 2, and the propulsion motor 2 is connected to the propeller 1 located in the material propulsion pipe 9, The other end of the material propulsion pipe 9 is connected to the mixing chamber 7, and the admixture storage device 10 is connected to the mixing chamber 7 through the admixture delivery pipe 11. The stirring chamber 7 is provided with a stirring blade for stirring, and the stirring blade is located on the stirring shaft 6 , the stirring shaft 6 is connected to the stirring shaft motor 4.

[0018] The admixture delivery pipe 11 is provided with an admixture delivery pump 8, and the admixture delivery pump 8 is connected to a control system.

[0019] The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com