Excavation method of reverse construction method-constructed foundation pit

An inverse method and foundation pit technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of prolonged construction period, limited operating space, difficult excavation construction, etc., saving construction period, avoiding repair work, and shortening construction. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Taking advantage of the characteristics of hydraulic excavation technology, it solves the problems of difficulty in earthwork excavation and transportation, low efficiency, superstructure construction affected by foundation pit excavation, foundation pit construction affected by weather, etc. .

[0024] A method for excavating a foundation pit by the reverse method, comprising the following contents:

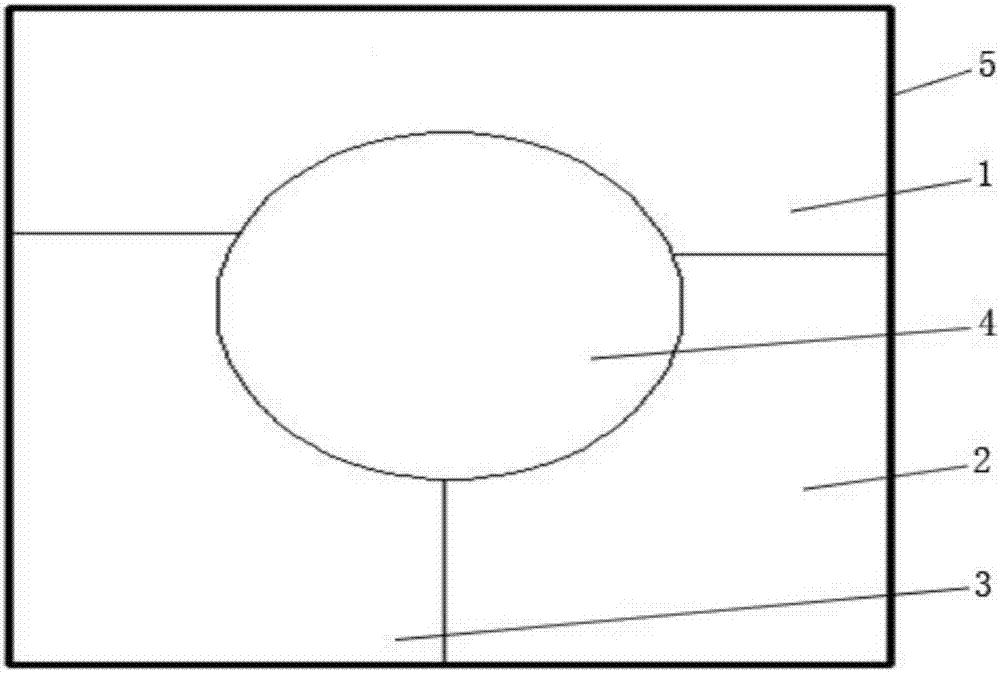

[0025] 1) For the setting of the surrounding structure of the foundation pit, a continuous wall is set around the foundation pit 5, and partitions are carried out according to the buildings above the foundation pit to determine the forward operation area and the reverse operation area, such as figure 1 As shown, the construction foundation pit is divided into: the reverse operation area 1, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com