Jacquard knitting structure of arc-shaped knitting track and knitting method

A technology of arc-shaped structure and jacquard needles, applied in the field of knitting, can solve the problems of restricting the development of new products, the quality of knitted fabrics, the inability to set needle grooves and knitting needles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

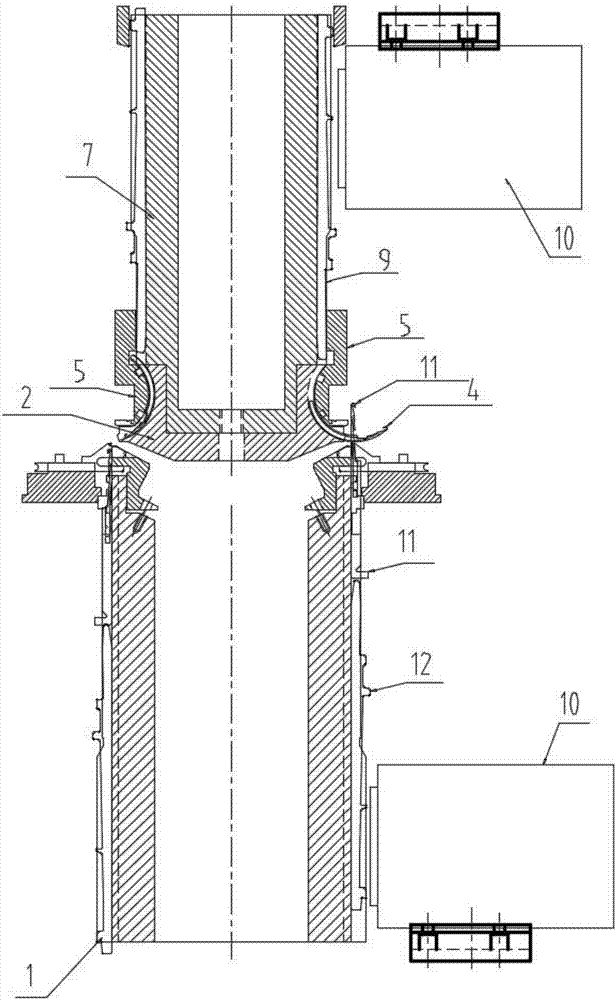

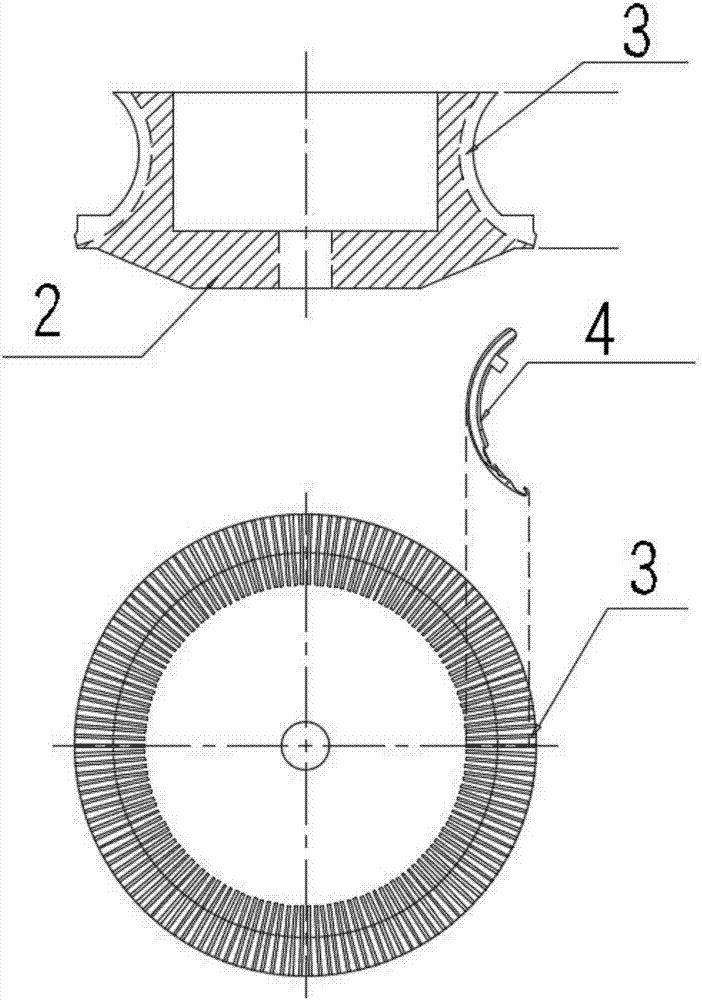

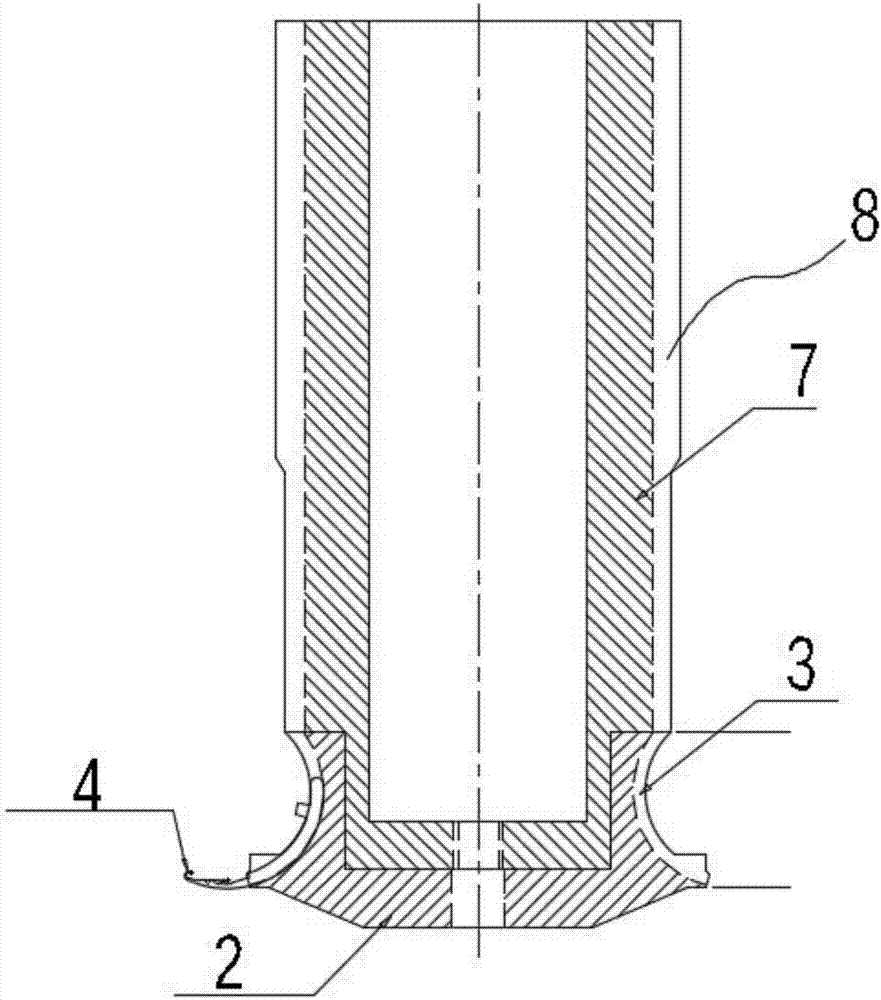

[0041] A jacquard movement mechanism with an arc-shaped movement track, such as figure 1 and figure 2 As shown, it includes the lower needle cylinder 1, the lower needle cylinder 1 is provided with an arc-shaped dial 2, and a number of arc-shaped needle grooves 3 are arranged on the side of the arc-shaped needle disk 2, and the loop-transfer knitting needles are arranged in the arc-shaped needle groove 3 4. A plurality of arc-shaped needle grooves 3 are set on the perimeter of the unit diameter.

[0042] Specifically, the transfer knitting needle 4 is an arc-shaped structure matched with the arc-shaped needle groove 3, and the structure of the transfer knitting needle 4 is as follows: Figure 4 As shown, the needle bar 41 is included, the front end of the needle bar 41 is provided with a needle hook 42, the front part of the needle bar 41 is provided with a needle latch 43 matching with the needle hook 42, and the needle bar 41 rear or middle part is provided with a needle h...

Embodiment 2

[0047] A jacquard movement mechanism with an arc-shaped movement track, such as figure 1 and figure 2 As shown, as shown, it includes an upper needle cylinder 7 and a lower needle cylinder 1, and the lower needle cylinder 1 is provided with an arc-shaped dial 2, and several arc-shaped needle grooves 3 are arranged on the side of the arc-shaped needle disk 2, and the arc-shaped needle grooves Knitting needle 4 is arranged inside 3, and needle selector 10 is arranged on upper needle cylinder 7.

[0048] Specifically, the transfer knitting needle 4 is an arc-shaped structure matched with the arc-shaped needle groove 3, and the structure of the transfer knitting needle 4 is as follows: Figure 4 As shown, the needle bar 41 is included, the front end of the needle bar 41 is provided with a needle hook 42, the front part of the needle bar 41 is provided with a needle latch 43 matching with the needle hook 42, and the needle bar 41 rear or middle part is provided with a needle hook...

Embodiment 3

[0054] A needle-moving method based on Embodiment 1 and Embodiment 2. The stitch-transfer knitting needle 4 makes loops and stitch-transfer actions in the needle track 6. The specific needle track is an arc track, and its track is composed of an arc The needle movement mechanism 5 is confirmed. The specific stitching process is as follows: Figure 8 as shown, Figure 8 It is a schematic diagram of the present invention working on a circular knitting machine without sinker mechanism. Figure 8 On the circular knitting machine in Figure 7 Form a circle with the cooperation of .

[0055] As a further improvement, the radian of the arc-shaped needle groove is set in the range of π / 4-π / 3, and the angle between the tangent line of the bottom opening of the arc-shaped needle groove and the horizontal is 30-45 degrees.

[0056] There is an essential difference between the curved needle track and the ordinary knitting needle track. Due to the different needle movement methods, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com