Rubber composition and pneumatic tire formed from said rubber composition

A rubber composition and rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of rubber composition hardness increase, processability deterioration, low fuel consumption and wear resistance, etc. Achieve good processability, improve low fuel consumption and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] The present invention is specifically described based on examples, but the present invention is not limited to them.

[0116] Various chemicals used in the production examples are described below.

[0117]Ion-exchanged water: manufactured by our company

[0118] Potassium rosinate soap: manufactured by Harima Chemicals, INC.

[0119] Fatty acid sodium soap: manufactured by Wako Pure Chemical Industries, Ltd.

[0120] Potassium chloride: manufactured by Wako Pure Chemical Industries, Ltd.

[0121] Sodium naphthalenesulfonate formaldehyde condensate: manufactured by Kao Co., Ltd.

[0122] Styrene: Styrene manufactured by Wako Pure Chemical Industries, Ltd.

[0123] 1,3-butadiene: 1,3-butadiene manufactured by Takachiho Shoji Co., Ltd.

[0124] Tert-dodecyl mercaptan: tert-dodecyl mercaptan (chain transfer agent) manufactured by Wako Pure Chemical Industries, Ltd.

[0125] Sodium hydrosulfide (sodium hydrosulfide): manufactured by Wako Pure Chemical Industries, Ltd. ...

manufacture example 1

[0137] A stainless steel polymerization reactor with an internal volume of 50 liters was washed, dried, and replaced with dry nitrogen, and then 3,000 g of 1,3-butadiene, 2,000 g of styrene, 5.74 g of t-dodecyl mercaptan, and the above-mentioned emulsifier were added. 9688g, sodium hydrosulfide 6.3ml (1.8M), active agent (FeSO 4 / EDTA / rongalit) 6.3 ml each, and 6.3 ml (2.3 M) of the polymerization initiator were polymerized at 10° C. for 3 hours while stirring. After the polymerization, add 2.9g of N,N-diethylhydroxylamine, carry out the reaction for 30 minutes and take out the contents of the polymerization reaction vessel, add 10g of 2,6-di-tert-butyl-p-cresol, and evaporate most of the water , and then dried under reduced pressure at 55°C for 12 hours to obtain Copolymer 1.

manufacture example 2

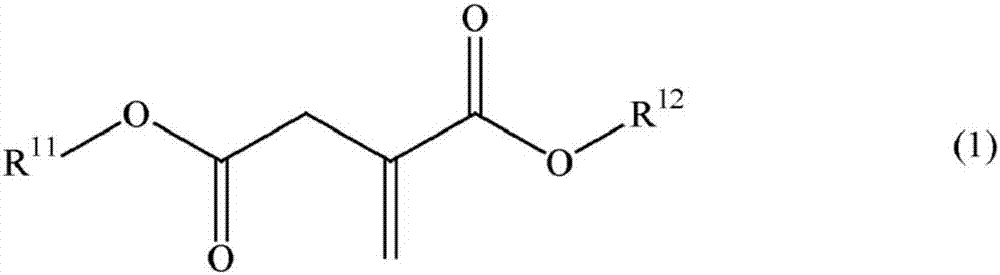

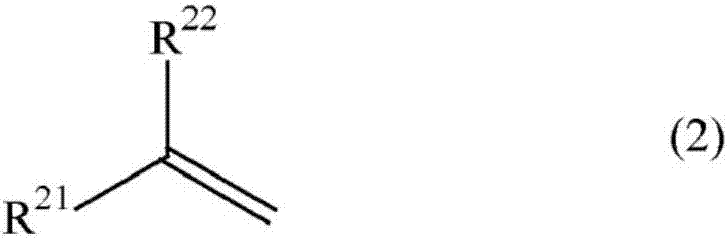

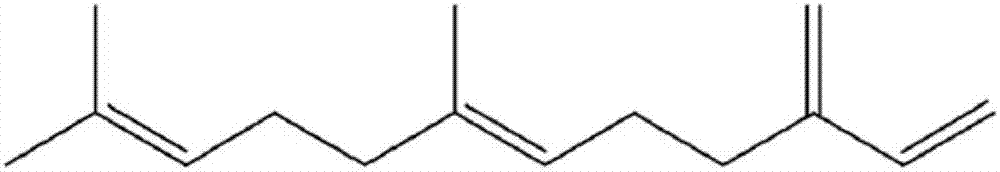

[0139] 3000 g of 1,3-butadiene and 2000 g of styrene in Production Example 1 above were changed to 2500 g of 1,3-butadiene, 1000 g of styrene, 1000 g of farnesene, and 500 g of diethyl itaconate (IDE), except Otherwise, it was manufactured by the same method, and the copolymer 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com